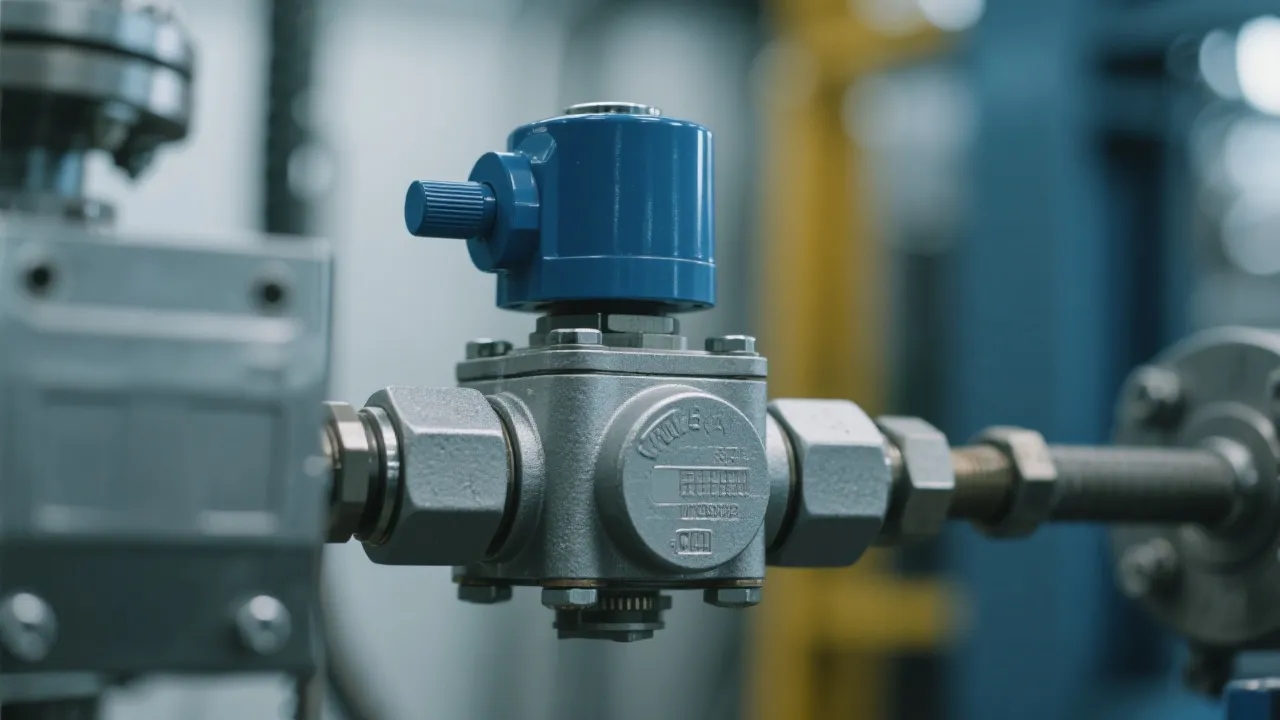

Proportional valves are crucial components in fluid control systems, offering precise regulation of flow rates and pressure. These valves are integral to multiple industries, enhancing system effectiveness and efficiency. This guide explores their functions, advantages, and industry applications in detail, showcasing their indispensable role in modern engineering.

In the realm of fluid control systems, proportional valves stand out for their ability to deliver precise regulation of flow rates and pressure. These essential components are pivotal in ensuring system responsiveness and reliability across various industries, including manufacturing, automotive, and aerospace. Their application ranges from controlling hydraulic systems to optimizing pneumatic processes, underlining their versatility and indispensability. By adjusting the flow of the medium based on specific demands, proportional valves enable systems to operate more smoothly and efficiently. Their importance cannot be overstated, as they directly influence the functionality and overall efficiency of a wide array of machinery and equipment.

Proportional valves function by adjusting the opening and closing of the valve based on the input signal, which could be electrical or hydraulic. This flexibility allows for fine-tuned control of the flow and pressure of the medium passing through them. Unlike ON/OFF valves, which are limited to binary states, proportional valves can operate over a continuous range, providing superior control and energy efficiency. The operational principle relies on the use of a feedback loop that monitors the output (pressure or flow) and dynamically adjusts the valve position to maintain desired values. This method of operation is crucial in applications where fluctuations in demand or environmental conditions may occur. It emphasizes the importance of precision in system controls and the ability to react in real-time to changes.

The primary advantage of proportional valves is their ability to enhance system performance through precise control. Additional benefits include:

Proportional valves find applications in several industries due to their versatility. In the automotive sector, they contribute to more responsive steering and braking systems, enhancing driver control and safety. The aerospace industry employs them for precise fuel and air mixing, critical for engine efficiency and emissions control. In manufacturing, these valves help regulate processes such as die casting and plastic molding, improving product quality by ensuring consistent material flow and temperature control. Additionally, they are essential in the robotics field for precise motion control, allowing for complex movements and tasks to be executed with accuracy and repeatability.

Apart from these primary industries, proportional valves are increasingly utilized in renewable energy systems such as wind and solar power. They play a key role in optimizing the performance of hydraulic and pneumatic systems used in these technologies. Similarly, in the medical field, proportional valves are vital for controlling fluid delivery in applications like infusion pumps and automated surgical devices, where precision is paramount.

Proportional valves are characterized by their specific technical features, which include:

Choosing a proportional valve involves considering several factors such as system requirements, flow characteristics, and budget constraints. It is a process that encompasses understanding the specific needs of the application, including the types of fluids handled and the necessary environmental conditions. Industry professionals often consult with suppliers and technical experts to determine the top fit for their specific application needs. Factors to consider during selection include:

By taking into account these various factors, companies can minimize complications during installation and ensure optimal performance from their chosen valves.

| Question | Answer |

|---|---|

| What differentiates proportional valves from ON/OFF valves? | Proportional valves offer a range of positions for smoother control, unlike ON/OFF valves, which are limited to open or closed states. This range allows for fine adjustments, enhancing fluid control in dynamic systems. |

| Can proportional valves be used in high-pressure systems? | Yes, many are designed to withstand high pressure, but it's essential to verify the specific pressure rating of the valve. Selecting a valve with the appropriate rating ensures safety and performance under operational conditions. |

| Are proportional valves energy efficient? | Yes, they conserve energy by allowing precise control, which reduces wear and tear and minimizes mechanical stress on system components. This efficiency contributes to overall lower operational costs and enhances system sustainability. |

| How do proportional valves enhance process control in manufacturing? | By regulating flow rates with high precision, proportional valves enable manufacturers to maintain optimal conditions for production processes, thereby improving quality and consistency of the end products. |

| What factors should be considered when integrating proportional valves into existing systems? | Factors such as compatibility with existing components, required control interfaces, and addressing system responsiveness must be considered to ensure seamless integration and optimal performance. |

Proportional valves have become a staple in modern engineering due to their precision, efficiency, and broad application scope. As technology advances, these valves are expected to evolve further, offering even greater control capabilities and integration into cutting-edge automated systems. Future developments may lead to enhanced features such as advanced diagnostics, improved connectivity for IoT applications, and increased energy efficiency. The increased complexity of systems in industries like smart manufacturing and autonomous vehicles further solidifies the need for sophisticated control solutions such as proportional valves. Their evolution will play a critical role in the ongoing trend towards automation and smart systems, making them an integral component in the quest for higher efficiency and performance in fluid control systems.

Moreover, as industries continue to strive for greater sustainability, the role of proportional valves in reducing energy consumption and minimizing waste will be more critical than ever. Educational and technical resources will also need to keep pace, ensuring that engineers and system designers are equipped with the knowledge to implement these advanced solutions effectively. Overall, the future looks promising for proportional valves as they continue to meet the growing demands of a rapidly changing technological landscape.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!