Delve into the world of proportional valves, essential components in fluid power systems that enable precise control of flow and pressure. These valves are critical in various sectors, including manufacturing, automotive, and robotics, facilitating efficient and accurate operations by modulating outputs based on control signals. This article explores their function, importance, and implementation in modern industries.

Proportional valves are pivotal components in modern fluid control systems. Unlike conventional on/off valves, they provide variable output by modulating flow or pressure, hence allowing for precise control. This capability is vital across industries such as manufacturing, automotive, and robotics, where accuracy and efficiency are paramount. Proportional valves are often incorporated into hydraulic and pneumatic systems, which facilitate a wide range of motions and processes that require fine-tuning to meet specific requirements. Their innovative design and advanced functionalities help drive technological advancements in automation and control, contributing significantly to the industry's evolution.

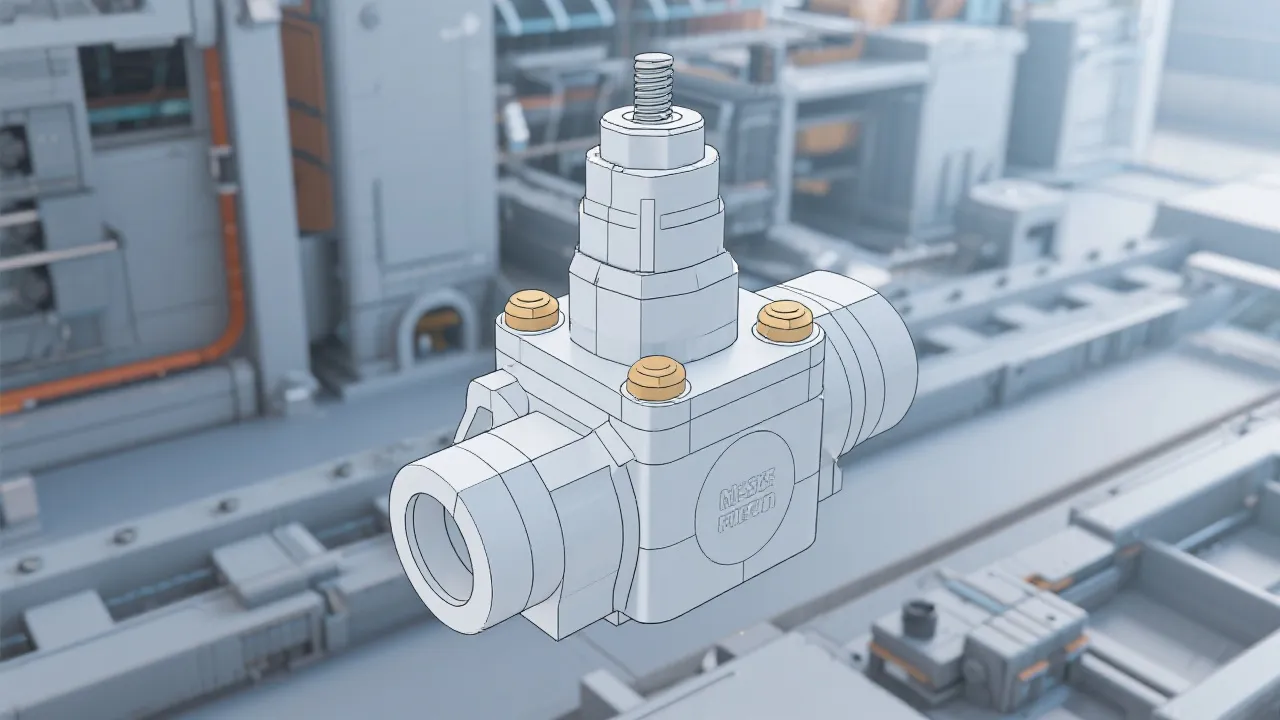

At their core, proportional valves work by adjusting the hydraulic or pneumatic flow in response to varying input signals. These inputs, which are often electronic, can vary the degree to which a valve is opened, allowing for fine-tuned adjustments in pressure and flow rate. This dynamic operation is facilitated by solenoids, which convert electrical signals into mechanical movement. Typically, a proportional valve consists of several key components, including the actuator, sensing elements, and control circuitry which all function collaboratively to achieve the desired flow characteristics.

Modern proportional valves are equipped with advanced technologies such as servo control, digital electronics, and microcontrollers, enhancing their functionalities. For example, many proportional valves utilize feedback systems to monitor the actual flow or pressure and adjust accordingly to meet the set parameters. This closed-loop control method ensures not only accuracy in valve operations but also enhances the overall performance and reliability of the hydraulic or pneumatic systems they are applied in.

Furthermore, these valves can be classified into various types based on their configuration and the method of actuation. Common types include proportional throttling valves, proportional pressure relief valves, and proportional flow control valves. Each type serves unique applications and operational requirements, allowing engineers and designers to select the most suited valve for their applications.

The versatility of proportional valves makes them well-suited for numerous applications. In the automotive industry, they play a crucial role in managing fuel injection systems. By precisely controlling the fuel flow based on engine demands and operating conditions, proportional valves can enhance fuel efficiency and reduce emissions significantly. This aspect is particularly relevant as manufacturers continue to seek methods to meet increasingly stringent environmental regulations and consumer expectations regarding sustainability.

In manufacturing, they regulate hydraulic presses and milling machines for optimal performance. Proportional valves help maintain consistent pressure and flow during machining processes, thereby improving the quality of finished products and reducing operational waste. Additionally, these valves are commonly used in automated assembly lines and material handling systems, where precise movement and positioning are essential for achieving optimal production rates.

Their precision control is also invaluable in robotics, ensuring smooth and accurate movements. Proportional valves enable robots to perform delicate tasks requiring exact force and speed, a vital aspect in applications such as surgical robots or high-precision assembly operations. Moreover, as industries become increasingly focused on automation, the role of proportional valves in robotics will only expand, paving the way for more sophisticated robotic systems capable of executing more complex tasks.

In the aerospace sector, proportional valves are employed in flight control systems and landing gear operations. Their ability to provide precise modulation of fluid flow helps ensure the safe and reliable operation of critical aircraft systems. This application highlights the importance of proportional valves in high-stakes environments where safety and performance are paramount.

While beneficial, the use of proportional valves comes with challenges. They require sophisticated control systems and often involve higher initial costs compared to traditional valves. This complexity necessitates a well-thought-out implementation strategy, as improper integration can lead to inefficiencies or system failures. Maintenance and tuning demand technical expertise to ensure they operate efficiently and accurately, which can sometimes be a barrier in industries that lack the requisite technical skill sets.

Furthermore, proportional valves are often affected by environmental factors such as temperature and fluid viscosity, which can influence their performance over time. As such, understanding the operating conditions and the properties of the fluids used is critical in selecting the right proportional valve for a specific application.

The incorporation of proportional valves into existing systems may also require modifications to other components, such as control systems and instrumentation, necessitating additional investment. Engineers must take the time to conduct thorough feasibility studies and system assessments to gauge the overall cost-benefit ratio of adopting proportional technology.

Recent advancements in smart technology and IoT integration are transforming the capabilities of proportional valves. Industry experts foresee increased adaptation of intelligent systems that self-adjust based on real-time data, further enhancing precision and efficiency in operations. The trend toward predictive maintenance, driven by data analytics and machine learning, indicates an evolving approach to fluid control that can preemptively address potential issues before they escalate into problems.

As the industry moves forward, we are likely to see a greater emphasis on integrating proportional valves with digital controls, allowing for more sophisticated operation and monitoring. This integration will enhance the flexibility and adaptability of fluid control systems, enabling them to respond dynamically to varying operational conditions and demands.

Moreover, the rise of Industry 4.0—characterized by automated processes and interconnected systems—points towards a more significant role for proportional valves within this framework. Their ability to provide precise control in real time aligns perfectly with the operational needs of automated production environments where efficiency and adaptability are crucial.

Another trend worth noting is the growing focus on sustainability within the industry. As industries push for greener solutions, the energy efficiency that proportional valves offer will be seen as a critical advantage. Increased adoption of renewable energy sources and the need for more efficient machinery mean that proportional valves could become a staple in eco-friendly manufacturing practices.

Lastly, advances in materials science and manufacturing techniques may lead to the development of new types of proportional valves that offer enhanced durability, reliability, and performance under extreme conditions, further broadening their applicability across industries.

| Industry | Application | Benefits |

|---|---|---|

| Automotive | Fuel injection systems | Improved fuel efficiency and emissions control |

| Manufacturing | Hydraulic presses | Maximized productivity and quality control |

| Robotics | Movement control | Smooth and precise operation |

| Aerospace | Flight control systems | Reliable and precise motion for safety |

| Marine | Steering and trim systems | Improved maneuverability and efficiency |

In conclusion, proportional valves are integral to the efficiency and precision of various industrial systems. Their ability to finely regulate flow and pressure tailors them to applications demanding exact control. Despite the need for advanced systems and knowledge, their benefits—including energy efficiency and improved system safety—make them a valuable asset in modern technology. As industries face increasing pressure to optimize performance while reducing their environmental footprint, proportional valves will play an essential role in achieving these goals. Their continued evolution through technological advancements will ensure they remain a staple in fluid control, driving innovations across multiple sectors.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!