Proportional valves are critical components in modern machinery, enabling precise control of fluid flow and pressure. These innovative devices are essential for maintaining the efficiency and functionality of systems across various industries, from manufacturing to aerospace. This article delves into the significance of proportional valves, their operational architecture, and the industries they revolutionize, offering insights for engineers and technicians alike.

Proportional valves are integral components used to manage the flow and pressure of various fluids in industrial applications. Unlike traditional on-off valves, proportional valves allow for variable control, enabling fine-tuning of system performance to exact specifications. This capability is crucial in industries where precision and efficiency are paramount, such as in manufacturing, aerospace, and automotive sectors. By allowing for incremental adjustments, these valves improve system responsiveness and enhance overall productivity.

Understanding how these valves function and the benefits they offer requires an exploration into their mechanics, applications, and the technology that supports their operation. As industries continue to embrace automation and sophisticated control mechanisms, the role of proportional valves becomes more pronounced. Their ability to adapt to varying conditions and requirements sets them apart from traditional valve solutions, making them essential tools in modern engineering.

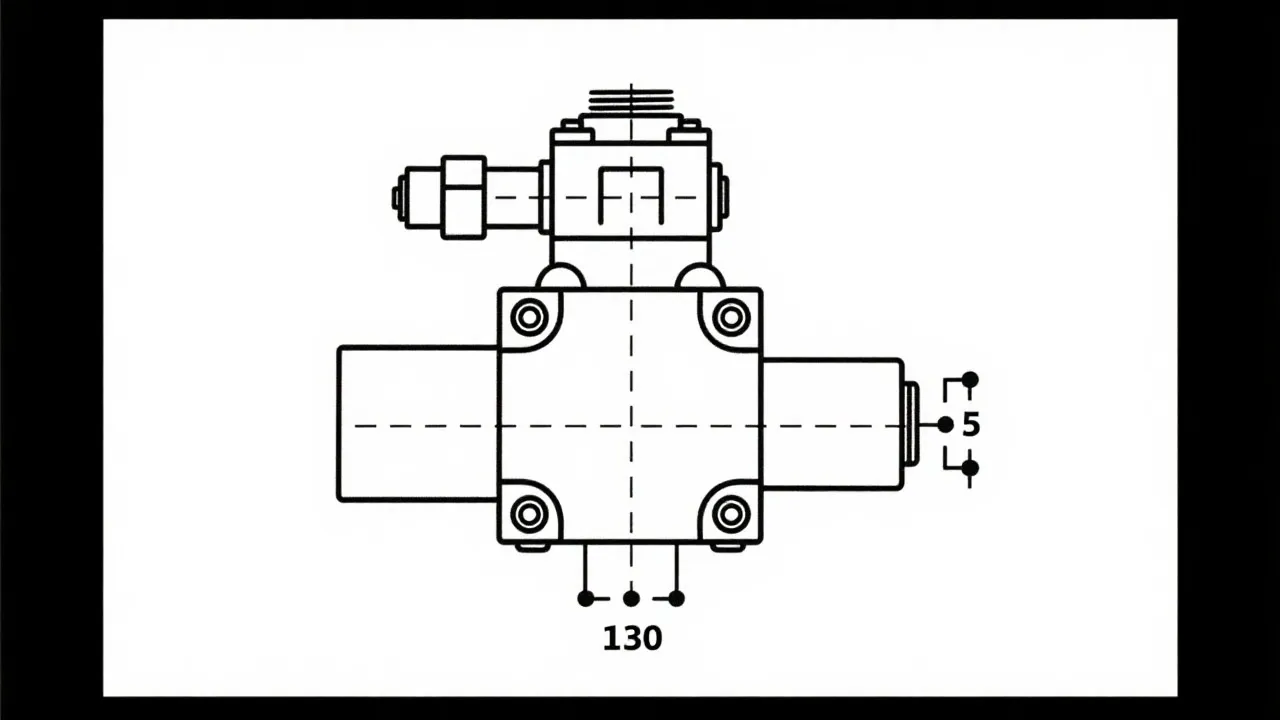

At the heart of a proportional valve’s functionality is the ability to adjust the output flow rate and pressure in proportion to the input signal. This is achieved through the use of solenoids or piezoelectric elements that actuate the valve spool or poppet, adjusting the fluid path. The seamless integration of electronics and mechanical components allows for precise control over the movement and configuration of the valve internals, providing high-resolution adjustments to the system they are embedded within. Proportional valves typically employ a feedback system that ensures the desired flow rate or pressure is maintained even with varying loads.

Proportional valves are controlled via electric signals, often in the form of voltage or current changes. These changes correspond to small, incremental changes in valve position and thus fluid flow. This electronic interface makes them highly adaptable to automated control systems and remote operations, creating a bridge between mechanical operations and digital oversight.

Additionally, these valves may utilize two types of control technologies: closed-loop and open-loop systems. Closed-loop systems involve feedback mechanisms that monitor the output and adjust the input accordingly, ensuring accurate adherence to desired parameters. Open-loop systems lack such feedback, making them simpler but potentially less precise. The choice between these two systems often depends on the specific requirements of the application, including desired accuracy, speed of response, and complexity of the control system.

The utility of proportional valves extends across diverse sectors, showcasing their versatility and vital role in modern industrial processes:

To better understand the operational parameters and technological variants of proportional valves, consider the following specifications:

| Specification | Details |

|---|---|

| Control Type | Electric (voltage/current based) |

| Response Time | Typically fast in response, vital for applications requiring swift adjustments. This rapid response is crucial in dynamic systems where conditions can change rapidly, necessitating immediate adjustments to maintain optimal performance. |

| Material Composition | Often constructed from durable metals such as stainless steel to withstand high pressures and temperatures. Advanced materials may also incorporate polymer composites, which can offer lighter weight and resistance to corrosion, extending the service life of the valves. |

| Flow Rates | Variable, depends on the specific model and intended application. Flow rates can range from very low, precise flows for specialized applications to high-capacity flows for industrial uses, ensuring there's a proportional valve suitable for nearly every need. |

Furthermore, the configuration of proportional valves can be either direct or pilot-operated. Direct-acting proportional valves provide immediate response and are suitable for low-flow applications. In contrast, pilot-operated proportional valves utilize a secondary pilot valve to control a larger flow, making them ideal for high-flow applications while maintaining control precision.

Innovative designs have led to the development of proportional valves that incorporate features such as integrated sensors and advanced control algorithms. These features enhance diagnostics, allowing for real-time monitoring of performance and health status, which aids in predictive maintenance practices. As industries increasingly depend on automation, such innovations position proportional valves as foundational components of smart manufacturing systems.

Selecting an appropriate proportional valve requires careful consideration of several factors tailored to the specific application and operational environment:

Consulting with suppliers and manufacturers can provide valuable insights, including access to simulation tools or predictive analytics that can help guide the selection process. It is advisable to consider potential future requirements and scalability, as investing in a slightly more advanced or flexible valve could pay off as operational demands evolve.

As technology advances, the role of proportional valves continues to expand. The integration of digital control interfaces and data analytics promises to enhance their functionality significantly. With the rise of IoT (Internet of Things) and smart systems, proportional valves are evolving to include self-diagnostic features and adaptive control mechanisms that improve their responsiveness and integration into broader automated systems.

Moreover, developments in materials science are contributing to more durable and efficient valve designs, decreasing maintenance needs and extending operational lifespans. This evolution aligns with industry demands for sustainable and energy-efficient solutions, positioning proportional valves as a linchpin in the future of engineering and technology.

Additionally, the push towards Industry 4.0—characterized by intelligent production methods and smart factories—highlights the necessity for valves that can communicate effectively with other systems. Proportional valves that incorporate artificial intelligence and machine learning capabilities could be trained to optimize performance based on operational data, learning from usage patterns to improve efficacy over time.

Furthermore, as companies aim to minimize their environmental footprints, advancements in valve design are likely to focus on enhanced energy efficiency and reduced waste generation. This shift will encourage the use of materials and technologies that contribute to overall sustainability efforts, reinforcing the importance of proportional valves within modern industrial ecosystems.

As industries look forward, the synergy between proportional valves and emerging technologies promises to drive innovation and unlock new possibilities across multiple sectors, creating smarter systems that enhance productivity while safeguarding environmental health.

In conclusion, proportional valves are not merely components but are pivotal in driving efficiencies and innovations in various industrial sectors. Their ability to precisely control fluid dynamics makes them indispensable in modern machinery and systems. As technology continues to advance, the future of proportional valves looks promising, with opportunities for further integration into smart systems that will revolutionize industrial operations.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!