Burkert Proportional Valves are pivotal in facilitating precision flow control in various industrial applications. These sophisticated devices leverage advanced technology to regulate the flow of liquids and gases with unparalleled accuracy, adapting to the ever-evolving demands of modern industries. This comprehensive guide explores their functionality, applications, and the significant advantages they offer to industries worldwide.

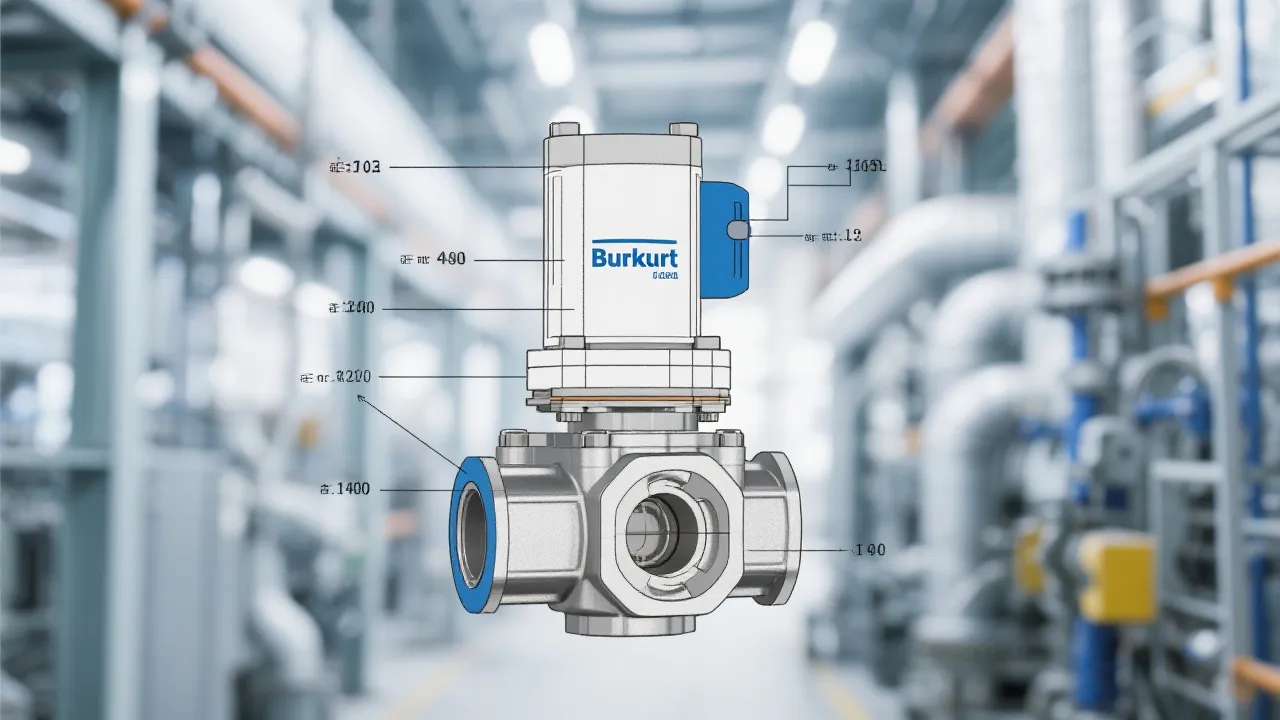

At the core of precise fluid control in today's sophisticated industrial landscape is the Burkert Proportional Valve. This device stands out in its ability to modulate the flow of gases and liquids with precision, which is essential for maintaining optimal operating conditions in a variety of industrial processes. Manufactured by the renowned company Burkert, these valves blend innovation with efficiency, reflecting the company's commitment to advancing flow technology.

As industries increasingly rely on automation and the implementation of Industry 4.0 principles, the demand for components that ensure performance efficiency and operational flexibility has surged. Burkert Proportional Valves not only meet these demands but also set a standard in terms of quality and reliability. Their capacity to react dynamically to changing process conditions makes them a vital component in both new installations and upgrades to existing systems across various sectors.

Proportional valves are dynamic mechanisms that adjust flow rates continuously based on input signals. This capability is beneficial in processes where conditions fluctuate, and maintaining equilibrium is crucial. Unlike traditional valves that operate in binary (open/close) modes, proportional valves allow for variable positioning, leading to nuanced control and reduced energy consumption. The Burkert Proportional Valve, through its precise calibration and design, ensures reliability even under high-demand conditions.

The working principle of a Burkert Proportional Valve involves a solenoid and a feedback mechanism that constantly measures and adjusts the valve position based on the real-time requirements of the system. As a result, these valves can handle varying pressures and flow rates while maintaining accuracy. The integration of advanced sensors and controllers enables a level of responsiveness in process management that traditional valves cannot achieve. This responsiveness is particularly important in high-speed production environments where even slight deviations can lead to significant inefficiencies or product defects.

The Burkert Proportional Valve finds applications in numerous sectors. In the chemical industry, it regulates reactions by controlling the flow of reactive agents precisely. It allows operators to fine-tune the ingredient mix for optimal reaction conditions, thus minimizing waste and maximizing yield. Such precision in flow control is critical to maintaining safety and compliance with environmental regulations.

In the food and beverage industry, it ensures hygienic and repetitive processes by providing exact flow control. The ability to maintain consistent flow rates during bottling or drafting processes helps to preserve product integrity and quality while facilitating compliance with strict industry standards for sanitation. The hygienic design of many Burkert valves minimizes the risk of contamination, making them ideal for this sector.

Furthermore, in the medical sector, these valves are critical in devices requiring precise gas flow, such as anesthesia machines. Here, the ability to deliver accurate dosages is not just a matter of efficiency but a vital aspect of patient safety. In laboratory settings, Burkert Proportional Valves play an essential role in applications ranging from sample handling to process control, showcasing their versatility and importance across a myriad of applications.

Adopting Burkert Proportional Valves offers multiple advantages. Firstly, they enhance process control, thereby increasing efficiency and reducing wastage. Their design minimizes wear and tear, leading to longer service life. Additionally, these valves are equipped with intelligent diagnostics for maintenance, further contributing to operational efficiency by preemptively addressing potential issues.

These diagnostic features allow operators to monitor valve performance in real-time, enabling proactive maintenance strategies that prevent costly downtime. By integrating Condition-Based Maintenance (CBM) practices, companies can optimize maintenance schedules and allocate resources more effectively. This feature not only saves costs but also extends the lifecycle of the equipment by reducing the likelihood of unexpected failures.

Moreover, the scalability of Burkert Proportional Valves allows businesses to adapt to fluctuating production demands. Whether increasing output during peak seasons or scaling down during lighter periods, the flexibility provided by these valves ensures that systems remain efficient and responsive. This adaptability is particularly valuable in industries characterized by rapid change and the need for rapid responses to market trends.

| Industry | Application |

|---|---|

| Chemical | Precise control of reactive agent flow in reactions. |

| Food & Beverage | Maintaining hygiene with repeatable flow processes. |

| Medical | Accurate gas flow in anesthesia equipment. |

| Pharmaceutical | Exact dosing and fluid handling in drug production. |

| Water Treatment | Regulating water flows for treatment processes. |

One of the standout features of Burkert Proportional Valves is their adaptability to different systems. They can be integrated with various control systems, offering companies the flexibility to upgrade without overhauling their existing infrastructure. Customization options allow these valves to meet specific requirements, making them suitable for unique industrial challenges.

Manufacturers can select from a variety of sizes, materials, and control mechanisms, ensuring a perfect match for any application. The ability to customize the valve's response times and control algorithms enables users to optimize the performance characteristics precisely to their needs. For instance, adjustments can be made to the scaling of control inputs to better suit the volume flow characteristics of a specific application.

Additionally, the modular design of Burkert Proportional Valves allows for easy maintenance and reconfiguration without the need for specialized tools or extensive retraining of the staff. This ease of maintenance contributes significantly to reducing operational downtime, thereby improving overall productivity. The integration of digital interfaces ensures that these valves can be paired with advanced monitoring solutions, remotely adjusting processes while providing real-time feedback to operators.

Q: How do Burkert Proportional Valves improve energy efficiency? A: By providing precise flow control, these valves reduce unnecessary energy consumption, which is common when using conventional on/off valves.

Q: Are there maintenance requirements for Burkert Proportional Valves? A: Yes, regular maintenance is recommended. However, these valves offer built-in diagnostic capabilities that simplify and reduce maintenance efforts.

Q: Can these valves be used in hazardous environments? A: Burkert designs valves with materials and configurations suitable for various environments, including those with hazardous conditions, ensuring both safety and performance.

Q: What types of feedback mechanisms do Burkert Proportional Valves utilize? A: Many Burkert Proportional Valves leverage either integrated or external feedback devices, such as position sensors, to maintain optimal valve positioning and flow accuracy.

Q: Can Burkert Proportional Valves be used in high-pressure applications? A: Yes, Burkert offers models designed for high-pressure environments, ensuring reliable performance while complying with relevant safety standards.

Q: What materials are used in Burkert Proportional Valves? A: The valves are available in a range of materials, including stainless steel and various plastics, tailored to meet specific industry requirements and corrosion resistance.

Burkert Proportional Valves are at the forefront of modern industrial flow control solutions. With their precision, adaptability, and robustness, they are integral to the functionality of critical processes in various industries. By investing in these valves, companies are poised to enhance their operational efficiency while maintaining flexibility in their control systems. As industries continue to evolve, the role of such advanced technological solutions will become increasingly indispensable.

In an environment where every efficiency gain translates into significant financial savings, the ability of Burkert Proportional Valves to enhance control and reduce waste can be a decisive factor. Companies implementing these solutions not only optimize their fluid control processes but also position themselves as leaders in their respective markets. By committing to the continuous improvement and innovation embodied in the Burkert Proportional Valve design, industries pave the way for sustainable practices that safeguard operational integrity while fostering environmental stewardship.

Ultimately, the future of industrial flow control will be shaped by advancements like those seen in Burkert Proportional Valves. Their ongoing development will continue to reflect trends towards automation, precision engineering, and process optimization—qualities essential for thriving in a competitive global market. As we anticipate future challenges and opportunities in industrial operations, embracing such cutting-edge technologies becomes not just beneficial but essential for success.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!