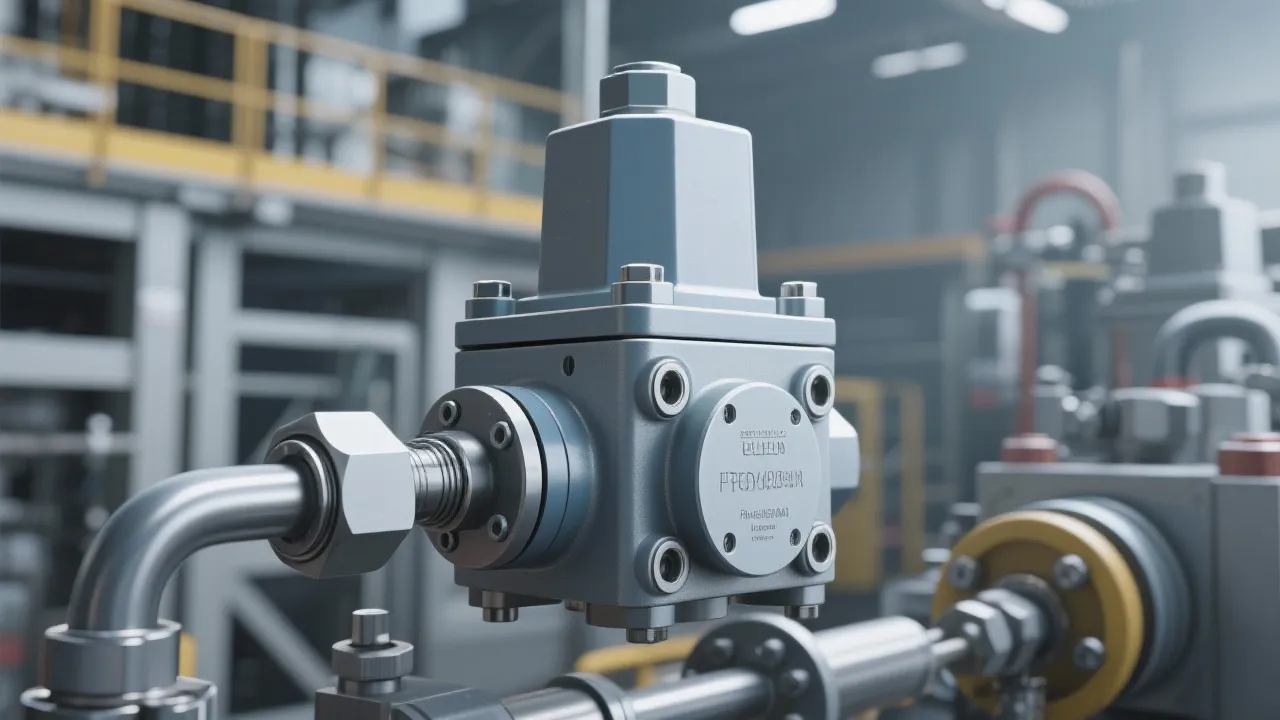

Proportional valves play a critical role in controlling fluid flow within various industries. These components offer precise regulation based on electronic signals, impacting sectors like manufacturing and automation. By adjusting the flow and pressure of fluids, they ensure optimal operational efficiency and safety in complex systems. Let's explore the intricacies and applications of proportional valves across different sectors.

In the realm of fluid power control, proportional valves stand out as pivotal elements that enable precise modulation of flow and pressure. Unlike traditional on/off valves, which operate in a binary manner, proportional valves allow for granular adjustments that improve process efficiency and system responsiveness. These advanced components convert electronic signals into mechanical motion, offering a seamless blend of hydraulic or pneumatic power with electronic control. The sophisticated nature of proportional valves significantly enhances the ability to control fluid systems, making them indispensable in various industrial applications.

Proportional valves operate by variably adjusting the opening of the valve, which in turn controls the flow rate and pressure of the fluid passing through it. This functionality is primarily achieved through a spool positioned by a solenoid that receives proportional electrical signals. The resultant motion of the spool is proportional to the input signal, allowing for a spectrum of flow rates, from maximum to zero. The precision in this control allows for smoother operation of machinery and more efficient processes, which is essential in applications where timing and correct pressure levels are critical.

In a typical proportional valve setup, the solenoid may convert a voltage input signal into corresponding mechanical movement. This conversion process occurs through electromagnetic principles. When electrical current flows through the solenoid, it creates a magnetic field that pulls or pushes the spool to a designated position. The exact position of the spool directly correlates with the received control signal, thereby providing real-time adjustments to fluid dynamics in the system. This feature means that operators can fine-tune processes with remarkable accuracy, leading to increased productivity and reduced operational costs.

Proportional valves are quintessential in industries such as manufacturing, automotive, aerospace, and energy. One significant example in the manufacturing sector is the application of proportional valves in CNC (Computer Numerical Control) machining systems. Here, precision is paramount, as even the slightest deviation can result in product defects. Proportional valves help maintain consistent pressure and flow rates during the machining process, ensuring that every operation is executed correctly and efficiently.

In automotive applications, proportional valves play a crucial role in fuel injection systems, particularly in modern vehicles where fuel efficiency has become a focus. These valves modulate the flow of fuel into the engine based on complex algorithms that take into account speed, load, and other conditions to optimize performance and reduce emissions. This adaptive control ensures that vehicles operate at peak efficiency across various conditions, enhancing both performance and environmental sustainability.

The aerospace industry also benefits significantly from proportional valves, particularly when it comes to the management of hydraulic systems essential for the operation of aircraft controls and landing gear. The reliability and precision of these valves are critical for safety and performance in flight. Here, proportional valves ensure that movements are smooth and predictable, which is vital for control during takeoff, maneuvers, and landings. The high stakes associated with aerospace rely heavily on these components for safe and effective operation.

Additionally, the energy sector leverages proportional valves for diverse applications, including hydraulic control in wind turbines and oil drilling. In wind turbines, for example, these valves can adjust the blade pitch to optimize power generation based on wind conditions, thereby enhancing energy yield. In oil and gas extraction, proportional valves help control drilling fluid pressure and flow, critical for safe and efficient drilling operations.

The versatility of proportional valves allows manufacturers to optimize not only the performance of machinery and equipment but also the efficiency and sustainability of entire processes. This adaptability is a significant advantage in today's fast-paced industrial environments, where the demand for flexibility and innovation is ever-increasing.

The selection of proportional valves depends on numerous factors, including the type of fluid, operating pressure, required precision, and system compatibility. Understanding the different types of proportional valves is essential for making informed decisions about their application. There are two primary categories of proportional valves: direct-acting and pilot-operated. Each type offers distinct features suited to different applications.

Direct-acting proportional valves typically feature a simple construction and yield an immediate response. They are ideally suited for small systems that require quick and accurate adjustments. Since they operate directly on the fluid, these valves are often used in low-flow applications where rapid response times are critical.

On the other hand, pilot-operated proportional valves are designed to handle larger flows and provide greater precision in flow control. They work by using a smaller pilot valve to control a larger main valve, which is beneficial in industrial automation and large-scale systems. These valves can modulate high flow rates while maintaining high levels of accuracy, making them indispensable in applications where significant amounts of fluid need to be controlled.

| Type | Features | Applications |

|---|---|---|

| Direct-Acting | Simple construction, immediate response, suitable for low-flow systems. | Ideal for small systems requiring quick response, such as laboratory settings and compact machinery. |

| Pilot-Operated | Handles larger flows, more precise control, requires more complex installation. | Commonly used in industrial automation and large-scale systems, such as manufacturing plants and hydraulic machinery. |

Other factors influencing the selection of proportional valves include ambient temperature, pressure range, and the nature of the fluid (e.g., corrosive, viscous). Additionally, considerations regarding the integration with existing controls or the need for compatibility with various electronic control systems can determine the best choice for a specific application.

Recent advancements in proportional valve technology have focused on enhancing precision, energy efficiency, and overall performance. Smart proportional valves now incorporate microprocessors that manage real-time adjustments and diagnostics. The integration of sensors in these valves allows for enhanced monitoring capabilities, enabling predictive maintenance and reduced downtime in industrial processes.

The move towards digitization in industrial environments has also seen the rise of IoT (Internet of Things) applications where proportional valves can be monitored and controlled remotely. This capability means that operators can manage their fluid systems from virtually anywhere, allowing for greater flexibility and responsiveness. Real-time data collection empowers companies to gather insights that can be used for further optimization, driving continuous improvement processes.

Moreover, advancements in materials and manufacturing processes have led to the development of more robust and reliable proportional valves. Innovations such as 3D printing have emerged, allowing for the rapid prototyping and production of valve components with intricate designs that enhance functionality. Additionally, the shift towards sustainable practices has prompted manufacturers to employ eco-friendly materials and designs in their products, reflecting a growing commitment to sustainability.

In high-performance settings, adaptive control algorithms have been developed that allow proportional valves to automatically adjust based on real-time feedback from the system they are managing. Such advancements mean that these valves can learn and adapt, ensuring optimal performance under varying conditions without manual intervention. This sophistication is a testament to the significant strides being made in the field of fluid control technology.

While proportional valves offer numerous benefits, they also come with challenges that need to be addressed. One of the principal concerns is the potential for malfunctions due to contamination or wear. The precision components within proportional valves can be adversely affected by foreign particles, leading to faulty operation and compromised performance. Thus, implementing effective filtration systems and regular maintenance checks is paramount to ensure valve integrity and reliable operation.

Another challenge associated with proportional valves is the need for precise calibration. To function optimally, these valves must be accurately tuned to the specific requirements of the application. Calibration should be conducted in accordance with the system’s operational parameters and environment, which can often necessitate specialized knowledge and equipment. Regular recalibration may be necessary, especially in dynamic environments where conditions frequently change.

Moreover, the complexity of proportional valve systems can pose installation challenges. These valves often require careful setup to ensure that they communicate correctly with the control systems in place. Insufficient or improper installation can lead to inefficiencies or failures, prompting the need for skilled technicians familiar with fluid dynamics and electronics.

Lastly, although proportional valves can greatly enhance energy efficiency, their initial costs may be higher compared to conventional valves. Companies must weigh the long-term savings associated with energy efficiency, reduced maintenance, and improved system performance against initial investments to make informed decision-making about incorporating proportional valves into their operations.

Proportional valves are vital components that significantly contribute to the efficiency and precision of modern industrial systems. By allowing electronic adjustment to fluid dynamics, they facilitate industries in achieving optimal performance and fostering innovation. Understanding their role and selecting the right type for a given application can yield substantial benefits in operational efficiency and cost reduction.

The growing complexity of modern processing systems necessitates the advanced capabilities offered by proportional valves, making them crucial to the future of fluid control in various sectors. As industries continue to evolve and demand more from their equipment, the importance of embracing proportional valves as integral parts of fluid power systems cannot be overstated.

Q: What industries benefit most from proportional valves?

A: Manufacturing, automotive, aerospace, and energy sectors are primary beneficiaries of proportional valves due to their need for precise fluid control.

Q: How do proportional valves enhance energy efficiency?

A: By allowing precise control over fluid flow and pressure, these valves reduce wastage and optimize system performance, conserving energy.

Q: What maintenance is required for proportional valves?

A: Regular inspections and cleaning to prevent contamination, along with calibration checks, are necessary to maintain efficiency and functionality.

Q: How does one select the right proportional valve?

A: When selecting a proportional valve, consider factors such as fluid type, operating pressure, required precision, and compatibility with existing systems, along with the specific application needs.

Q: What technological advancements are being made in proportional valves?

A: Recent innovations include the integration of microprocessors for real-time control, IoT connectivity for monitoring, and the use of new materials for enhanced durability and efficiency.

Q: What are the primary challenges associated with using proportional valves?

A: Challenges include potential malfunctions due to contamination, the need for precise calibration, installation complexity, and higher initial costs compared to conventional valves.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!