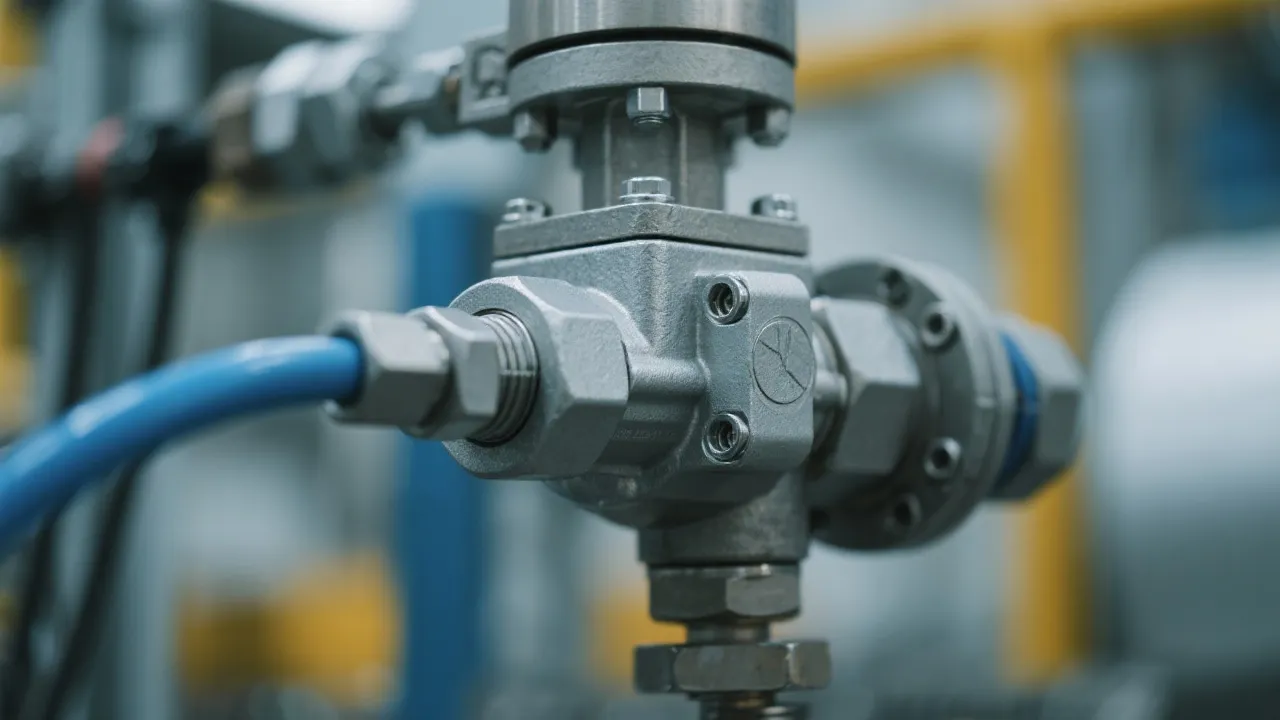

This comprehensive guide explores the essential role of proportional valves in industrial applications. Proportional valves are crucial components used to control air or fluid flow rate and pressure in various systems. Their precision and efficiency make them indispensable in sectors like manufacturing, automotive, and energy, where accurate control of flow variables is necessary for optimal performance.

In the realm of industrial applications, proportional valves are indispensable devices that ensure precision in controlling flow rates and pressures. These valves are especially vital in applications requiring precise modulation of fluid power, offering benefits such as improved machine performance, increased efficiency, and reduced energy consumption. The importance of these valves is evident in various sectors that rely heavily on accurate control mechanisms, all of which contribute to optimized workflows and reduced operational costs. In this article, we will delve deeper into the workings, advantages, applications, and future developments of proportional valves, demonstrating their essential place in modern industry.

Proportional valves are advanced control valves that modulate fluid or air flow in a system with high accuracy. Unlike traditional on/off solenoid valves, proportional valves adjust the flow rate incrementally, allowing for smooth and controlled transitions. This capability is particularly important in maintaining stable system operations and preventing wear and tear due to abrupt changes in flow or pressure. By providing variable control, these valves allow machines to adapt to varying operational requirements, making them a critical element in sophisticated field applications where precision is paramount.

The neural network of a proportional valve typically consists of a spool within a cylinder, which responds to electrical input signals that dictate its position. Depending on the valve design, this can involve either linear or rotary motion to achieve the desired result. As the spool shifts, it either opens or restricts the flow path, thus modulating the fluid's passage in accordance with the predetermined specifications, offering a dramatic improvement in control capabilities over conventional valve types.

These valves use electrical signals to adjust the position of the valve spool, thus controlling the flow rate. The signal is typically proportional to the desired flow rate or pressure, hence the name 'proportional valves.' By continuously adjusting the spool position, these valves ensure precise control, making them suitable for various applications ranging from robotics to automotive systems. The control signal can originate from various sources, including controllers that analyze system data and determine the appropriate adjustments necessary for optimal performance.

In practical terms, the functionality of proportional valves can be broken down into several core components. The input, usually a variable voltage or current signal, is processed by an electronic control unit which determines the output signal sent to the valve's actuator. As a response to these control signals, the actuator then moves the valve spool to the required position, which in turn determines the flow rate or pressure in the system. This close loop system allows for very highly adaptive variations in fluid delivery, which means machines can work at their peak efficiencies while also accommodating different operational scenarios as they arise.

Proportional valves find use in multiple sectors:

| Aspect | Proportional Valves | Traditional Valves |

|---|---|---|

| Control Precision | High | Low |

| Energy Efficiency | Better | Less Efficient |

| Response Time | Quick | Variable |

| Applications | Wide Range | Limited |

| Installation Complexity | Moderate | Relatively Simple |

| Cost | Higher Initial Investment | Lower Initial Cost |

When selecting a proportional valve, consider factors such as the system pressure requirements, flow rate demand, environmental conditions, and the type of fluid involved. Consulting a supplier or manufacturer that specializes in these components can provide insights into the very suitable options for specific industrial needs. It's also essential to evaluate the valve’s compatibility with existing system controls and to consider future scalability—ensuring that the chosen valve can adapt to potential increases in demand or changes in operational requirements.

Additionally, assessing the electrical control types available (e.g., analog vs. digital) and understanding the integration with existing control systems will be key steps in your decision-making process. For applications that involve rapidly changing conditions, look for valves with high responsiveness and low hysteresis to ensure that the system remains stable and efficient.

The installation of proportional valves can sometimes be more complex than that of traditional valves. Proper alignment, orientation, and incorporation into the automation system must be considered, ultimately affecting operational efficiency. Ensuring that the valve is placed in an appropriate position within the circuit can help mitigate flow disturbances that might occur due to improperly installed components. Furthermore, users should ensure that all electrical connections are secure and that the control signals are sufficiently characterized.

Installation also necessitates a thorough understanding of the specific system dynamics. Proportional valves should be integrated into the hydraulic or pneumatic system's design to facilitate predictable and desirable performance. Areas requiring attention include checking for sufficient clearance, avoiding excessive vibration, and ensuring compatibility with surrounding environmental conditions—this could mean anything from temperature ranges to exposure to debris or chemicals.

Maintenance is crucial for ensuring the longevity and reliability of proportional valves. Regular inspection for wear and tear, cleaning to prevent blockages, and ensuring electrical connections are secure are critical maintenance steps. Operators should develop a maintenance schedule based on the valve’s operating conditions and manufacturer recommendations. This proactive approach can significantly minimize unplanned downtimes and enhance operational safety.

Specific maintenance tasks may include:

Inaccurate control signals, environmental constraints, and fluid contamination can pose challenges to their optimal functioning. For instance, noise in the control signal can lead to unstable valve performance, resulting in erratic system behavior. Filters and additional circuitry can help mitigate these issues.

Environmental factors, such as temperature extremes or exposure to corrosive substances, may lead to faster degradation of the valve materials. It's crucial to utilize valves rated for specific environmental conditions and, when required, to implement protective measures such as housing or enclosures to safeguard against external factors.

Fluid quality is another significant element; even micro-particles can lead to malfunctions, reduced performance, and potential system failures. Using high-quality filtration systems in conjunction with regular fluid analysis can help ensure that the operated system remains safe and efficient.

With advancements in technology, proportional valves continue to evolve, becoming integral to the efficiency and efficacy of industrial applications. As industries increasingly emphasize automation and smarter systems, the demand for more advanced control valves is expected to grow. Key developments are likely to include:

As proportional valves continue to develop, they will likely become an even more central aspect of industrial processes. Their precision, efficiency, and adaptability will ensure their role in future industrial advancements remains significant, solidifying their place in the advanced machinery of tomorrow. With ongoing research and innovation, it is evident that proportional valves are not just components of fluid control systems; they are, in fact, vital tools that empower industries to innovate and improve.

The significance of proportional valves in various industrial applications cannot be overstated. As automation becomes more prevalent and industries strive for enhanced efficiency and effectiveness, understanding the workings, advantages, and future developments of proportional valves will be crucial. Investing in these essential components not only leads to improved machine performance but also translates into long-term operational benefits through reduced energy consumption, lower maintenance costs, and enhanced system dependability. As technology continues to advance, the potential for innovation in this area suggests that proportional valves will only grow more essential, further driving efficiencies and advancing industrial capabilities for years to come.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!