Proportional valves are essential components in fluid control systems, allowing precise flow and pressure regulation. These valves help achieve fine-tuned control for applications in various industries, providing efficiency and adaptability in system operations. The significance of proportional valves lies in their ability to adjust to specific needs dynamically, enhancing the overall performance of hydraulic and pneumatic systems.

Proportional valves play a crucial role in modern fluid control systems. Their ability to precisely regulate flow and pressure makes them indispensable across multiple industries, ranging from automotive to industrial automation. Unlike conventional on-off valves, proportional valves offer a variable output that can be finely tuned to meet specific operational requirements, enhancing both efficiency and flexibility in system management. The foundation of proportional valve technology rests on the principle of modulation, where a control signal defines the valve's position and hence its output. The need for precise control in various applications is paramount as it greatly influences the performance and safety of machines and processes, a feature made possible through advancements in proportional valve technology.

In fluid power systems, the primary function of a proportional valve is to modulate flow and pressure proportionally to a control signal. This modulation allows for smoother transitions and finer control over a system’s output. Such precise control is essential in applications where the accuracy of flow and pressure adjustments can impact performance and safety, such as in manufacturing processes, robotics, and aerospace engineering. For instance, in robotic systems, proportional valves control the actuation of robotic arms with high accuracy, enabling complex movements with minimal error. Similarly, in the aerospace industry, proportional valves regulate landing gear systems and flight control surfaces, where micro-adjustments can be critical to performance and safety.

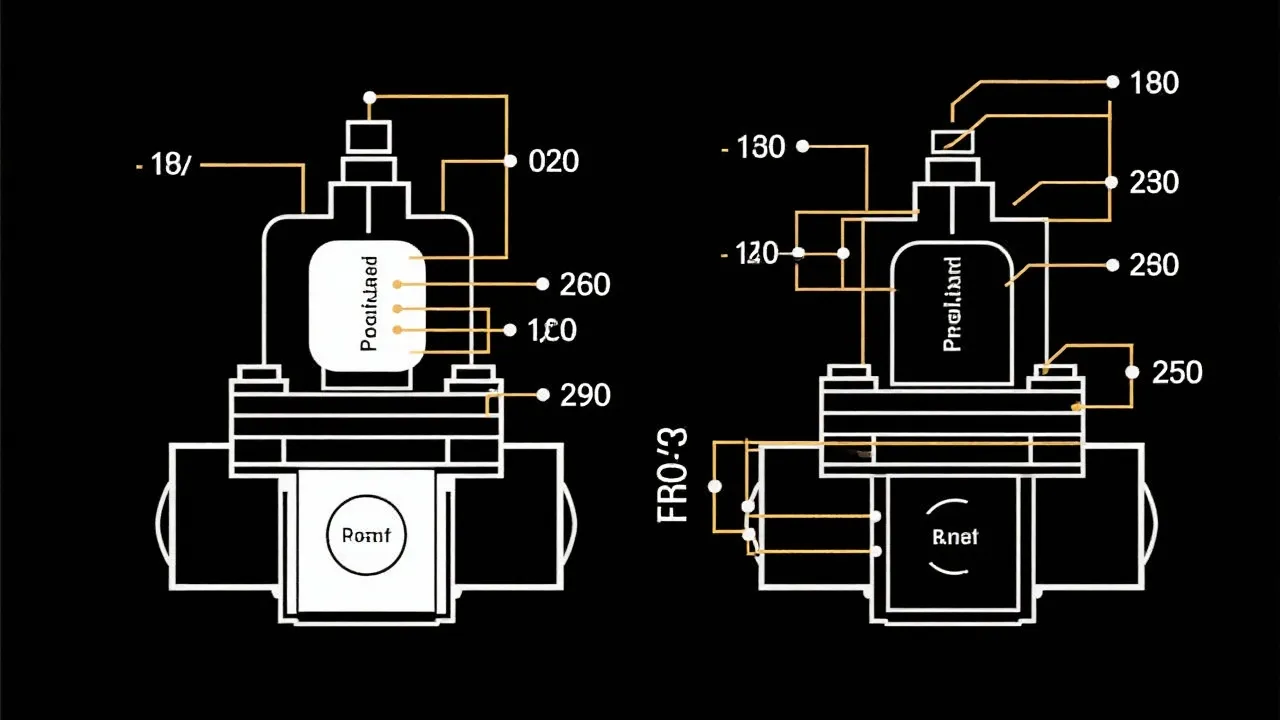

A proportional valve typically consists of a solenoid-operated spool that is governed by a control signal, often an electrical input, which adjusts the position of the spool. This movement regulates the opening size through which the fluid passes, allowing for variable flow rates and directional control. The intricate design of these valves enables them to handle diverse media and operating conditions, making them remarkably versatile. Advanced models incorporate features like feedback sensors, which provide real-time data to optimize valve response and performance further. The integration of such sensors allows for closed-loop control systems, which continuously adjust the valve position to maintain the desired operational parameters, enhancing overall system reliability and efficiency.

One of the very significant advantages of proportional valves is their ability to enhance system efficiency by providing dynamic flow control. They reduce energy consumption by limiting fluid loss and ensuring that the system only uses the necessary pressure and flow. Additionally, these valves offer superior response times and reduced mechanical wear, thanks to their refined control mechanisms. This leads to lower maintenance costs and prolonged service life. Moreover, the adaptability of proportional valves allows for their use in various environmental conditions, be it high-pressure scenarios in industrial settings or precision tasks in sensitive applications such as medical devices or laboratory equipment. By offering precise flow control, proportional valves help improve product quality and consistency, which is essential in sectors like food processing, pharmaceuticals, and electronics manufacturing.

The versatility of proportional valves allows their application across various industries. In the automotive industry, they are crucial for optimizing hydraulic systems in vehicles. For example, in hybrid vehicles, proportional valves help manage the disconnect between the electric motor and the internal combustion engine, ensuring smoother transitions for the driver. Industrial automation relies on these valves for precise control of complex machinery, improving production quality and consistency. Their role in automated assembly lines enhances throughput while minimizing errors. Similarly, in the aerospace sector, proportional valves ensure that hydraulic systems respond accurately to pilot commands, enhancing safety and performance. Beyond these, industries like construction, mining, and renewable energy also leverage proportional valve technology to improve operational efficiency and reduce downtime.

Selecting an appropriate proportional valve involves considering several factors, including the system's specific needs, the nature of the fluid, operating conditions, and desired flow control characteristics. Understanding these aspects aids in ensuring compatibility and reliability, which are paramount for optimal system function. It is also crucial to consider the valve's response time, as delays can lead to performance issues, especially in high-speed applications. Users should evaluate the materials used in valve construction to ensure compatibility with the fluids processed; for instance, corrosive fluids may require valves constructed from specific alloys or treated materials to withstand degradation. Additionally, manufacturers often provide technical specifications and performance data that can guide users in making an informed choice based on their specific requirements.

While proportional valves offer numerous benefits, users may face challenges such as system integration difficulties, signal interference, or response time delays. Overcoming these challenges involves selecting high-quality valves, employing proper calibration procedures, and incorporating advanced control systems to fine-tune performance. For instance, using shielded cables can help mitigate signal interference, ensuring consistent performance in dynamic environments. It is also advisable to conduct thorough testing during the integration phase to identify potential issues early on and adjust system parameters accordingly. Furthermore, regular maintenance and troubleshooting procedures can be important in identifying wear and potential faults in proportional valves, leading to increased longevity and reliability of the system as a whole.

| Valve Type | Functionality | Pros | Cons |

|---|---|---|---|

| Proportional Valve | Variable flow and pressure control | Precise control; energy efficient; adaptable to various applications | Costlier than basic valves; may require more complex control systems |

| On-Off Valve | Binary flow control | Simple design; inexpensive; easy to operate | No variable control; can lead to system shock or pressure surges |

| Servo Valve | High precision flow regulation | Extremely precise; quick response; suitable for critical applications | Complex and maintenance-intensive; higher cost |

Proportional valves represent a key advancement in the control of fluid systems, providing precise, efficient, and adaptable management that benefits a wide spectrum of industries. By understanding their operation, advantages, and applications, businesses can leverage these valves to improve system performance and reduce operational costs. With their capability to offer fine-tuned control, proportional valves will continue to be integral components in modern automated systems. The growth of IoT and smart technology is also likely to enhance the functionality of proportional valves, paving the way for even more advanced applications and efficiencies in the future. As industries continue to evolve and automate, the importance of high-quality fluid control mechanisms such as proportional valves cannot be overstated; they are at the forefront of improving productivity, ensuring safety, and driving innovation across industrial landscapes.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!