The proportional valve lies at the core of advanced fluid control systems, essential for precision in industrial automation and mechanical applications. This article delves into the working principles, applications, and technical nuances of proportional valves, offering insights from an industry expert's perspective on their importance in modern engineering.

In the dynamic field of fluid control engineering, proportional valves have emerged as a pivotal component, offering nuanced control over flow and pressure. Essential for precision-controlling tasks within various industries such as manufacturing, automotive, and aerospace, these valves provide a seamless transition between fully open and closed positions, fine-tuning the output to match the specific demand of the application. Their innovative design allows for a sophisticated interaction between hydraulic systems and electronic controls, delivering an unprecedented level of performance expected in today's high-tech environments.

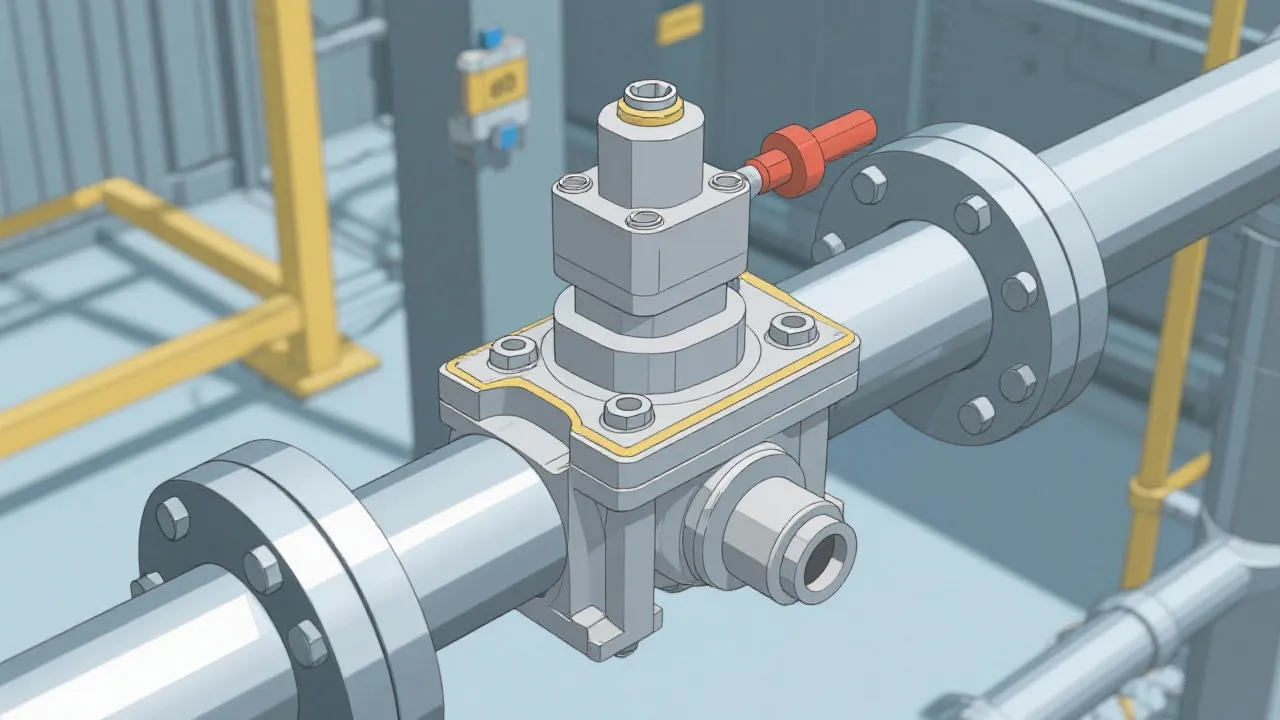

Proportional valves operate using electromagnetic actuation to alter the position of a spool, thereby modulating the flow of fluids. The degree to which the spool moves in response to electrical signals is proportionate, hence the name. This enables the valves to perform with a high degree of precision, making them invaluable in applications requiring intricate flow control. The internal workings of a proportional valve can seem complicated, yet they can be understood by breaking down their components and functionalities.

At the heart of a proportional valve lies its actuator, typically an electric solenoid that uses a magnetic field to produce motion. When an electric current is applied, the solenoid generates a magnetic force that moves the spool within the valve body. Depending on the design, this movement can be linear or rotary, allowing for fine adjustments to be made to the fluid’s path. The resulting change in the spool position adjusts the flow area, thereby altering the flow rate or pressure in a controlled manner. Additional features like feedback sensors can further enhance performance by providing real-time data to ensure operational parameters remain within designated ranges.

Moreover, proportional valves may incorporate advanced technologies such as digital signal processing and microcontrollers to precision-tune operations. These enhancements contribute to their application in advanced manufacturing settings, where processes are increasingly automated and demand greater responsiveness from control systems.

Industries heavily reliant on automation processes have benefitted tremendously from the introduction of proportional valves. For instance, in automotive manufacturing, they regulate hydraulic fluid flow, ensuring accurate movement of machinery for tasks such as stamping, welding, and painting. These applications require not only speed but also the ability to fine-tune the force applied, ensuring high quality and consistency in production.

Similarly, in process control industries, they maintain stringent control over media such as gases and fluids, optimizing operational efficiency and safety. In chemical processing, for example, proportional valves can control the flow of reagents with great precision, allowing for safer reactions and better product quality. Furthermore, in the realm of food and beverage processing, these valves help manage the flow rates of ingredients, thereby maintaining strict compliance with health and safety regulations.

Beyond manufacturing, proportional valves find applications in the aerospace sector, controlling hydraulic systems that influence everything from landing gear to flight control surfaces. Their ability to perform under extreme environmental conditions reinforces their significance in critical applications where reliability is non-negotiable.

| Feature | Benefits |

|---|---|

| Precision Control | Enables fine adjustment of flow and pressure, improving the efficiency of automation processes and allowing for customization according to specific operational needs. |

| Flexibility | Compatible with a wide range of media, including gas, liquids, and oils, making them suitable for various applications across different industries. |

| Energy Efficiency | Reduces energy consumption by optimizing fluid control, leading to significant cost savings and a smaller environmental footprint. |

| Real-time Feedback | Equipped with sensors that provide continuous readings, allowing for immediate adjustments and maintaining system integrity during operation. |

| Durability | Designed to withstand harsh environments, these valves offer longevity, reducing the need for frequent replacements and maintenance. |

| Modularity | Easily integrated into existing systems, providing seamless updates and scalability to meet growing operational demands. |

The primary advantage is its ability to provide precise control over flow and pressure, crucial for applications where accuracy is paramount, such as robotics and advanced manufacturing processes. This precision allows machines to operate more efficiently and adaptively, leading to increased productivity.

Yes, with appropriate material choices and coatings, proportional valves can handle corrosive media, making them adaptable to various industrial needs. This is particularly important in chemical processing and wastewater treatment plants, where the media can be aggressive and damaging to standard materials.

By allowing for smooth operation and reducing the need for manual intervention, these valves enhance system reliability and efficiency. Their ability to respond rapidly to changes in demand translates to minimized downtime and optimized performance, particularly in high-demand settings like manufacturing lines.

Proportional valves are generally low-maintenance components; however, routine checks are essential to ensure their longevity and proper function. Users are advised to inspect for leaks, check the electronic components for wear, and ensure that the fluid media is clean and free from contaminants that could impair performance.

Ambient temperature can significantly impact the performance of proportional valves. Extreme temperatures may affect the viscosity of hydraulic fluids, influencing how effectively the valve can modulate flow. Users should ensure that the valves are selected based on their operational environment and that any environmental factors are accounted for in system design.

The rapid advancements in technology have ushered in new possibilities for the design and functionality of proportional valves. Innovations such as artificial intelligence (AI) and the Internet of Things (IoT) are significantly enhancing the capabilities of these devices by providing smarter control systems that can adapt in real-time. For example, AI algorithms can analyze operational data and predict necessary adjustments to ensure optimal performance, while IoT integration allows for remote monitoring and diagnostics, enabling proactive maintenance.

Furthermore, advancements in material science are leading to the development of new, more durable materials and coatings that extend the lifespan of proportional valves in harsh environments. Components are being designed not only to perform efficiently but also to resist wear and corrosion, ultimately reducing operational costs and extending service intervals.

As industries continue to evolve towards more automated and efficient systems, the role of proportional valves is likely to expand. The growth of renewable energy sources, such as wind and solar, may call for innovative fluid control solutions to manage energy systems effectively. Proportional valves will play a critical role in these systems to optimize fluid dynamics and ensure efficient energy transfer.

Moreover, the increasing focus on sustainability is pushing manufacturers to develop more eco-friendly products. Proportional valves are being designed to minimize energy consumption and reduce waste, aligning with global efforts toward environmental sustainability. This trend is not just a response to regulatory requirements but also reflects changing consumer preferences towards greener technologies.

In addition, smart manufacturing technologies are anticipated to become more integrated with proportional valve technology. This could include enhanced data analytics capabilities and machine learning models that create predictive maintenance schedules, ultimately maximizing uptime and enhancing operational efficiency.

Understanding how proportional valves function in the real world can further underscore their importance in various industries. The following case studies illustrate different applications and highlight the benefits these components deliver.

A major automotive manufacturer implemented proportional valves in their assembly line to control the hydraulic systems used in robotic arms. By utilizing real-time data to adjust the flow rates, they achieved significant improvements in precision and speed during the assembly process. This not only streamlined production but also reduced waste caused by misalignments, leading to a decrease in rework and ultimately improving quality and customer satisfaction.

In a chemical processing plant, proportional valves were integrated into a closed-loop system to control the flow of various chemical substances with different properties. The valves’ ability to maintain a stable flow rate under fluctuating pressure conditions was critical to preventing hazardous situations. By ensuring optimal conditions in the reactor vessels, the plant reduced the incidence of accidents, significantly improving worker safety and product reliability.

A prominent aerospace company began utilizing proportional valves in the hydraulic systems of its aircraft. The need for extreme precision and reliability in flight systems necessitated a robust solution. By adopting proportional valves that provided accurate flow modulation, the company improved the responsiveness of flight controls, leading to enhanced aircraft performance. Additionally, the integration of these valves contributed to reductions in weight, positively impacting fuel efficiency.

The food and beverage industry faces stringent regulatory standards, and the need for precise control in the processing of ingredients is crucial. A leading beverage producer integrated proportional valves to control the influx of raw materials into mixing tanks. This control ensured that mixing ratios were adhered to meticulously, leading to consistent product quality. The solution also allowed for automation, minimizing the risk of human error and ensuring compliance with health and safety regulations.

The integration of proportional valves into modern engineering applications underscores their importance in enhancing precision and efficiency. As industrial demands continue to evolve, these valves provide the flexible, reliable performance necessary for next-generation innovations. By mastering the art of fluid control, they remain an indispensable tool in the engineering toolkit, paving the way for future advancements. The fusion of advanced technologies with traditional fluid management techniques sets a promising trajectory for proportional valves, ensuring they will continue to serve critical functions across diverse applications.

In conclusion, the critical role of proportional valves is woven into the very fabric of modern fluid control systems. Their ability to adapt, respond, and optimize operations guarantees not only enhanced productivity in industrial settings but also promotes safety and sustainability across multiple fields. As engineers and designers strive for excellence in their work, proportional valves will undoubtedly remain at the forefront of innovation, heralding new possibilities for the future.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!