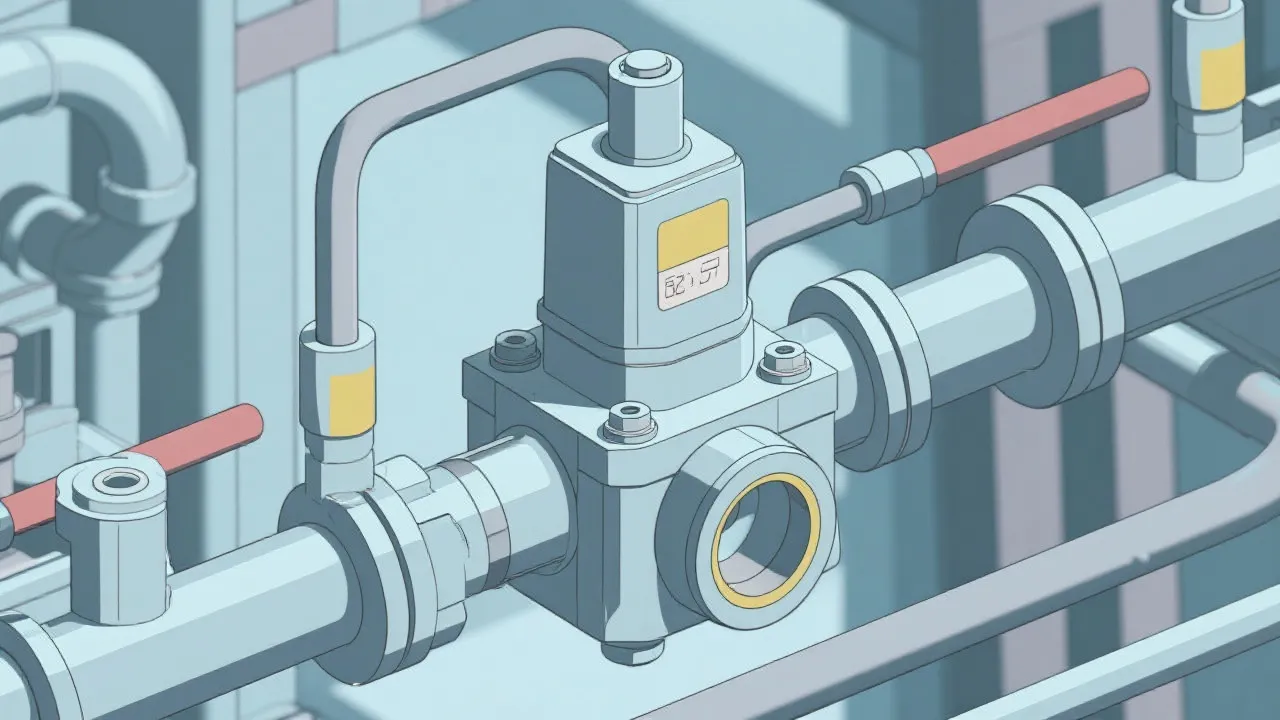

This comprehensive guide delves into the intricacies of proportional valves, essential components in fluid control systems. Proportional valves transform input signals into precise fluid flow adjustments, offering seamless control over fluid dynamics. Their application spans numerous industries, with the ability to handle diverse pressures and flows, making them indispensable in the industrial realm.

Proportional valves are pivotal components within fluid control systems, adept at converting input signals into smoothly controlled fluid flow adjustments. Their imperativeness in modern industry is unmatched, often ensuring that operations run efficiently and safely. Industries ranging from manufacturing to aerospace rely heavily on these valves due to their precision, adaptability, and efficiency. As the landscape of industrial operations evolves, the role of proportional valves becomes increasingly significant in meeting the demands for automation, safety, and efficiency.

At the core of a proportional valve's functionality is its ability to modulate the output flow or pressure in relation to an input signal. This feature allows for fine-tuned control over fluid dynamics, crucial in applications requiring precision, such as chemical processing or hydraulic machinery. By translating electric commands into mechanical movements, these valves regulate the flow with unparalleled accuracy. The proportionality in control means that adjustments can be implemented gradually, allowing for smoother transitions and minimizing potential shocks to the system.

The typical structure of a proportional valve includes an actuator that moves a spool or plate to either increase or decrease flow, depending on the electronic signal it receives. This integrated system often houses feedback mechanisms—such as position sensors—that report the actual flow rate or pressure back to the control unit, ensuring closed-loop control. This closed-loop system enhances reliability and precision, particularly in applications where even minor fluctuations can lead to significant operational issues, such as in pharmaceutical manufacturing where maintaining specific fluid attributes is critical.

Proportional valves are versatile and find applications across a wide range of industries. In the automotive sector, for instance, they play a vital role in the control systems of vehicle suspensions and braking mechanisms. Suspension systems of modern vehicles utilize proportional valves to adjust damping forces and provide a balance between comfort and handling. Similarly, in the aerospace domain, these valves help manage hydraulic systems on aircraft, ensuring stability and control during flights and precise actuation of crucial systems such as landing gear and wing flaps.

In the realm of industrial automation, proportional valves facilitate the seamless operation of machinery by modulating air or fluid flows according to specific requirements. Robotics systems often employ proportional valves to precisely control movement, allowing for intricate processes such as assembly lines where components must be placed with exacting accuracy. This adaptability to diverse pressures and flows underscores their value across multiple industrial applications. Moreover, in sectors like food and beverage processing, proportional valves ensure appropriate flow rates for ingredients, maintaining quality while adhering to safety standards.

Recent advancements in technology have further enhanced the capabilities of proportional valves. The advent of digital control technologies integrated with proportional valves has vastly improved their responsiveness and accuracy. Digital proportional valves can connect directly with computer systems, allowing for sophisticated control algorithms that can adjust the valve behavior dynamically in response to changing operational conditions. These enhancements not only improve performance but also open the door to better diagnostics and predictive maintenance methodologies.

Innovations such as integrated sensors and smart technologies have transformed how fluid control systems are desired. Various modern proportional valves are equipped with diagnostic capabilities that continuously monitor performance metrics and report any irregularities, allowing for proactive maintenance. These developments have expanded their applicability and reliability, making them even more crucial in precision-demanding environments. Furthermore, as industries continue to embrace Industry 4.0 principles, the ability of proportional valves to communicate with other devices and systems creates a holistic approach to automation, contributing to overall operational efficiency and reduced downtime.

While proportional valves offer immense benefits, there are considerations to bear in mind. They may require regular maintenance to ensure optimal performance, especially in environments with demanding operational conditions such as high dirt, moisture, or extreme temperatures. Additionally, selecting the appropriate valve type for a specific application is crucial to achieving the desired outcomes. Misapplication can lead to performance issues, unnecessary wear, or even system failures, requiring careful analysis and an understanding of the operational requirements.

Moreover, the initial investment for high-quality proportional valves can be significant, causing some organizations to hesitate when making purchasing decisions. However, it is essential to consider the total cost of ownership, which includes maintenance, operational efficiency, and potential downtime risks. It is not uncommon for businesses to recoup their initial expenditures within a relatively short timeframe due to the enhanced performance and efficiency provided by these advanced valves.

| Type | Advantages | Disadvantages |

|---|---|---|

| Direct Solenoid Actuated | Fast response, low power requirements, and cost-effective for small flows. | Limited flow range and lower capacity may limit applications. |

| Pilot Operated | Handles larger flows, suitable for high-pressure applications, and often more robust. | Slightly slower response compared to solenoid actuated, requiring more space for installation. |

| Digital Proportional | High precision, integrates easily with electronic systems, and allows for complex control schemes. | Can be costlier to implement, and requires familiarity with digital control systems. |

As industries continue to advance and demand greater precision, proportional valves stand as critical components in achieving these objectives. Understanding their functionality and advancements allows enterprises to leverage their capabilities and enhance operational efficiencies, underscoring their indispensable role in modern engineering and manufacturing landscapes. With the increasing push towards automation and smart technology, the integration of proportional valves into fluid control systems will remain a focal point for industries striving for innovation and improvement.

The journey of adopting proportional valve technology is not one to be taken lightly. Companies must engage in thorough research, and investment appraisal, and ensure that personnel are well-trained in their implementation and maintenance. By embracing the advanced capabilities of proportional valves, industries can position themselves to meet the challenges of the future, ensuring that they are not only competitive but leaders in their respective fields. As the demand for precision in manufacturing processes, automotive safety systems, and aerospace functionality continues to grow, so too does the necessity for proportional valves that can meet these expectations.

Ultimately, the potential of proportional valves is only limited by the creativity and ingenuity with which they are applied. By exploring new uses, integrating them into innovative systems, and continuously refining their operating principles, industries can discover new levels of performance and efficiency. Further investment in research and development, along with collaborative efforts between manufacturers and users, will propel the evolution of proportional valve technology, shaping the future of fluid control systems around the globe.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!