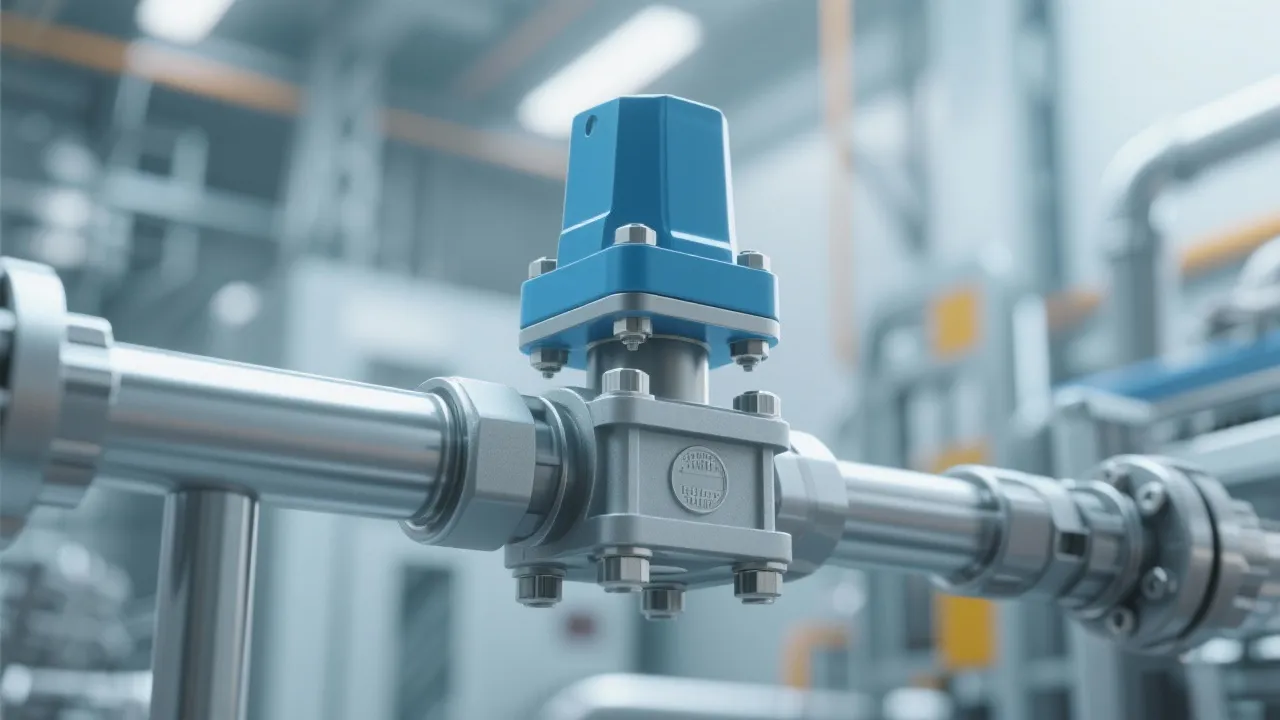

Proportional valves are integral components in various industrial applications, providing precise control of fluid flow, pressure, and direction. Unlike traditional on/off valves, proportional valves offer variable positioning to ensure smooth operation and energy efficiency. Available in different configurations, their versatility enhances performance in sectors ranging from manufacturing to aerospace technology.

Proportional valves have revolutionized fluid control systems by enabling precise governance of flow rates and pressure within a network. In contrast to conventional valves, which typically operate with binary open/close settings, proportional valves can adjust to any position between fully open and fully closed, thus facilitating nuanced control and responsiveness. This capability allows for a wide range of applications, making proportional valves an essential part of modern engineering and industrial processes.

At their core, proportional valves are designed to modulate the output of hydraulic or pneumatic systems. This modulation is achieved through electronic control, allowing for smooth acceleration and deceleration of mechanical processes. Key advantages include enhanced energy efficiency, reduced system wear and tear, and improved operational flexibility. This increased control not only leads to more efficient resource usage but also significantly extends the lifespan of equipment, translating to substantial cost savings in maintenance and replacement.

Moreover, the precision of proportional valves allows operators to optimize processes, resulting in higher product quality and consistency. For example, in a manufacturing setting, controlling the speed and pressure of materials during production can directly affect the characteristics of the final product, such as strength, durability, and finish quality. As a result, industries are increasingly adopting these valves to stay competitive and meet customer demands.

Typically, a proportional valve consists of several key components: solenoid coils, a spool, a spring, and a controller. The controller receives input signals—often from a sensor that measures system parameters like pressure or flow rate—and adjusts current to the solenoids. This input leads to the movement of the spool, which varies the valve opening and controls the fluid flow. The interaction of these components allows for finely-tuned control over the system, akin to adjusting the volume on a radio, offering precise control rather than abrupt changes.

Additionally, the operation of proportional valves can be influenced by various external factors. For instance, temperature variations can affect the viscosity of the fluid being controlled, thus impacting the valve's performance. Therefore, modern proportional valves often incorporate feedback mechanisms and diagnostics that help maintain optimal functionality even under varying conditions.

The versatility of proportional valves makes them indispensable across a myriad of sectors. In manufacturing, they ensure precise control in injection molding machines, enabling accurate material dispensing and cycle times. In aerospace, they manage critical systems, from hydraulic actuation of landing gear to fuel flow regulation in engines, ensuring safety and efficiency in complex operations.

In the automotive sector, proportional valves are utilized in various applications, including active suspension systems that adjust ride height and comfort in real-time based on driving conditions. Furthermore, they are employed in braking systems to modulate brake pressure for smoother deceleration and increased control over vehicle dynamics.

Energy production and management also greatly benefit from proportional valve technology. In the oil and gas industry, these valves help control flow rates in pipelines, optimizing transport efficiency and reducing the risk of leaks and spills. Additionally, they play a significant role in managing the fluid flow in power plants, enhancing the efficiency of energy generation and distribution processes.

Beyond these examples, the adaptability of proportional valves enables their use in robotics, medical devices, and water treatment facilities, showcasing their extensive applicability across various technological landscapes.

Recent innovations in proportional valve technology have increasingly focused on integrating the Internet of Things (IoT) and smart sensors, enhancing their functionality through real-time monitoring and predictive maintenance capabilities. These advancements not only increase system uptime but also provide data-driven insights that contribute to overall process optimization.

For instance, by utilizing IoT-connected sensors, operators can continuously monitor the performance of proportional valves, identifying potential issues before they develop into significant problems. This proactive approach to maintenance ensures that systems remain operational and reduces the likelihood of costly downtimes. Moreover, insights gained from data analytics can inform future upgrades and modifications to systems, allowing for continuous improvement.

The integration of artificial intelligence (AI) further enhances proportional valve technology. Using machine learning algorithms, systems can learn from historical data and adjust their operations accordingly, continuously optimizing processes without direct human intervention. This feature can lead to significant efficiency gains, as well as freeing human operators to focus on higher-level decision-making tasks.

| Feature | Proportional Valves | Traditional Valves |

|---|---|---|

| Control Type | Variable positioning | On/Off only |

| Energy Efficiency | High due to precise control | Moderate, often inefficient |

| Maintenance | Reduced due to less wear | Higher frequency required |

| Installation Complexity | Moderate, requires control systems | Simpler, less sophisticated |

| Cost | Higher initial investment, long-term savings | Lower upfront cost, higher long-term operational cost |

| Response Time | Fast and adaptive | Slower and fixed |

| Automation Compatibility | Highly compatible with automated systems | Limited integration options |

As industrial systems become increasingly complex and the demand for efficiency grows, proportional valves will play a pivotal role in modernizing operations. Their ability to seamlessly integrate with advanced control systems makes them a cornerstone of innovative industrial engineering, promising continued development and adaptation in addressing future challenges.

Future advancements may include the integration of more sophisticated AI algorithms capable of predictive analytics and real-time optimization of fluid control systems. Such innovations will likely lead to greater automation in industrial processes, further expanding the scope and application of proportional valves.

As industries continue to seek ways to improve efficiency and reduce costs in an environmentally responsible manner, the fundamental role that proportional valves play in achieving these goals cannot be overstated. By continually evolving alongside technological advancements, proportional valves will undeniably shape the future landscape of fluid control technologies.

In conclusion, as we embrace the challenges of modern manufacturing and industrial applications, proportional valves stand as a testament to innovation in fluid control, embodying the principles of efficiency, precision, and sustainability that are vital for future advancements.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!