Proportional valves are crucial components in numerous industrial and automotive systems, providing precise control of fluid flow and pressure. These valves play a pivotal role in optimizing energy use, enhancing system efficiency, and maintaining safety standards across diverse sectors, from manufacturing to aerospace. This article explores the intricacies and applications of proportional valves.

Proportional valves are utilized extensively in modern industrial and automotive systems for their exceptional ability to provide precise control over the flow and pressure of gases or fluids. These valves are fundamental components in applications where fine adjustment of hydraulic parameters is pivotal for efficient operations. Their design allows for improved control, leading to enhanced performance in a variety of settings, including automotive, aerospace, and manufacturing. With the advent of automation and increased demand for precision in equipment, the significance of proportional valves has only risen.

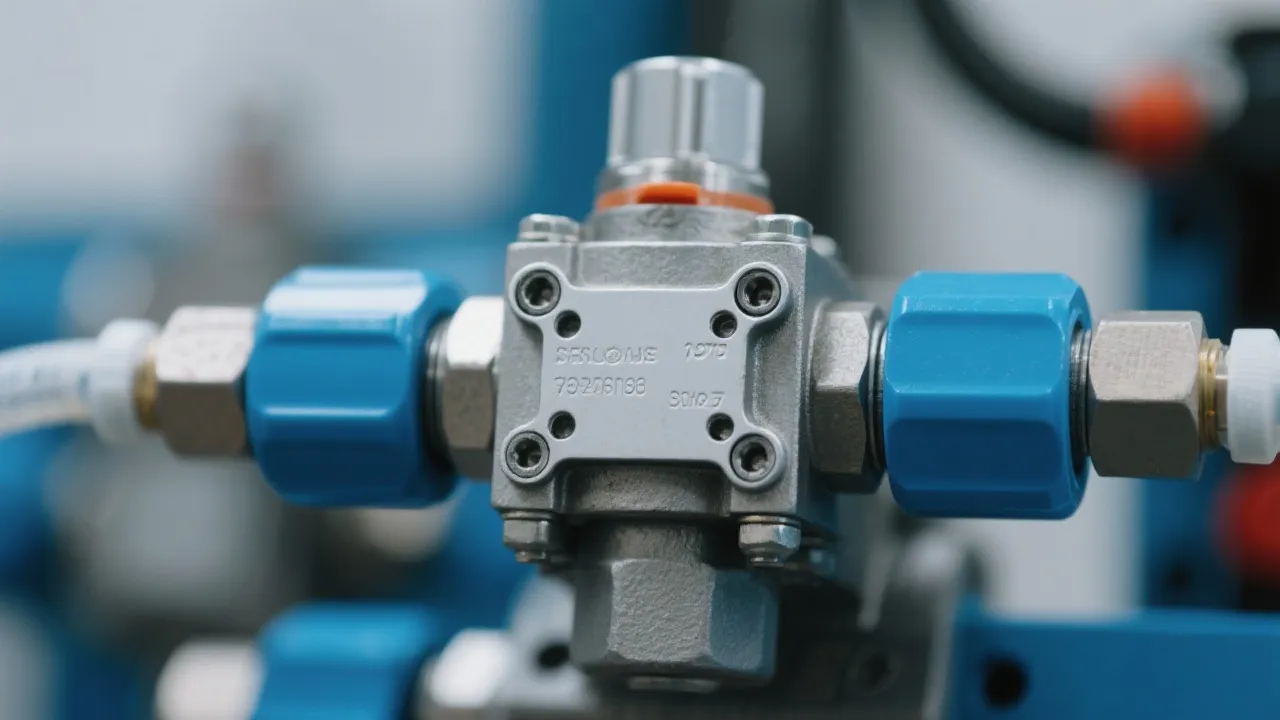

Unlike conventional on/off valves that strictly operate in binary modes, proportional valves excel by providing a variable output based on a specific input signal. This functionality enables them to open partially, adjusting the flow proportionally according to the demands of the system. Such modulation of control fosters smoother operation and increased operational efficiency. The mechanics behind proportional valves usually involve electronic systems, employing solenoids or servos to move the valve spool in response to demand signals, thus dynamically controlling the flow and pressure. Furthermore, many modern proportional valves incorporate advanced technologies such as feedback loops and sensor integration, which significantly enhance their performance and reliability by allowing for continuous monitoring and adjustment.

Proportional valves can be categorized based on their function and construction, generally divided into three main types:

Proportional valves find immense utility across various sectors, showcasing their versatility and precision. In the automotive industry, they play crucial roles in enhancing performance in transmission control systems, oil cooling systems, and fuel injection systems. For instance, in fuel systems, proportional valves help finely tune the fuel-air mixture, which improves combustion efficiency and reduces emissions. In industrial applications, these valves contribute to machine tool operations, automated assembly lines, and complex manufacturing processes where precise fluid control is critical. Examples include controlling the force applied by a hydraulic press or modulating the fluid flow in CNC machining processes.

The benefits offered by proportional valves extend far beyond just flow and pressure control. By providing enhanced energy efficiency, these valves help reduce energy costs significantly, particularly in systems subjected to variable operational demands. Moreover, they help minimize wear and tear on system components through their smooth operation, effectively extending the lifespan of equipment. Improved system response times, another significant advantage, lead to increased productivity in manufacturing processes, with quicker reaction to changes in operating conditions and immediate adjustments as required. Altogether, this results in lower overall operating costs and aligns with overall objectives of sustainability and efficiency in modern industry.

The proper selection of a proportional valve is crucial and involves careful consideration of several factors such as the type of control needed, specific application requirements (including pressure range, flow rate, type of fluid, and installation space), and environmental conditions that might affect the valve’s operation. The temperature range and the presence of contaminants in the fluid can also dictate the choice of materials and seals used in the valve. Compatibility with existing systems and components, budget constraints, and expected valve service life are critical aspects that further influence the selection process. Each parameter influences how well the valve will perform in its intended application. Furthermore, incorrect selection can lead not only to reduced efficiency but also to potential failure of the entire system, underscoring the importance of a comprehensive evaluation during the purchasing process.

The market for proportional valves is diverse and competitive, featuring numerous suppliers who offer a wide range of options to suit different applications. Industry leaders such as Bosch Rexroth, Parker Hannifin, Moog Inc., and Danfoss are well-known for their extensive product lines and commitment to quality and innovation. These companies consistently update their offerings to adapt to evolving technological trends and market needs. Pricing for proportional valves can vary widely based on specifications, functionalities, and features, often ranging from a few hundred to several thousand dollars per unit, depending on the required capabilities and materials used. Most suppliers provide detailed product catalogs and technical specifications to assist customers in identifying the right valve for their needs, ensuring that engineers and procurement specialists are equipped with the necessary information to make informed decisions.

As technology continues to advance, the future of proportional valves appears promising. The development of smart valves that can communicate with other components within a system via IoT (Internet of Things) technology is underway. Such features will allow for real-time data analysis and adjustments, making these valves even more efficient and responsive. The need for energy-efficient solutions and the growing trend towards automation will further drive innovations and upgrades in proportional valve technologies. Moreover, industries are increasingly focusing on reducing energy consumption and environmental impact, prompting manufacturers to integrate sustainable practices into their designs. This trend will likely include the development of new materials that are more environmentally friendly and efficient in terms of manufacturing processes.

Proportional valves are increasingly being integrated with sophisticated control systems, such as PLCs (Programmable Logic Controllers) and advanced servo control units. This integration allows for higher levels of responsiveness and flexibility within fluid systems. By utilizing sensors that provide real-time feedback, the control systems can instantly adjust the valve’s position to meet the changing demands of the application, ensuring optimal performance and preventing potential issues before they arise. These advancements not only enhance operational efficiency but also open up new possibilities for automation in various sectors. For example, automated assembly lines can utilize proportional valves to fine-tune processes in real-time, reducing waste and increasing throughput.

Despite their many advantages, proportional valves do come with challenges. One major challenge lies in their initial complexity during setup and configuration. Proper calibration is essential for achieving the desired performance, and this often requires significant expertise and experience. Additionally, these valves can be sensitive to contamination, which necessitates stringent maintenance protocols. Contaminants such as debris or particulates can impede their operation and lead to malfunction or inefficiency. Furthermore, the initial cost of purchasing and installing high-quality proportional valves can be a barrier for some organizations, particularly those with limited budgets. Overcoming these challenges involves careful planning, regular maintenance, and thorough training for operating personnel to ensure that the systems are used effectively.

To ensure the longevity and optimal performance of proportional valves, routine maintenance is essential. This may involve regular inspections to identify early signs of wear or failure, cleaning of fluid pathways to avoid contamination, and lubrication of moving parts where applicable. Professionals should also monitor performance metrics to identify any unusual fluctuations that could indicate potential issues. Timely replacement of seals and components based on manufacturers' recommendations will also prolong the service life of the valves. Investing in a robust maintenance program can lead to reduced downtime and lower costs associated with emergency repairs or replacements.

Proportional valves are pivotal components in optimizing modern fluid systems, offering enhanced control, efficiency, and reliability. Their ability to modulate flow and pressure precisely leads to significant improvements in performance across various applications. As technology continues to evolve, these components are poised to become even more sophisticated, further cementing their crucial role in complex hydraulic and pneumatic systems across industries. From automotive to industrial machinery, the demand for precision fluid control is undeniable, highlighting the integral value of proportional valves in the future of mechanical design and engineering.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!