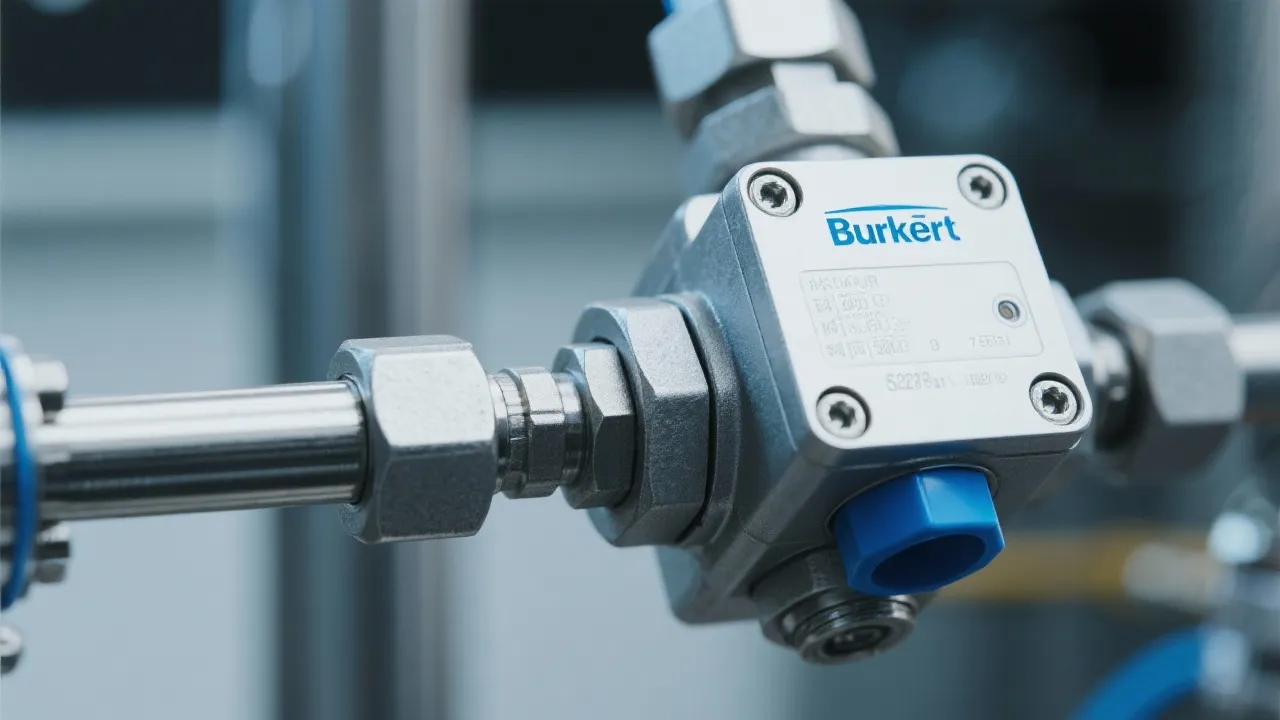

Burkert Proportional Valves are essential components used in precision fluid control, known for their reliability and wide application range. These valves enable exact fluid regulation across various industrial settings. The intersection of engineering expertise and technological advancement makes them critical to system efficiencies in sectors like automotive, food processing, and pharmaceuticals.

Proportional valves are pivotal in modern fluid control systems, providing precise management of flow rates across diverse industrial processes. Among the myriad of choices, the Burkert Proportional Valve stands out distinctly in the market. It is renowned not only for its precision but also for its adaptability, making it a crucial player in regulating fluid dynamics with high accuracy. Unlike traditional valves that often serve a binary function of "on" or "off", proportional valves enable variable flow control, allowing for nuanced modulation that meets the specific requirements of various applications.

The operational principle of proportional valves is fundamentally based on the idea of exemplifying fluid flow dynamics through electronic controls. These valves integrate feedback mechanisms that enable them to respond to changes in system pressure and demand dynamically. Consequently, the need for additional components such as flow meters and controllers may be mitigated, resulting in a more compact and efficient design. This added layer of sophistication plays a vital role in enhancing process efficiency, product consistency, and operational safety.

The Burkert Proportional Valve series is recognized for its linear control characteristic that ensures smooth and continuous adjustments, which are vital for applications requiring variable flow profiles rather than simple on/off control. One of the most distinguishing features of Burkert valves is their ability to deliver highly accurate positioning of the flow rate. This accuracy is instrumental in processes where slight deviations can lead to significant variations in product quality.

Additionally, these valves exhibit high efficiency by minimizing energy consumption throughout industrial systems. The incorporation of advanced actuator technologies in their design enhances response times and reduces lag—a crucial factor for maintaining process stability and uniformity. Consequently, operators can rely on these valves to react quickly to setpoint changes, ensuring that the desired flow conditions are achieved without delay. Moreover, Burkert valves can be integrated seamlessly with digital controls, providing further opportunities for automation and process optimization.

The material composition of Burkert Proportional Valves also deserves mention. They are constructed using materials that are not only durable but also capable of withstanding adverse environmental conditions, ensuring that the valves perform consistently over extended periods. This durability allows for extended maintenance intervals, ultimately leading to a lower total cost of ownership for operators.

Burkert Proportional Valves find widespread employment across multiple industries, including automotive, pharmaceuticals, food processing, and many others. Each industry presents unique challenges that these valves help resolve effectively through their advanced design and operational capabilities.

In the automotive sector, for instance, proportional valves are pivotal in managing fuel injection systems. This functionality directly contributes to enhanced fuel efficiency and effective emissions control. For modern automobiles, where environmental regulations are increasingly stringent, the capability to fine-tune fuel delivery is crucial. The resultant improvement in combustion efficiency not only benefits the vehicle's performance but also aligns with global efforts towards sustainability:

For example, Burkert valves equipped with innovative pressure sensors can adjust the fuel mixture in real-time based on the engine's performance demands, maximizing efficiency while maintaining compliance with emission standards.

In the pharmaceutical industry, where the accuracy of fluid regulation can impact batch consistency, Burkert Proportional Valves ensure that liquids and formulations are mixed to exact specifications. In many cases, the validation of processes requires stringent adherence to regulatory requirements, necessitating the use of technology that guarantees repeatable results. With these valves, operators can monitor flow rates with precision, ensuring that every batch meets the high standards expected in pharmaceutical production:

For instance, during the mixing of medicinal compounds, even a small variance in flow rates can lead to ineffective medication. Burkert valves allow for precise control, thus supporting the integrity and efficacy of the pharmaceutical products.

In the food processing sector, Burkert Proportional Valves are essential for maintaining the integrity of product formulations. They play a critical role in delivering consistent ingredient mixes, which is fundamental for product quality and labeling accuracy. By ensuring that liquids are dispensed in precise quantities, these valves help in maintaining flavor profiles and nutritional content, alongside extending product shelf life.

Moreover, the control afforded by these valves translates to operational flexibility; manufacturers can switch between recipes or products with minimal downtime, thereby enhancing throughput. Such capability is particularly advantageous in an industry where consumer preferences can fluctuate rapidly:

For instance, when switching production from one beverage flavor to another, Burkert valves can be adjusted swiftly to deliver the exact proportions of each ingredient, ensuring minimal product waste and consistent quality.

| Valve Type | Control Range | Material Composition | Flow Capacity | Operating Pressure |

|---|---|---|---|---|

| Type 8702 | 1:1000 ratio | Stainless Steel/Brass | 0-250 l/min | Up to 10 bar |

| Type 8802 | 1:2000 ratio | High-grade Pneumatic | 0-400 l/min | Up to 8 bar |

| Type 8205 | 1:1500 ratio | Polymer Composite | 0-200 l/min | Up to 6 bar |

| Type 8600 | 1:1000 ratio | Stainless Steel | 0-300 l/min | Up to 12 bar |

When comparing the different types of Burkert Proportional Valves, it's essential to consider several parameters, including their control range, flow capacity, and material composition. Each valve is tailored to specific applications and operating conditions, allowing users to select the most appropriate valve for their unique operational demands. For example, users needing higher flow rates might prefer the Type 8802, while others prioritizing compactness or lower weight might lean towards the Type 8205.

There are several compelling reasons for choosing Burkert as your valve manufacturer. Burkert valves are engineered to withstand the rigorous operational demands familiar to many industries. Their robust construction not only minimizes maintenance needs but also enhances longevity and reliability—factors that directly contribute to lower operational costs over time.

The performance of Burkert Proportional Valves is backed by a legacy of engineering excellence and innovation. As a company, Burkert continuously invests in research and development to ensure that its products meet the evolving needs of its customer base. Furthermore, each valve undergoes stringent quality control measures, guaranteeing that it meets the high standards that users expect from a reputable manufacturer. This focus on quality means that operators can trust Burkert valves to perform consistently under variable operational conditions, from high flow rates to extreme temperatures:

Furthermore, Burkert provides comprehensive support and guidance, ensuring that customers can seamlessly integrate these valves into their systems to achieve optimal functionality. Technical assistance, installation advice, and after-sales support form an essential part of the customer experience.

Q: What is the primary benefit of using a Burkert Proportional Valve?

A: The primary benefit is the ability to achieve precise fluid control, which is imperative for processes requiring exact flow specifications. Moreover, this precision helps to optimize overall system performance and ensures product quality in varied applications.

Q: Are Burkert Proportional Valves suitable for high-temperature applications?

A: Yes, certain models are designed to operate effectively under high-temperature conditions. For example, some specific valves can withstand temperatures exceeding 100°C, making them versatile across different industrial environments that demand such resilience.

Q: How do Burkert Proportional Valves contribute to system efficiency?

A: By allowing fine-tuned control over flow rates, Burkert Proportional Valves enhance system productivity and reduce energy consumption, thereby optimizing operational efficiency. This is particularly crucial in automated environments where precision and consistency are paramount.

Q: Can Burkert Proportional Valves handle aggressive media?

A: Yes, the material selection for Burkert Proportional Valves encompasses a variety of composites and metals tailored to handle aggressive chemicals, making them suitable for use in chemical processing applications. Different models are available with specialized coatings that enhance corrosion resistance.

Q: How do I integrate a Burkert Proportional Valve into my existing system?

A: Integration typically involves connecting the valve to existing control systems and ensuring proper setup for feedback signals. Burkert offers comprehensive technical documentation and support services to assist in the integration process, ensuring minimal disruption to current operations.

Burkert recognizes the importance of continuous education and support for its clients. As such, they offer an array of training programs aimed at educating users on the effective operation and maintenance of their proportional valves. These training sessions cover a range of topics, from installation best practices to troubleshooting common issues:

Through workshops and online webinars, clients can stay informed about the latest advancements in fluid control technology and learn how to leverage Burkert Proportional Valves to achieve maximum efficiency.

As industries continue to evolve and the demand for efficiency and precision in fluid control grows, Burkert is at the forefront of integrating new technologies into their proportional valves. Advanced connectivity features, such as IoT (Internet of Things) implementation, are on the horizon. Enhanced connectivity will allow for real-time monitoring and feedback, enabling operators to make immediate adjustments to their processes based on live data, thereby enhancing overall system performance significantly.

Moreover, innovations like adaptive algorithms built into the control mechanisms could lead to self-tuning valves, which can optimize their performance based on varying operational conditions. This adaptability will significantly reduce the need for manual recalibrations and adjustments, freeing up operators to focus on other critical aspects of process management:

As we look to the future, the fusion of artificial intelligence in fluid control promises to revolutionize traditional practices, making systems smarter and more adaptive than ever before.

In conclusion, Burkert Proportional Valves are an indispensable asset in industries focusing on precise fluid control. Their design, robustness, ease of integration, and efficiency empower industries to maintain high standards of process efficiency and product quality. By investing in such advanced valve technology, businesses can ensure that their operational processes meet the stringent demands of modern-day manufacturing and processing requirements. Embracing the capabilities provided by Burkert not only streamlines operations but also paves the way for innovations that will define the future of fluid dynamics and control systems.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!