Rexroth Counterbalance Valves play a vital role in hydraulic systems by ensuring load control and system safety. This guide explores the function and importance of these valves, highlighting their engineering excellence and application value. Known for their precision, Rexroth Counterbalance Valves are essential in various industries like construction and manufacturing where stability and safety are paramount.

In the realm of hydraulic systems, Rexroth Counterbalance Valves stand as pivotal components, renowned for their technical precision and safety assurance. These valves, integral to load holding applications, play an essential role in maintaining system stability and efficiency. Unlike other valves, the Rexroth Counterbalance Valve is specifically designed to prevent uncontrolled load descent, acting as a safeguard against potential system failures. The importance of these valves becomes even more pronounced when considering the dynamic and often unpredictable nature of hydraulic systems where maintaining load control is crucial to overall operation safety and effectiveness. In this comprehensive exploration, we will delve deeper into the functionality, features, applications, and overall significance of Rexroth Counterbalance Valves within the broader context of hydraulic systems.

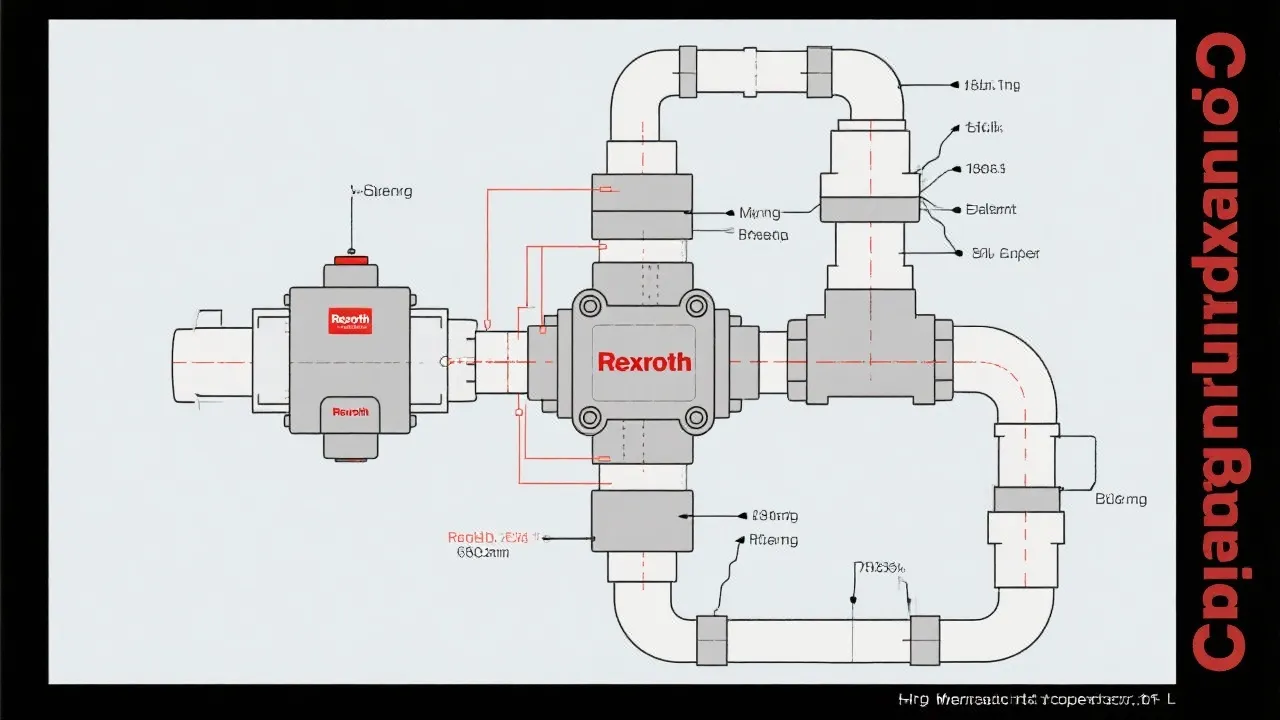

Rexroth Counterbalance Valves are engineered to balance an opposing load, ensuring it does not exceed desired limits which might otherwise lead to a catastrophic failure. By counteracting weights and controlling loads, these valves contribute to a safe hydraulic environment. Under operational conditions, these valves allow for precise control of forces within the circuitry, providing a dependable solution to hydraulic pressure hazards. The way these valves operate is based on a fundamental principle: they utilize a spring-loaded piston mechanism to maintain load stability. When the load exerts downward pressure on the piston, the valve opens to allow hydraulic fluid flow while simultaneously resisting any downward motion until the pressure reaches a predetermined level. This mechanism ensures that rapid or uncontrolled descent is effectively prevented, providing peace of mind for operators and engineers alike.

Rexroth Counterbalance Valves are crucial across various sectors such as construction, manufacturing, and heavy machinery industries. In the construction industry, these valves are essential in crane and lift applications where precise load control is imperative. Their presence allows cranes to safely lift and lower heavy materials without risking structural or personnel safety. Additionally, in the manufacturing sector, where assembly lines rely heavily on hydraulic systems, these valves maintain equilibrium in complex machine assemblies requiring strict load management.

Moreover, the use of Rexroth Counterbalance Valves extends into the agricultural sector, where they help in stabilizing hydraulic equipment, such as forklifts and loaders used in farming operations. By preventing unintended descent of heavy loads, they help in securing materials and enhancing productivity. In mobile equipment operations, such as on excavators or backhoes, the reliability of these valves ensures that operations can proceed with minimal risk, facilitating more efficient use of machinery and reducing operational hazards.

Additionally, in the aerospace industry, the application of these valves can be observed within hydraulic actuation systems where precision and safety are non-negotiable requirements. These systems often operate under extreme conditions, meaning that the dependability of Counterbalance Valves becomes even more critical, ensuring that systems are fail-safe.

| Type | Characteristics | Top Use Case |

|---|---|---|

| Rexroth Standard | Reliable, cost-effective, and high-quality materials | General hydraulic applications in manufacturing |

| High-Load Models | Enhanced capacity with greater load management capabilities | Heavy-duty machinery and construction equipment |

| Compact Designs | Space-saving and efficient for smaller system configurations | Limited-space applications in robotics |

| Customizable Solutions | Tailored specifications to meet unique operational needs | Specialized industrial applications with specific requirements |

From an expert's perspective, Rexroth's engineering prowess is evident in the consistent performance and durability of their Counterbalance Valves. Their commitment to quality is redundant through rigorous testing and adherence to industry standards, ensuring their products withstand the highest operational demands. Professionals in the hydraulic sector often praise Rexroth for combining innovation with reliable utility. Their utilization of premium materials and cutting-edge technologies in the design and manufacturing processes stands as a testament to their superiority and reliability.

Moreover, Rexroth actively seeks feedback from end-users and engineers to continuously improve their product offerings. This proactive approach not only enhances the effectiveness of their valves but also addresses emerging challenges in hydraulic applications. As technology advances, the integration of smart technologies and IoT capabilities within their products exemplifies Rexroth's dedication to maintaining a competitive edge in the hydraulics marketplace. With features like predictive maintenance and real-time monitoring, Rexroth positions itself at the forefront of hydraulic engineering, providing added value and security to users worldwide.

Proper installation and maintenance of Rexroth Counterbalance Valves are crucial for ensuring optimal performance and longevity. It is essential to follow best practices during the installation phase to avoid future complications. The installation site should be assessed to confirm that it meets the valve’s specifications and operational requirements. Additionally, ensuring correct orientation and alignment, as well as the use of compatible hydraulic fluid, is paramount to the successful operation of these valves.

Maintenance routines should include regular inspections of the valve's functionality, checking for signs of wear or leakage, and cleaning components to avoid performance issues. Operators should adhere to recommended pressure limits and regularly communicate any abnormalities observed during operation to facilitate timely interventions. Implementing a strict maintenance schedule not only enhances the lifespan of the valves but also contributes to the overall safety and reliability of hydraulic systems.

Furthermore, training employees on proper handling techniques and functional understanding of the Rexroth Counterbalance Valves can prevent mishaps during operation and maintenance. By fostering a culture of safety and diligence, organizations ensure optimal utilization of their hydraulic systems and components.

In conclusion, Rexroth Counterbalance Valves are indispensable components of contemporary hydraulic systems, embodying both safety and effectiveness. Their adaptive use across multiple sectors accentuates their relevance in today's industrial applications, ensuring operational safety without compromising efficiency. As industries advance, Rexroth continues to innovate, solidifying its position as a leader in hydraulic engineering solutions. By focusing on the needs of their customers and adapting to the evolving landscape of technology, Rexroth remains at the forefront of hydraulic innovation. As we move into an era of increased automation and sophisticated hydraulic systems, Rexroth Counterbalance Valves will undoubtedly play an integral role in setting industry standards and enhancing productivity across the globe.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!