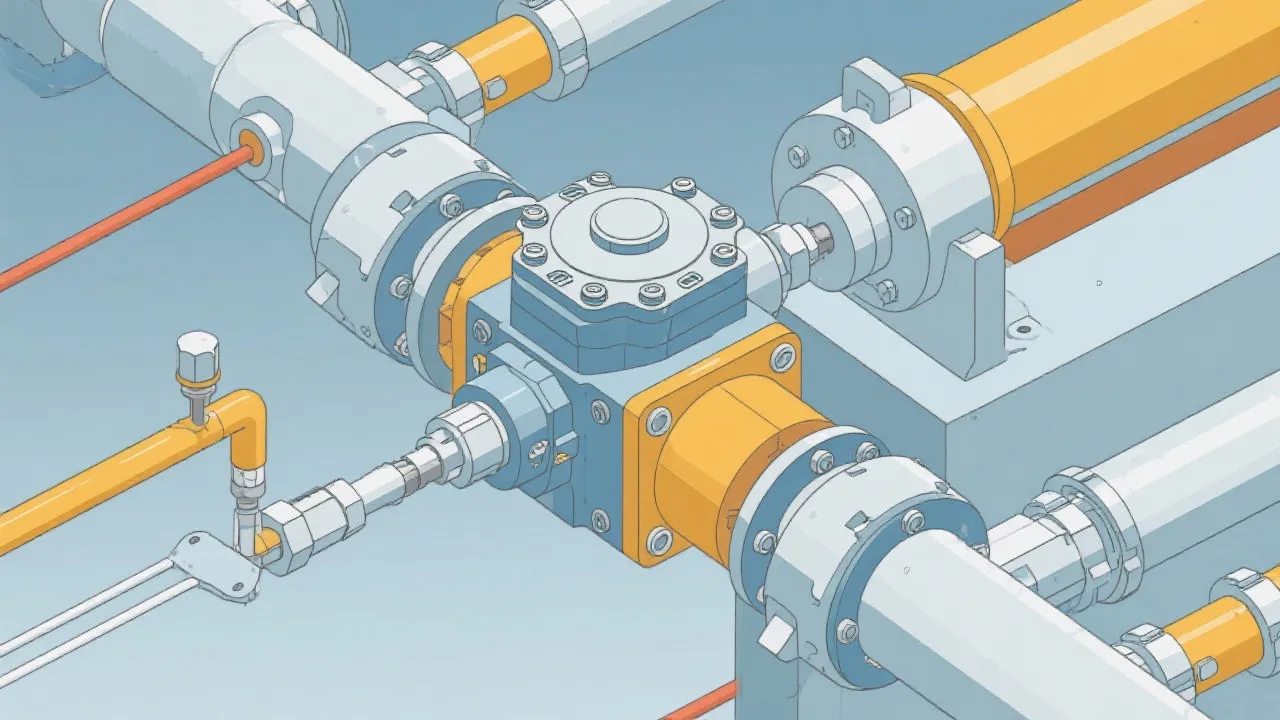

The Rexroth Counterbalance Valve is a crucial component in hydraulic systems designed to control fluid flow and maintain pressure stability. Recognized for its durability and precision, this valve is integral to various industrial applications, enhancing system performance and safety. This article explores the function, significance, and technical nuances of the Rexroth Counterbalance Valve in modern hydraulic systems.

Counterbalance valves are pivotal in the realm of hydraulic systems, serving the essential purpose of controlling fluid pressure and stabilizing operations within various industrial applications. Among these, the Rexroth Counterbalance Valve stands out due to its advanced design and reliable performance. These valves are not only a functional component but play a critical role in ensuring safety, efficiency, and longevity of hydraulic machines.

To fully appreciate the impact of counterbalance valves, it is important to understand their mechanics. When a load is applied, hydraulic systems rely on counterbalance valves to maintain pressure stability during movement. Without these valves, fluid can quickly escape back to the reservoir when hydraulic actuators (such as cylinders) retract. This can lead to uncontrolled movement of machinery, which poses serious risks in industrial environments.

Counterbalance valves work by allowing fluid to flow out of the actuator only when a specific preset pressure is reached. The valve restricts flow until internal pressures equate to an external load, which effectively halts the actuator. This regulates the flow of hydraulic fluid, balancing the force of gravity and the force exerted by the actuator, allowing for smooth and controlled operation.

The primary function of the Rexroth Counterbalance Valve is to regulate the pressure within hydraulic circuits, preventing excess fluid flow and ensuring controlled movements of hydraulic actuators. This mechanism is indispensable for maintaining the stability and efficiency of systems, particularly in load-holding applications. By incorporating a Rexroth Counterbalance Valve, system operators can ensure safety and reduce the risk of uncontrolled loads, which could lead to equipment damage or operational hazards. Its design typically includes a pressure relief feature that activates at predetermined thresholds, maintaining the system within safe operating limits.

In scenarios such as lifting heavy loads, the absence of a counterbalance valve would mean a risk of descending too quickly or even free-fall, which can be catastrophic. This stability provided by the Rexroth valves is crucial in various applications, solidifying their importance in hydraulic engineering and system design.

The technical specifications of Rexroth Counterbalance Valves encompass various models designed to accommodate different operational parameters. These valves are known for their robust construction, high-pressure tolerance, and flexibility in terms of control settings, allowing customization to specific system requirements. The ability to adapt to diverse industrial applications makes these valves integral to the design of hydraulic systems.

Standard features often include screw-in or modular configurations, offering ease of installation and maintenance. Additionally, the precision-engineered components of these valves contribute to their long lifespan and minimal maintenance demands. Most models support extensive performance testing and meet high standards for reliability. Typical materials used in construction include high-grade steel and composite materials designed to resist wear and corrosion, ensuring the valve can operate under extreme environmental conditions.

Moreover, attention to detail in the design, such as low leakage rates and accurate response to pressure changes, enhances the reliability and efficiency of these devices. Whether used in mobile equipment or manufacturing environments, Rexroth valves continue to demonstrate their versatility.

Rexroth Counterbalance Valves find extensive usage across diverse industries where hydraulic systems are prevalent. Common applications include construction machinery, material handling, and industrial automation systems. Their ability to effectively manage load pressures is critical in these sectors, ensuring seamless and safe operations under varying load conditions.

1. **Construction and Heavy Machinery:** In cranes, excavators, and other construction machinery, counterbalance valves ensure that loads can be held safely in position during operation and remain stable while repositioning. This enhances overall safety for operators and bystanders during activities such as lifting and moving large prefabricated components.

2. **Material Handling:** Automated warehouses and distribution centers utilize counterbalance valves in various handling equipment, such as forklifts and stackers, to maintain control and prevent incidents when lifting and transporting goods. Proper load management is essential to minimize product damage and improve efficiency in logistics.

3. **Industrial Automation Systems:** Many robotic systems rely on hydraulic actuators for precise movements. In this context, counterbalance valves provide necessary support to achieve the required balance and stability, allowing systems to operate with precision and reduced energy consumption.

| Model | Pressure Range | Flow Rate | Application |

|---|---|---|---|

| Rexroth CBV-10 | 0 to 350 bar | Up to 200 L/min | Light to medium industrial applications |

| Rexroth CBV-20 | 0 to 420 bar | Up to 500 L/min | Heavy-duty systems, construction equipment |

| Rexroth CBV-30 | 0 to 500 bar | Up to 1000 L/min | Large-scale hydraulic systems |

This comparative analysis underscores the versatility of Rexroth Counterbalance Valves and their applicability to various systems, affirming their place within hydraulic engineering solutions. By selecting the appropriate model for the specific operational requirements, engineers can maximize performance and efficiency across applications.

Ensuring the optimal operation of a Rexroth Counterbalance Valve involves regular maintenance checks, focusing on cleaning, component inspection, and pressure calibration. Troubleshooting common issues such as leaks or pressure imbalance requires a systematic approach, referring to the manufacturer's guidelines for resolution. Regular inspection schedules help detect wear and tear early, preventing catastrophic failures.

1. **Cleaning:** Dust and contaminants can impede valve performance. Regular cleaning of the hydraulic fluid and ensuring that the surroundings of the valve are free from debris helps maintain its functionality.

2. **Inspection:** Scheduled inspections should involve checking connection fittings, seals, and O-rings for signs of wear or damage. Any signs of leakage at these points can lead to significant performance issues.

3. **Pressure Calibration:** Monitoring and calibrating the pressure settings according to operational manuals ensures the valve functions within safe limits. This reduces the risk of system overpressure or undervalued pressure scenarios that could lead to failures.

4. **Upgrade and Replacement:** When technological advancements or better models become available, consider upgrading your counterbalance valves. Such enhancements can lead to more efficient operation, consuming less energy while providing the same or improved performance levels.

A: It primarily regulates hydraulic pressure and ensures stability by preventing uncontrolled fluid flow, particularly in load-holding scenarios.

A: Rexroth valves are renowned for their durability, precision control, and ability to handle high-pressure applications.

A: Regular cleaning, inspection, and calibration according to the operational manual are pivotal for maintenance.

A: Yes, like any mechanical device, counterbalance valves can fail due to wear, improper handling, or insufficient maintenance. Regular care is essential for prolonging the lifetime of the equipment.

A: While some experience with hydraulic systems is beneficial, replacing a counterbalance valve can typically be completed with basic hand tools. Ensure to follow manufacturer instructions and safety guidelines during replacement.

In conclusion, Rexroth Counterbalance Valves are integral to efficient and safe hydraulic systems. By offering precision control and robust design, these valves remain a top choice for industries seeking reliable solutions for pressure management and load control. Their ability to adapt to various operational requirements and maintain consistent performance under diverse conditions makes them invaluable in advancing technology and safety in industrial applications.

As hydraulic systems evolve with ongoing advancements, the role of counterbalance valves like those manufactured by Rexroth will continue to be influential. By investing in quality components and prioritizing maintenance, industries can ensure operational excellence and a secure working environment, thereby maximizing productivity and organizational success. The integration of counterbalance valves is not merely an enhancement but a necessity for any operation involving hydraulic machinery.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!