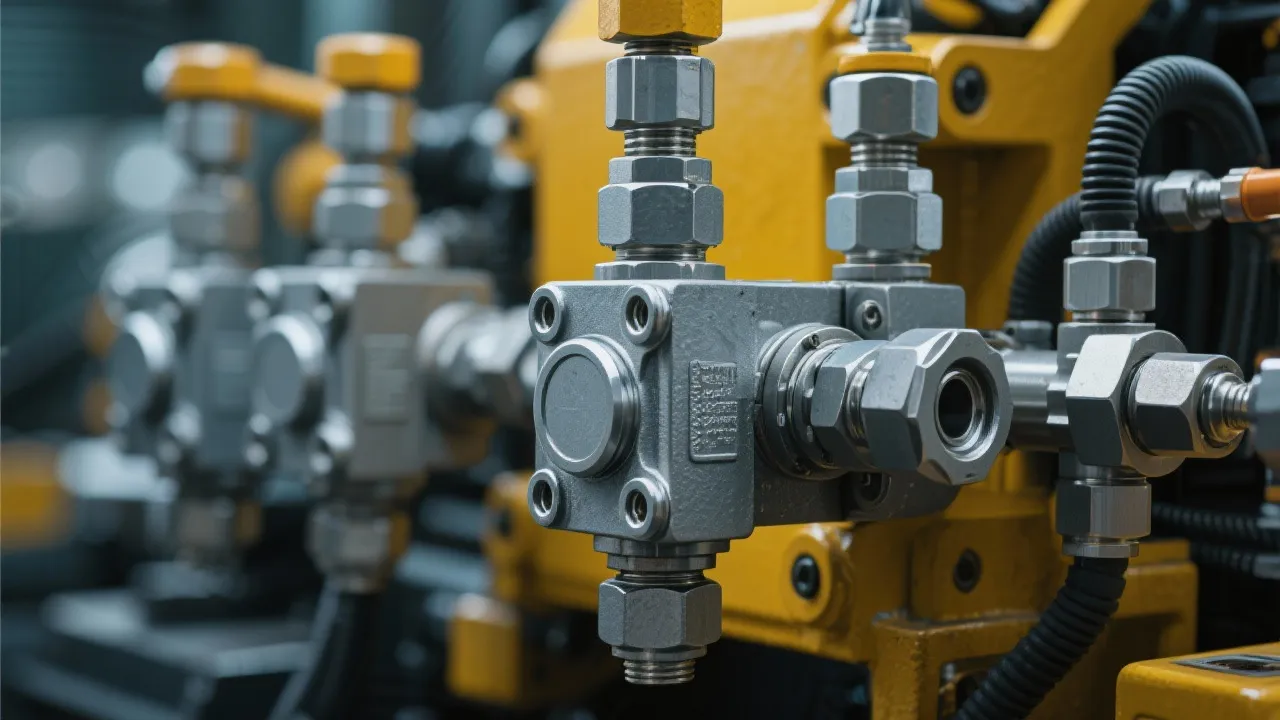

Rexroth Counterbalance Valves play a crucial role in hydraulic systems by controlling motion and ensuring safety. These valves, integral to maintaining system stability, prevent unintended movement by balancing pressure inconsistencies. Their precise engineering makes them indispensable in industries that rely on machinery, such as manufacturing and construction, ensuring smooth and controlled operations.

Rexroth Counterbalance Valves are pivotal components within hydraulic systems, renowned for their role in controlling, stabilizing, and enhancing system safety. As hydraulic systems become increasingly complex, counterbalance valves are fundamental in regulating pressure, thereby ensuring equipment functions effectively and safely. These valves are engineered to provide a controlled flow even in the event of pressure fluctuations, stress on the system, or abrupt changes in load conditions. Their operation is central to ensuring that heavy equipment remains manageable, allowing operators to maintain control even in demanding situations.

These valves are specifically designed to counteract potential problems related to uncontrolled movement within hydraulic systems. By balancing pressure discrepancies, Rexroth Counterbalance Valves effectively prevent unintended operation, which is crucial in maintaining safety standards and operational efficiency. This makes them invaluable in industries such as manufacturing, construction, and heavy machinery, where precise movement control is essential. Their functionality extends beyond mere operational control; they also contribute significantly to the longevity of the hydraulic system. By actively managing hydraulic pressure, they reduce wear and tear, thereby extending the service life of the machinery in which they are installed.

Rexroth Counterbalance Valves are engineered to accommodate varying pressure levels, providing reliable performance across diverse applications. Their construction typically involves durable materials designed to withstand high pressure and temperature variations. Features such as adjustable pressure settings and quick-response operation contribute to their widespread adoption in industrial applications. The valves can be designed with different flow characteristics to match an application’s specific needs, ensuring optimal performance. Additionally, many models incorporate features like internal or external pilot control options, which can enhance the responsiveness and flexibility of the system's operation.

Choosing the right counterbalance valve requires an understanding of several factors, including the specific application, the pressure and flow requirements, and compatibility with existing hydraulic systems. Evaluating these criteria ensures optimal performance and enhances the longevity of the system involved. Other considerations may include spatial constraints within the hydraulic system, environmental conditions such as exposure to corrosive elements or extreme temperatures, and maintenance requirements. Manufacturers often provide detailed specifications for their valves, helping engineers make informed decisions based on detailed operational scenarios.

| Attribute | Details |

|---|---|

| Pressure Range | Designs accommodate various pressure levels to ensure compatibility with multiple systems. |

| Material | Constructed with high-grade materials resistant to wear and extreme environments. |

| Adjustability | Features easy-to-adjust settings for precision control. |

| Flow Characteristics | Customizable flow rates to suit specific operational requirements. |

| Size Variants | Available in a range of sizes to fit various applications and space limitations. |

| Installation Type | Options for both inline and manifold mounting for flexibility in system design. |

| Response Time | Designed for quick response to changes in pressure and load conditions for enhanced control. |

The versatility of Rexroth Counterbalance Valves allows them to be integrated across numerous sectors. In manufacturing, these valves ensure the precise control of robotic arms and production lines. Tools and machinery that require exact movement, such as CNC machines and conveyors, benefit greatly from these valves, enhancing productivity and reducing the risk of mishaps. In construction, they aid in heavy lifting and material handling, providing stability even under irregular loads or movement. Cranes and forklifts equipped with counterbalance valves can perform tasks such as lifting and positioning heavy loads while maintaining safety and control, critical in busy construction environments.

In addition to manufacturing and construction, automotive assembly lines utilize these valves to maintain the safety and operational protocols essential when dealing with vehicles and machinery. Agricultural equipment, such as tractors and harvesters, also incorporates counterbalance valves to manage the weight and control of attachments, minimizing risks related to tipping and loss of control while operating on uneven terrain.

Moreover, in the renewable energy sector, especially in the operation of wind turbines and solar panel installations, counterbalance valves are crucial for stability under varying environmental conditions. They allow for precise adjustments to loads, enabling equipment to adapt dynamically to changes in weather and load distribution. This adaptability not only enhances operational efficiency but also ensures that safety protocols are met consistently.

Integrating these valves into existing systems may pose challenges such as adjusting to differing pressure ranges or ensuring compatibility with older machinery. Professional guidance and detailed system assessments are recommended to address these challenges effectively, ensuring seamless integration and performance optimization. One common challenge is the mismatch between the specifications of existing systems and those of the new counterbalance valves. Engineers must closely evaluate flow rates, pressure levels, and the overall design of the hydraulic system to ensure compatibility.

Another potential issue is the physical installation of the valves, particularly in compact or tightly designed machinery where space constraints can complicate the integration process. In such scenarios, selecting valves that are designed for easy installation or adjusting existing hydraulic layouts may be necessary to accommodate the new components. Engineers may also utilize custom fittings or adapters to achieve seamless connections within the hydraulic system.

Training and familiarization with the specific types of Rexroth Counterbalance Valves being utilized is essential for maintenance personnel and operators. Providing adequate training ensures not only optimal operation but also allows for the timely identification of issues that may arise during the operation of hydraulic systems. Furthermore, conducting regular maintenance checks and adopting predictive maintenance strategies can mitigate many integration problems, resulting in prolonged system life and performance efficiency.

Rexroth Counterbalance Valves are integral to enhancing the functionality, safety, and precision of hydraulic systems. Their engineering excellence supports industries by ensuring reliability and performance, ultimately contributing to technological advancement and industrial safety. As industries continue to evolve, with an increasing focus on automation and efficiency, the importance of reliable components like Rexroth Counterbalance Valves cannot be overstated.

Looking towards the future, advancements in valve technology may introduce features such as integrated smart controls that allow for real-time monitoring and adjustments remotely. Such innovations could further enhance operational efficiency, allowing for proactive management of hydraulic systems, boosting not only productivity but also safety standards across various industries. Ultimately, the role of counterbalance valves in hydraulic systems remains a pivotal area of development, mirroring the ongoing technological evolution within the sectors they serve.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!