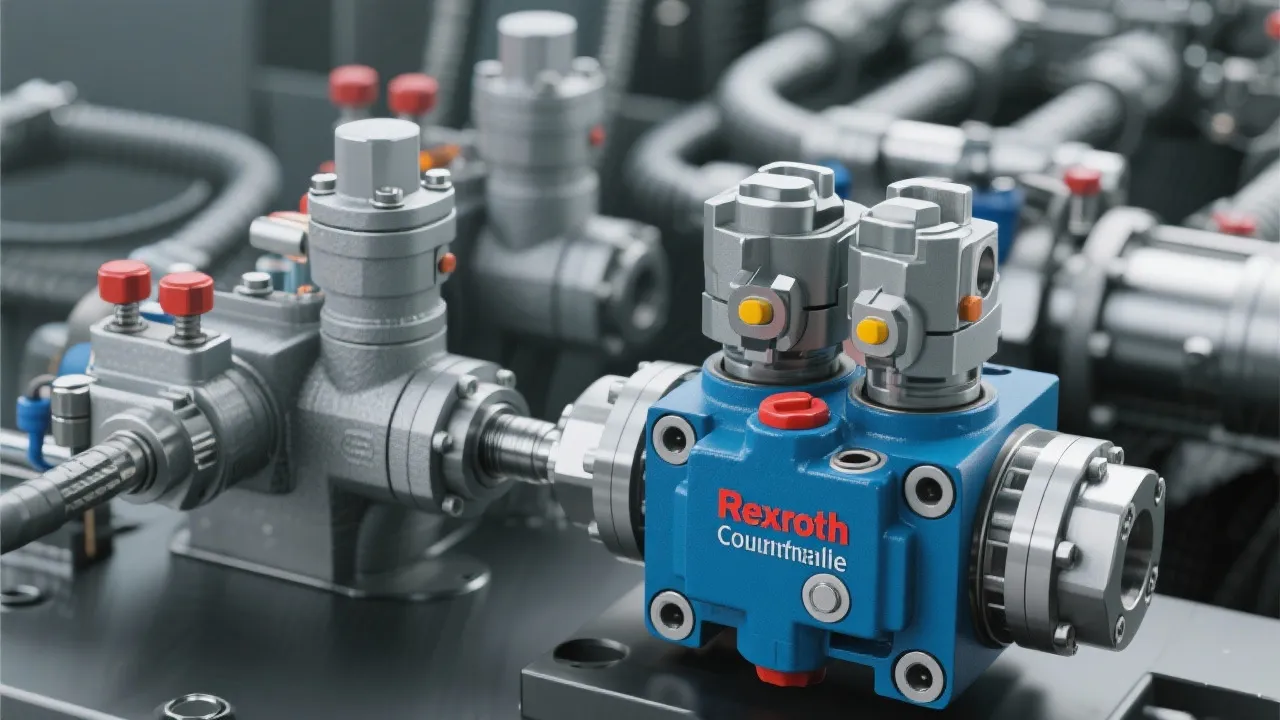

Rexroth Counterbalance Valves play a vital role in hydraulic systems by controlling the flow and maintaining stability during operations. They are essential in applications requiring precise motion control and substantial load management. Understanding these valves can significantly enhance system performance, offering benefits like reduced operational costs and improved safety.

Rexroth Counterbalance Valves are integral components in hydraulic systems, designed to regulate the flow and maintain the pressure of hydraulic fluid. These valves are paramount in applications where load holding, stability, and safety are critical. Their primary function is to balance the hydraulic loads, prevent system overload, and ensure smooth operation across various mechanical applications.

In hydraulic systems, the ability to manage and control forces is fundamental. Load handling in cranes, excavators, and material handling equipment requires precision under varying loads and pressures. Rexroth Counterbalance Valves excel in this regard, equipped with innovative technology designed to withstand the rigors of demanding industrial environments.

At the core of their operation, Rexroth Counterbalance Valves maintain a specific pressure in the system. This is crucial during the lowering of heavy loads to prevent a sudden drop or affordable fall. By controlling the fluid flow within the system, they ensure that machinery operates smoothly and efficiently. The counterbalance aspect is particularly vital in systems that regularly handle heavy-duty tasks or are prone to jerky, erratic movements.

When a hydraulic actuator, such as a cylinder or motor, is used to lift a load, the pressure generated within the hydraulic fluid is critical to maintain the load's position. Upon lowering the load, if the fluid were allowed to flow uncontrolled, the load could descend too rapidly, leading to catastrophic failure and potential injuries. The counterbalance valve regulates this fluid escape, allowing for a controlled lowering of the load, which mitigates such risks.

This technology is particularly evident in applications such as aerial work platforms, where the stability of the platform is incredibly essential. The abrupt drop of an elevated platform can have severe consequences - both in terms of safety for operators and equipment integrity. Rexroth Counterbalance Valves monitor the hydraulic pressures, ensuring safe descent speeds.

Rexroth Counterbalance Valves find applications across various industries, including construction, manufacturing, and automotive. In construction equipment, for instance, these valves are used to control the boom or arm of cranes, allowing for precise maneuvering of heavy loads. Similarly, in automotive systems, they manage hydraulic pressure to ensure stable suspension.

Specifically, in the construction industry, they are found on hydraulic excavators. The boom and stick—responsible for digging and lifting—rely on these valves to manage the descent of heavy loads. This ensures that, even during rapid retraction or extension, the load stays under control. This functionality not only aids in operational efficiency but also enhances the safety of the workforce around these machines.

In manufacturing, Rexroth Counterbalance Valves are critical in handling robotic arms and automated equipment, where precision and control over heavy components are paramount. They prevent equipment from falling unexpectedly during operations, allowing manufacturers to enhance their assembly line safety protocols. Such measures lead to increased productivity, as workers can operate without the fear of equipment mishaps.

The automotive sector also sees the need for precise hydraulic control in vehicle systems. For example, in the assembly of vehicles, hydraulic systems utilize counterbalance valves to manage the loads when hydraulic tools are employed. This ensures consistent application of force reducing the likelihood of damage during assembly.

Moreover, in the world of marine and offshore applications, stability is vital, especially for vessels that lift heavy equipment. The dynamic conditions of water require advanced hydraulic control, and this is where Rexroth Counterbalance Valves excel, maintaining stability under fluctuating loads and maintaining safe operational parameters.

Choosing the right Rexroth Counterbalance Valve involves understanding system requirements and dynamics. Experts recommend considering factors like load weight, system pressure, and operational environment. It’s not only about selecting a valve that can manage the specified pressure but also one that matches the fluid type and temperature ranges that will be encountered in operation.

Moreover, system designers must consider the specific application: for heavy-duty, continuous operations, a durable valve may be preferred, while lighter operations might allow for more affordable options. Consulting technical data and application guidelines provided by Rexroth can help in making an informed decision.

Regular maintenance, including checking for leaks and ensuring connections are secure, is essential for optimal performance. It’s advisable to follow a detailed maintenance plan that includes intervals for cleaning, inspection, and complete checks for performance metrics. Specialized maintenance services can be used to ensure that counterbalance valves are functioning at their best, inputting high-quality hydraulic fluids and ensuring any worn components are replaced timely.

In addition to physical maintenance, operators should be trained to understand the signs of valve malfunction. Issues such as unusual noises, slow response times, or unexpected load movements can signal that maintenance is overdue, and addressing these problems early can save significant costs related to equipment failure.

| Feature | Details |

|---|---|

| Max Pressure | Up to 420 bar |

| Flow Capacity | Up to 200 L/min |

| Temperature Range | -20°C to +80°C |

| Material | High-strength steel |

| Sealing Type | Dynamic sealing with high resistance to wear |

| Response Time | Less than 30 milliseconds |

| Weight | Varies based on size and specifications |

| Mounting Type | Flange and inline options available |

Q1: Why are Rexroth Counterbalance Valves crucial in hydraulic systems?

A1: These valves ensure safety, precision in motion control, and efficiency in systems handling heavy loads. They are designed to slow the descent of loads, providing stability and control under various operating conditions.

Q2: How often should Rexroth Counterbalance Valves be inspected?

A2: Regular inspection, ideally every 3 to 6 months, is recommended to ensure optimal functioning. However, higher usage or harsh operating conditions may necessitate more frequent checks.

Q3: Can these valves be integrated into existing systems?

A3: Yes, they are compatible with various hydraulic configurations, though professional guidance is advised for integration to ensure compatibility and optimal performance.

Q4: What common issues might arise with counterbalance valves?

A4: Common issues include leakage, sticking or jammed valves due to contamination, and improper calibration. Regular maintenance can help mitigate these problems by ensuring clean and correctly calibrated components.

Q5: What performance metrics should be monitored for counterbalance valves?

A5: It’s essential to monitor pressure drops, response times, and the overall integrity of hydraulic fluid levels. Any irregularities in these metrics can indicate potential valve issues.

Understanding the role and functionality of Rexroth Counterbalance Valves is pivotal for industries relying heavily on hydraulic systems. These components not only enhance the safety and efficiency of operations but also contribute to longer equipment life and reduced maintenance costs. As such, they represent a smart investment for any industry looking to optimize its hydraulic operations.

As technology continues to evolve, so too does the functionality and efficiency of hydraulic components like Rexroth Counterbalance Valves. Emerging trends such as integrated smart technologies can provide valuable data analytics about valve performance and hydraulic system health. This could lead to predictive maintenance strategies that allow companies to minimize downtime and maximize productivity.

Furthermore, industries must stay informed of new developments in hydraulic technology and regulatory standards that may affect the application of counterbalance valves. By staying up-to-date, organizations can remain competitive and ensure their systems operate at peak efficiency, contributing to safer work environments and better overall productivity.

As we move into a more automated future, the role of hydraulic components will continue to expand, pushing the boundaries of what is possible in engineering and design. Thus, investing in quality counterbalance valves becomes not just a matter of safety or efficiency, but also of future-proofing operations against the challenges of modern industrial demands.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!