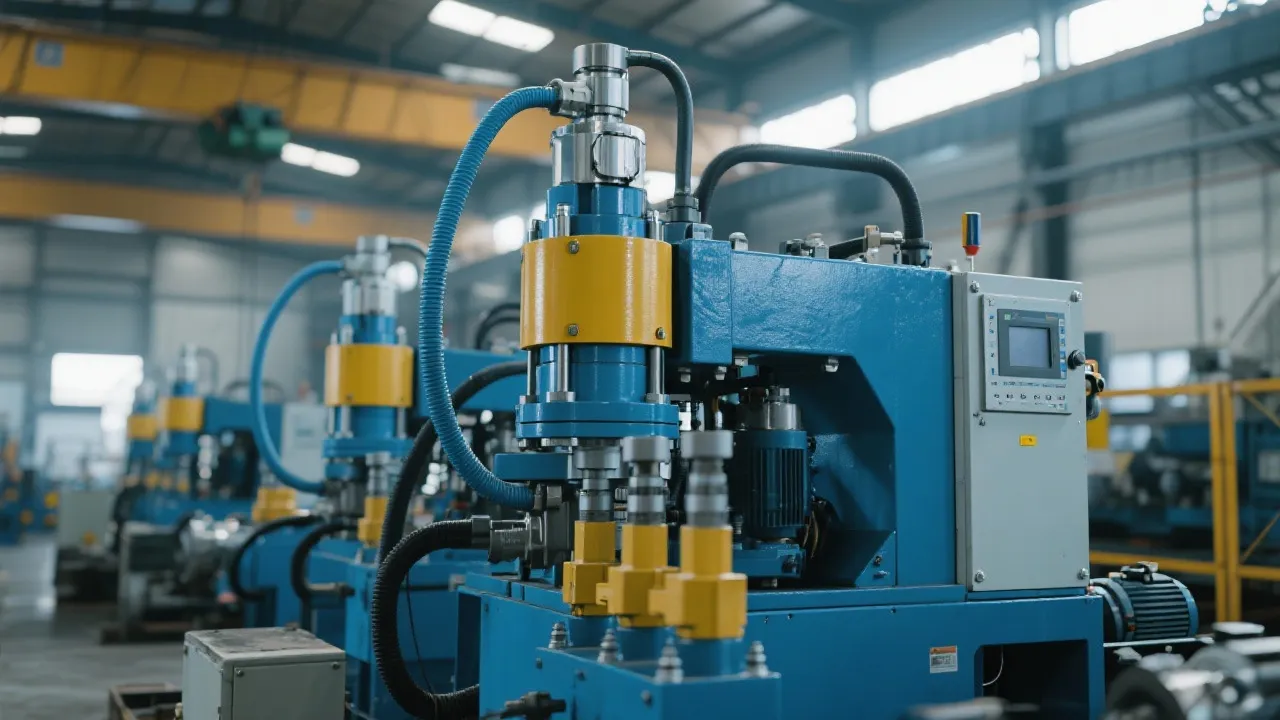

Rexroth Counterbalance Valves are vital components in hydraulic systems for regulating pressure and enhancing safety. Designed by Bosch Rexroth, these valves stabilize loads and prevent uncontrolled movements, often used in industrial and construction machinery. This article delves into their function, benefits, and proper maintenance, providing a comprehensive overview for industry professionals.

The Rexroth Counterbalance Valve is an essential component in modern hydraulic systems, known for its role in ensuring system stability and safety. These valves are engineered by Bosch Rexroth, a leader in industrial and mobile applications, to optimize performance across various heavy machinery. Their primary function is to control and stabilize the motion of loads, preventing affordable-fall or runaway movements, making them indispensable in construction, lifting, and material handling equipment. The technology behind these valves plays a pivotal role in enhancing operational safety and efficiency, catering to the demands of both operators and the environments in which they work.

Incorporating Rexroth Counterbalance Valves into hydraulic systems offers numerous advantages. They enhance the safety and reliability of equipment by preventing abrupt or unintentional movements, essential in operations involving heavy or awkward loads. Furthermore, these valves contribute to increased system efficiency by maintaining optimal pressure levels, reducing energy consumption and wear on components. The presence of these valves not only ensures the safety of the machinery but also augments the overall performance of the hydraulic system, promoting smoother operations.

Additionally, Rexroth Counterbalance Valves help in extending the life of the hydraulic system. By preventing pressure spikes and the resultant shock loading, they mitigate the risk of mechanical failure. Operators can rely on the controlled descent of loads, which minimizes the risk of accidents and mechanical failures that can arise from abrupt load shifts.

| Valve Type | Function | Application |

|---|---|---|

| Rexroth Counterbalance Valve | Holds and controls load pressure | Construction machinery, Cranes |

| Relief Valve | Protects system from overpressure | General hydraulic systems |

| Flow Control Valve | Regulates flow rate | Pumps and motors |

| Directional Control Valve | Directs hydraulic flow to the desired actuators | Robotics, Automated machinery |

By understanding the distinct functionalities of these valves, operators can make informed decisions regarding which type to integrate into their hydraulic systems. The combination of a Rexroth Counterbalance Valve with other valve types can lead to optimized system performance, providing a layered approach to hydraulic control.

Maintaining Rexroth Counterbalance Valves involves regular inspections and adherence to manufacturer guidelines. Key practices include:

In addition, operators should maintain a detailed record of maintenance activities. This documentation helps in tracking performance and identifying patterns that may signal impending issues. Establishing a routine maintenance schedule based on manufacturers' recommendations can prevent unexpected breakdowns and costly repairs. Utilizing technology, such as IoT sensors for real-time monitoring, can also greatly enhance maintenance practices by providing data on performance and early warning signs of potential failures.

Recent developments in the field of hydraulic components have led to the integration of advanced technologies into the design of Rexroth Counterbalance Valves. For instance, the incorporation of electronic controls and smart sensors into these valves represents a significant evolution in their functionality and efficiency. Smart technology in counterbalance valves allows for real-time monitoring and adjustments, leading to enhanced performance based on actual operational conditions.

Such advancements mean that operators can benefit from predictive maintenance, whereby potential failures are identified before they occur, reducing downtime and repair costs. Furthermore, advanced counterbalance valves can adapt their response based on load conditions, leading to more efficient energy use and improved response times. As hydraulic systems continue to evolve with the incorporation of Industry 4.0 principles, Rexroth Counterbalance Valves will play a crucial role in the future of automated hydraulic systems.

The primary purpose is to manage the load pressure, ensuring the stability and safety of hydraulic systems while allowing for controlled movement of heavy loads.

Routine checks are advisable every six months, with comprehensive maintenance recommended annually. However, this frequency may vary based on usage intensity and operational conditions.

Yes, they are versatile and can be integrated into various hydraulic systems easily, accommodating both new installations and retrofits of existing systems.

Common signs include unexpected load drops, system pressure irregularities, and audible leaks. If operators notice slower response times or inconsistent load control, these could also indicate the need for inspection.

Yes, these valves can be designed to withstand extreme conditions, such as high temperatures and exposure to corrosive substances, depending on the materials used and design specifications.

Installation requirements typically include ensuring proper orientation, adequate space for maintenance, and aligning the valve with system hydraulic circuits while ensuring there are no pressure drops or flow interruptions in the system.

The integration of Rexroth Counterbalance Valves into hydraulic systems represents an investment in safety, efficiency, and reliability. By understanding their function and maintaining them properly, industries can significantly enhance their operational effectiveness, reduce maintenance costs, and improve safety standards. As versatile and reliable components, these valves are a staple in ensuring optimal hydraulic system performance across various industrial applications.

With ongoing advancements in hydraulic technology, the future seems promising for the development of even more sophisticated counterbalance systems. As manufacturers continue to innovate, we can expect to see enhanced features that support sustainable practices and energy efficiency. By investing in these technological advancements, companies can position themselves at the forefront of industrial productivity and safety. Thus, Rexroth Counterbalance Valves not only serve a critical role in present-day applications but also pave the way for future advancements in hydraulic engineering.

The application of Rexroth Counterbalance Valves can be observed across a myriad of industries, demonstrating their adaptability and importance in various sectors. Below are a few notable areas where these valves play a pivotal role:

In the construction industry, where heavy equipment is frequently in use, Rexroth Counterbalance Valves ensure that cranes and excavators maintain stability during operations. These valves help control the descent of loads, allowing workers to handle materials with greater precision and safety. Furthermore, in high-rise construction, where lifting loads to great heights is routine, the risk of free-fall accidents is a critical concern. The integration of counterbalance valves mitigates these risks significantly by providing reliable load control.

Material handling systems, including lift trucks and automated guided vehicles, rely on Rexroth Counterbalance Valves for efficient and safe operations. These valves enable operators to handle heavy loads without the concern of load drops or instability. In warehouses and distribution centers, where time and accuracy are paramount, the presence of these valves contributes to streamlined operations and improved safety protocols.

In agriculture, the use of hydraulic systems in tractors and harvesters is critical for effective operations. Rexroth Counterbalance Valves assist in managing the lifting and lowering of heavy agricultural implements, ensuring that they operate safely without unexpected load shifts. This is particularly essential when dealing with uneven terrain, where stability is critical to avoid accidents and machinery damage.

Within automotive manufacturing, Rexroth Counterbalance Valves are employed in assembly lines where precision is required for lifting and placing components. By ensuring accurate control over load movements, these valves help maintain efficiency in assembly processes, reduce the risk of component damage, and improve workplace safety.

The future of Rexroth Counterbalance Valves looks promising as industries continue to evolve towards smarter systems. The integration of digital technology with hydraulic systems is expected to increase the functionality of these valves significantly. As companies are striving for Industry 4.0, counterbalance valves are likely to feature IoT capabilities, allowing them to send diagnostic data directly to operators.

This will support proactive maintenance strategies, whereby potential issues can be flagged for attention before they develop into significant problems. Such advancements will not only improve the reliability of hydraulic systems but will also contribute to overall operational efficiency.

Furthermore, the push for sustainability in industrial applications implies that future developments may focus on creating more energy-efficient counterbalance valves. Innovations aimed at reducing energy consumption while maintaining performance standards will take center stage, aligning with global sustainability initiatives.

In conclusion, Rexroth Counterbalance Valves stand out as key players in the hydraulic systems of today and are positioned to adapt to future market demands. Their continuous evolution will reflect the broader trends in the hydraulic and industrial landscape, providing a foundation for innovation and safety in various applications.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!