Eaton Proportional Valves are a crucial component in modern hydraulic systems, offering precision and control in fluid power applications. These valves regulate flow or pressure by converting a controlled input signal into mechanical motion. Eaton's innovation in valve technology supports various industries, including industrial machinery and aerospace, reflecting their global reach and engineering excellence.

The Eaton Proportional Valve is integral to controlling hydraulic and pneumatic systems in various industries. These valves are designed to regulate fluid flow and pressure with remarkable precision, significantly enhancing the performance and efficiency of complex machinery. From industrial machinery to aerospace applications, Eaton's valves are renowned for their reliability and advanced engineering. In today’s competitive landscape, the need for precision in hydraulic actuation systems cannot be overstated, as it directly impacts operational efficiency and productivity. Eaton has consistently pushed the envelope of innovation to ensure that their proportional valves remain at the forefront of hydraulic technology.

Eaton Proportional Valves are characterized by their ability to provide fine control over hydraulic systems. Their advantages include improved system responsiveness and energy efficiency. These valves can convert an electronic signal into a proportional hydraulic output, allowing for more precise control compared to traditional on/off valves. The significance of this mechanism cannot be underestimated as it allows operators to achieve desired outcomes with minimal waste. Business operations benefit considerably from such accuracy, which not only reduces wastage but also improves overall productivity. For example, in manufacturing applications, the precise flow control offered by Eaton valves can lead to significant reductions in energy consumption, translating into cost savings and environmental benefits.

The versatility of Eaton Proportional Valves finds applications across a multitude of settings. In the industrial sector, they are used to manage the hydraulic systems of production equipment, enhancing the precision of tools like presses, hoists, and milling machines. Each type of machinery benefits from the ability to maintain speed and force with high accuracy, which is vital for ensuring the quality of manufactured goods.

Alongside industrial uses, Eaton Proportional Valves are critical to aerospace applications, where they control the movement and positions of flight control surfaces such as elevators, ailerons, and flaps. Here, they contribute significantly to safety and performance during flight operations. The reliability of Eaton valves in extreme conditions—such as high altitudes and varying temperatures—ensures that they perform optimally when stakes are highest.

In addition to industrial and aerospace applications, Eaton valves are also gaining traction in the field of mobile machinery, including construction and agricultural equipment. These applications require robust and powerful valve systems that can handle the demands of fluctuating loads and variable flow conditions, making Eaton Proportional Valves a preferred choice among manufacturers of such equipment.

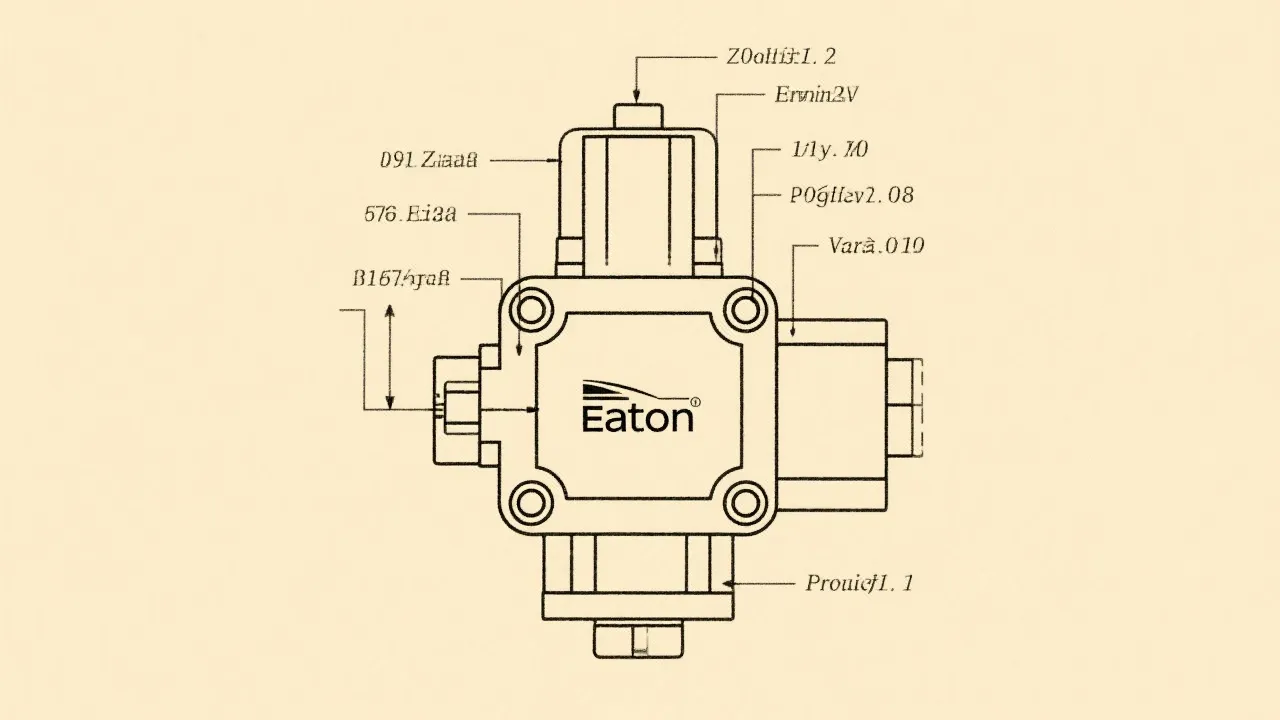

Eaton Proportional Valves are available in various configurations to suit specific applications. Understanding the technical specifications is crucial for selecting the appropriate valve for a given application. Key specifications include pressure ratings, flow capacity, response time, and temperature range. Each specification plays a pivotal role in determining how well a valve will integrate into a hydraulic system.

Pressure ratings indicate the maximum pressure that the valve can withstand, which is essential for ensuring safety and operational reliability. Flow capacity measures the volume of fluid that can pass through the valve over time, impacting the speed and efficiency of the hydraulic system. The response time of a valve is a critical factor that influences the system’s performance, particularly when quick adjustments are necessary. Finally, understanding the temperature range is vital for applications exposed to extreme environmental conditions, which could otherwise compromise valve performance.

Eaton provides comprehensive guides and datasheets on each valve model to aid engineers in making informed decisions. Additional customization options allow for greater adaptability, especially in specialized applications where standard configurations may not suffice.

| Specification | Details |

|---|---|

| Pressure Rating | Up to 350 bar |

| Flow Capacity | Up to 1000 L/min |

| Response Time | Less than 30 ms |

| Temperature Range | -30°C to 100°C |

| Electrical Input | 10-30 VDC |

| Control Type | Proportional |

| Size Options | Various sizes available, tailored to fit multiple applications |

The installation of Eaton Proportional Valves requires a meticulous approach to ensure that all connections are secure and the system calibration is precise. Proper installation is key to maximizing the valve's performance and ensuring it operates within the specified parameters. Engineers should conduct thorough system checks and follow best practices during installation to prevent future complications.

Routine maintenance of Eaton Proportional Valves is essential for upholding operational integrity and extending the component lifespan. This includes regular checks for leaks, monitoring signal functionality, and verifying that the equipment is operating within the appropriate temperature and pressure ranges. Users should maintain a schedule for these checks and routinely service the valves to replace worn parts and minimize the risk of unexpected failures.

The integration of monitoring systems into the hydraulic circuit can also provide real-time data on the performance of the valves, allowing for preemptive maintenance. Advanced solutions like predictive maintenance software, which uses data analytics to forecast potential issues before they arise, can be invaluable for maintaining system uptime.

It is essential to train maintenance personnel in the specific maintenance requirements for Eaton Proportional Valves. The intricacies of these valves and their control mechanisms demand that technicians are familiar with electrical components as well as hydraulic systems. Having a well-trained team will result in higher efficiency in maintenance tasks and reduce the likelihood of errors during servicing.

While Eaton valves are known for their durability, occasional issues such as erratic control signals or pressure drops can occur. Regular inspections and using diagnostic tools to assess the electronic control signals can help identify and rectify such issues promptly. Some common problems that users can encounter include:

Eaton provides excellent after-sale support and resources such as troubleshooting manuals, instructional videos, and customer service contacts to resolve any problems effectively. Utilizing these resources can facilitate fast problem resolution and help maintain optimal system performance. Additionally, building a relationship with Eaton's technical support team can provide users with valuable insights into advanced troubleshooting techniques that may not be readily apparent.

To further illustrate the significance of Eaton Proportional Valves, examining case studies from industries that have integrated these valves into their operations offers valuable insights. By analyzing real-world scenarios, we can see measurable improvements in system efficiency, safety, and reliability that have resulted from utilizing Eaton's advanced engineering solutions.

In the automotive manufacturing industry, a leading car manufacturer implemented Eaton Proportional Valves into their robotic assembly lines. The incorporation of these valves allowed for the precise control of hydraulic actuators that move heavy components of vehicles. This resulted in a 20% increase in assembly speed and a substantial reduction in energy consumption by 15%. The enhanced responsiveness of the valves facilitated quicker adjustments to assembly processes, enabling the manufacturer to meet rising demand without compromising quality.

In the agricultural sector, a prominent tractor manufacturer integrated Eaton Proportional Valves in their hydraulic system designed for tillage tools. The new system allowed for better flow modulation during tilling operations, improving soil penetration and reducing fuel consumption. As a result, farmers using these tractors reported that they could cover the same area in less time, translating to increased productivity for their agricultural activities. The feedback emphasized the environmental impact of reduced emissions, representing a win-win situation for both the manufacturer and the end-users.

Moreover, in the aerospace industry, an aircraft manufacturer utilized Eaton Proportional Valves in their flight control systems. The precise control over the ailerons and wing flaps contributed to improved aerodynamic performance, enhancing flight stability and fuel efficiency. Testing revealed that the combination of improved control and lighter materials resulted in a notable reduction in overall aircraft weight, leading to a significant enhancement in flight range. Safety was also bolstered, as the valves demonstrated reliability in extreme conditions, consistent with the demanding standards of the aerospace sector.

In conclusion, Eaton Proportional Valves stand out as an exceptional choice for modern hydraulic systems requiring precision, reliability, and efficiency. Their application across diverse industries underscores their adaptability and the technological advancements that Eaton continues to contribute to the market. By meeting the stringent demands of various sectors with a focus on innovative design, Eaton has positioned its valves as essential components for businesses aiming to optimize performance and improve productivity.

As industries evolve and the demand for efficiency intensifies, incorporating solutions like Eaton Proportional Valves is vital for companies looking to maintain competitive advantages. The design and engineering behind these valves not only fulfill current needs but also anticipate future challenges in hydraulic engineering and automation. Overall, while Eaton Proportional Valves are rooted in advanced technology, their true value lies in the tangible benefits they deliver to systems, operators, and businesses alike.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!