Stauff Filters are integral components in industrial systems, offering reliable filtration solutions crucial for maintaining fluid cleanliness in hydraulic and lubrication applications. These filters are critical for ensuring efficiency, reducing wear, and extending the lifespan of equipment. This article delves into the importance of Stauff Filters, their various applications, and industry insights on leveraging these components effectively.

The realm of industrial systems and machinery heavily relies on components that ensure operational efficiency and longevity. Among these components, Stauff Filters stand out as pivotal elements in maintaining fluid cleanliness across hydraulic and lubrication systems. These filters are engineered to remove contaminants that could potentially cause wear and tear, ensuring seamless operation and preventing costly equipment failures.

Contamination in fluids, whether from dust, dirt, or internal wear particles, poses a significant risk to the operational performance of machinery. Such contaminants can lead to erosion, clogging, and breakdown of essential components, which in turn can cause unscheduled downtimes and expensive repairs. Therefore, the adoption of high-quality filtration systems, like those offered by Stauff, is crucial for industries relying on hydraulic and lubrication systems.

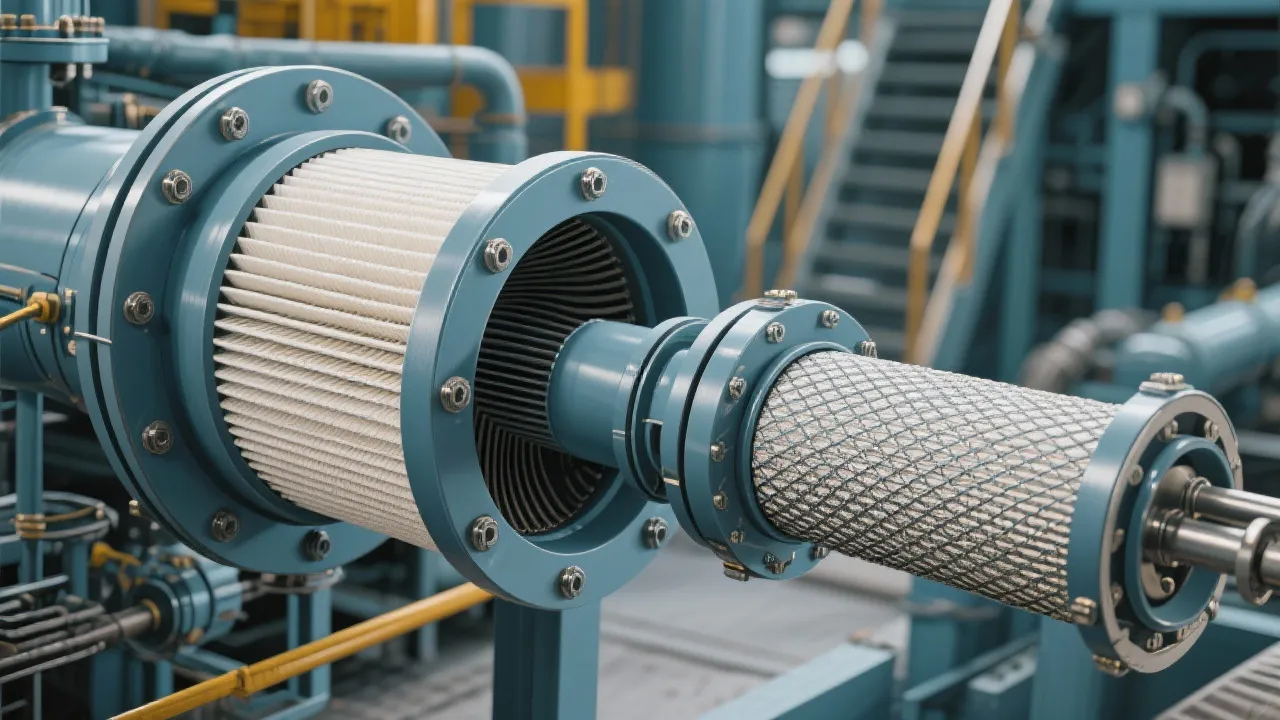

Stauff Filters are celebrated for their high filtration efficiency and robust construction, tailored to handle diverse applications ranging from simple machinery to complex industrial systems. They are particularly renowned for their ability to reduce particle contamination within fluids, thereby safeguarding components and enhancing system reliability.

Beyond basic filtration, the functionality encompassed within each design serves broader operational roles. By integrating finely engineered filtration solutions, Stauff Filters contribute to maintaining optimal viscosity levels within hydraulic systems, leading to enhanced energy efficiency. The filters are designed to ensure the minimal flow resistance, which allows the systems to operate smoothly without excessive energy consumption or pump strain.

Stauff offers a diverse range of filter types, each crafted to meet specific needs within industrial processes. These include spin-on filters, suction filters, return line filters, and pressure filters. Each type has distinct characteristics tailored to optimize filtration in various settings.

Understanding the different types of Stauff Filters is critical for engineers and technicians working across varying industrial landscapes. For instance:

| Filter Type | Application | Key Features |

|---|---|---|

| Spin-On Filters | Simple system integration | Easy to replace; suitable for various fluids |

| Suction Filters | Before the pump | Protects pumps from contaminants |

| Return Line Filters | Post-system filtration | Ensures clean fluids return to tank |

| Pressure Filters | High-pressure systems | Handles higher contamination loads |

Choosing the right Stauff Filter involves assessing several factors such as system requirements, fluid type, and operational conditions. It is crucial to ensure that the selected filter matches the pressure and flow specifications of the system to avoid functionality issues.

Moreover, understanding the specific environmental conditions where the filters will be operating can further enhance the effectiveness of the filtration system. For example, filters operating in colder climates might require different material compositions to maintain integrity under varying temperatures.

Stauff Filters are utilized across various industries, including construction, transportation, manufacturing, and energy. Their reliability and performance in filtering hydraulic fluids and lubricants are well-recognized, making them an ideal choice for critical applications in heavy machinery, industrial manufacturing, and beyond.

As industrial machinery continues to evolve, new applications and methodologies emerge that further amplify the importance of maintaining fluid cleanliness. The advent of technologies such as IoT-driven monitoring systems has allowed the real-time observation of filter performance and fluid condition, leading to proactive maintenance and reduced operational risks.

Q: What maintenance is required for Stauff Filters?

A: Regular inspection and timely replacement of filter elements are essential to maintain performance. Establishing a maintenance schedule helps ensure that the filters function optimally and can significantly extend the lifespan of your equipment.

Q: How often should Stauff Filters be replaced?

A: Replacement intervals vary based on system conditions; it's recommended to follow manufacturer guidelines and conduct routine checks. Factors such as operating environment, fluid quality, and contamination levels should all influence these intervals.

Q: Can Stauff Filters be customized?

A: Yes, Stauff offers customization options to meet specific industrial needs and specifications. Custom filters can be designed to accommodate unique operational requirements, thereby enhancing the filtration process for specialized applications.

Q: How can I monitor the performance of Stauff Filters?

A: Employing diagnostic tools or monitoring systems can help track the filter's performance, alerting operators to any required maintenance and ensuring that the system remains efficient. These tools can provide insights into fluid cleanliness and help detect changes in pressure or flow rates that may indicate filter load and effectiveness.

Q: Are there any environmental considerations with Stauff Filters?

A: Yes, selecting filters made from environmentally friendly materials and ensuring proper disposal of filters and contaminants helps mitigate environmental impacts. Moreover, regular maintenance of filtration systems contributes to overall sustainability by reducing waste and promoting the longevity of machinery.

In conclusion, Stauff Filters play an indispensable role in ensuring the efficiency and reliability of industrial systems. By carefully selecting and maintaining these filters, businesses can achieve significant improvements in operational performance and longevity, underscoring the critical nature of these components in industrial applications. The long-term benefits of utilizing high-quality filtration extend throughout the lifecycle of machinery, ultimately leading to cost savings, enhanced productivity, and improved environmental compliance.

The expanding realm of industrial automation will continue to highlight the necessity for high-performance filtration systems. As machinery and processes become increasingly sophisticated, the need to protect these investments with robust filtration solutions like Stauff Filters will only intensify. Investing in reliable filtration technology is an investment in the future of operational excellence and equipment longevity.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!