Stauff Filters are renowned in the industrial sector for their efficiency in hydraulic and lubrication system filtration. Originating from Stauff's commitment to quality, these filters improve system lifespan, reduce downtime, and are integral in maintaining operational efficiency across various applications.

In the realm of industrial filtration, Stauff Filters stand out as a cornerstone of performance and reliability. Used extensively in hydraulic and lubrication systems, these filters are designed to ensure that systems operate smoothly, minimizing wear and tear, and enhancing the longevity of machinery. With a commitment to innovation and quality, Stauff has established itself as a leader in the filtration market, providing solutions that adapt to the ever-changing demands of various industries. Their filters cater to an extensive range of applications, demonstrating remarkable flexibility and effectiveness in maintaining system integrity across diverse operational environments.

Filtration is a vital process in numerous industries, essential for the upkeep and efficiency of machinery. Contaminants such as particles of metal, rubber, dirt, and water can wreak havoc on system components if not properly managed. Stauff Filters address these concerns by effectively trapping impurities and ensuring that only clean fluid circulates through the system. These contaminants can lead to increased wear and failure of critical components, resulting in costly repairs and downtime. Consequently, the importance of utilizing high-quality filtration systems cannot be overstated; it directly correlates with the reliability and efficiency of machinery and equipment.

Understanding the significance of effective filtration also brings to light the disruptive impact of environmental factors. For instance, in applications exposed to extreme temperatures, high humidity, or chemical exposure, the likelihood of contaminants affecting system purity increases dramatically. Implementing Stauff Filters mitigates these risks by utilizing specialized materials and technologies designed to endure the most demanding conditions. This dedication to quality not only protects machinery but also enhances overall operational efficiency, contributing to a seamless production process.

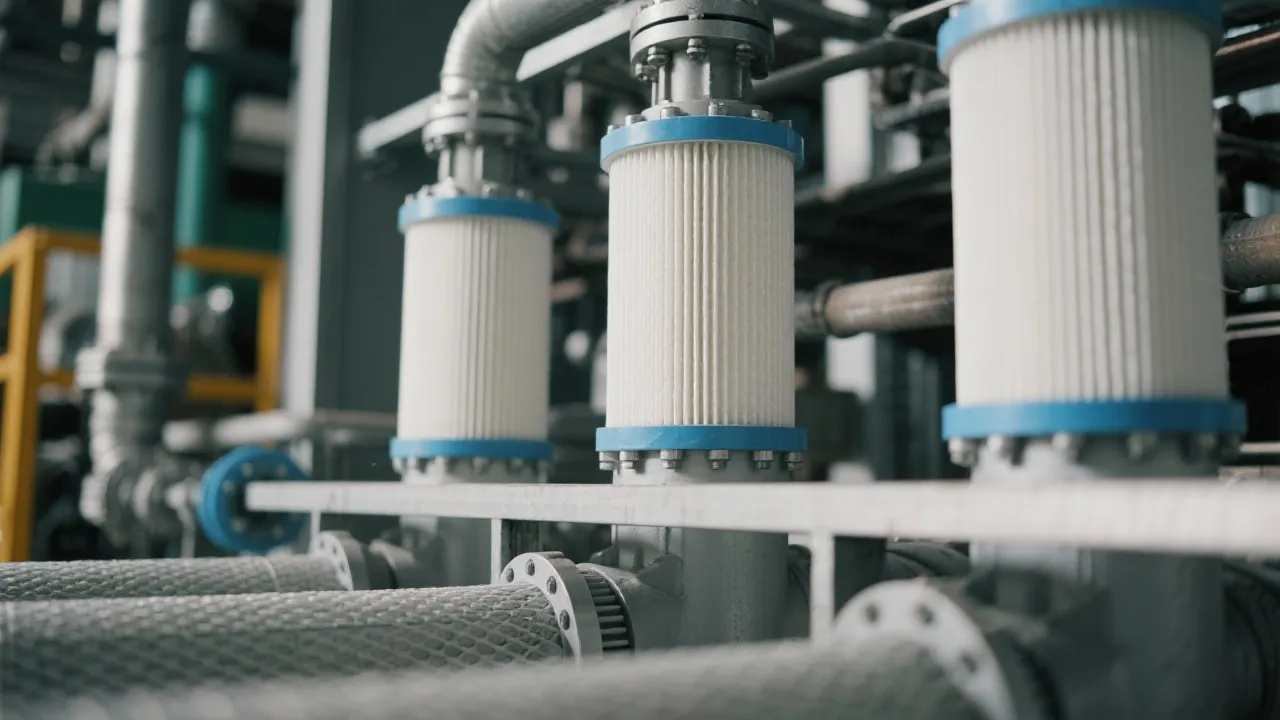

Stauff Filters incorporate advanced materials and design to maximize filtration efficiency. The use of sophisticated filter media and robust construction materials ensures that they withstand harsh operating environments while offering peak performance. These filters are designed with consideration of various factors like flow rate, pressure, and temperature to suit a wide array of industrial applications. Notably, the filter media often includes multi-layer designs that capture particles of varying sizes, including fine particulates that could otherwise compromise system performance.

Moreover, Stauff Filters leverage cutting-edge technology such as pleated filter designs, which increase surface area and improve the dirt-holding capacity of the filter. This design enhancement reduces the frequency of filter changes and minimizes pressure losses, thereby maintaining flow rates during operation. Additionally, many models are equipped with visual indicators that signal when maintenance is required, allowing for proactive management of the filtration system. Such innovations highlight Stauff’s commitment to integrating modern engineering techniques to enhance reliability and user convenience.

Choosing the right filtration system is paramount in maintaining system efficiency and reducing operational costs. Stauff Filters offer a range of benefits including enhanced protection against contamination, which directly translates to reduced downtime and maintenance costs. This, alongside their customized solutions and variety of filtration options, makes them a preferred choice among industry professionals. The extensive selection of filters allows users to find the perfect match for their specific operational requirements, ensuring that every system functions at its optimum level.

Furthermore, Stauff Filters are backed by a global network of expertise and service support. Customers benefit not only from high-quality products but also from access to knowledgeable professionals who can assist with the design and implementation of effective filtration solutions tailored to individual needs. The company’s dedication to customer support is a testament to its commitment to quality and reliability, providing users with peace of mind throughout the lifecycle of their filtration systems.

Stauff Filters are versatile, finding applications in sectors such as manufacturing, aerospace, agriculture, and energy. In manufacturing, they can be pivotal in metalworking and milling operations where hydraulic machinery is common. These filters play a critical role in keeping equipment running smoothly by preventing particles from causing damage to expensive components. The same is true in the aerospace industry, where the stringent requirements for hydraulic systems make Stauff Filters invaluable for maintaining system integrity and performance.

The agricultural sector benefits greatly from Stauff Filters as well, particularly in equipment used for irrigation and crop management. Clean hydraulic fluid is essential for the efficient operation of tractors and harvesters, ensuring that these machines can perform their functions without unnecessary interruptions. In energy production, especially in sectors such as oil and gas, the reliability of filtration solutions is non-negotiable. Here, Stauff Filters help to maintain high levels of system performance, thereby supporting the overall safety and efficiency of energy operations.

Stauff has also made significant inroads into the renewable energy sector with filtration solutions tailored for wind and solar power applications. These systems require specific filtration technologies to deal with the unique challenges presented by renewable energy sources, such as variable operating conditions and the potential for diverse contaminants. By providing advanced filtration systems adapted to these environments, Stauff plays a pivotal role in promoting sustainability while boosting productivity in green energy initiatives.

| Feature | Stauff Filters | Competitor A | Competitor B |

|---|---|---|---|

| Performance | High filtration efficiency with minimal pressure drop | Moderate efficiency with higher pressure drop | Varies, often less efficient in similar conditions |

| Durability | Constructed with high-end materials for longevity | Standard materials; slightly reduced lifespan | Variable, dependent on the model |

| Cost-effectiveness | Optimal performance/cost ratio | Moderate; higher good operational cost | Lower initial cost, higher maintenance expenses |

| Customization | Yes, tailored to specific industrial needs | Limited customization available | Varies by model and manufacturer |

The proper installation and maintenance of Stauff Filters are crucial to their performance. Installation should follow all specifications set by Stauff to ensure optimal functionality. Regular maintenance, including scheduled inspections and replacements of filter elements, helps in maintaining system efficiency and avoiding unexpected downtimes. Adhering to manufacturer recommendations regarding maintenance schedules will ensure that filters operate at peak performance, contributing to long-term reliability.

It's essential to keep a record of maintenance activities, as this documentation can help identify patterns regarding when filters typically require replacement or if specific issues arise consistently during operation. Implementing a preventive maintenance program that includes routine checks of filter conditions, visual inspections, and analyses of system performance can greatly enhance the working life of equipment and filters alike.

Additionally, operators should be well-trained in identifying the signs of filter failure. These signs may include unusual noises from machinery, unexpected drops in pressure, or visible leaks in the system. Prompt addressing of these indicators can prevent larger, more costly failures and maintain operational continuity. A rigorous approach to installation and maintenance goes hand-in-hand with optimal system performance, ensuring all components work in concert to produce desirable results.

Stauff Filters provide enhanced system reliability through superior contaminant removal, leading to extended equipment life and reduced maintenance costs. Their ability to capture a wide range of impurities translates to operational efficiency, thus reducing the frequency of costly repairs due to contamination-related failures.

By effectively filtering out contaminants, Stauff Filters decrease the chances of system failure and maintain optimal equipment performance, ensuring smooth and efficient operations. The reduction of potential contaminants not only protects machinery but also promotes consistent operational output, enhancing productivity over time.

Yes, Stauff offers customization options to cater to various industrial requirements, ensuring that each filter system meets specific operational demands. This customization extends to filter sizing, media type, and housing design, allowing businesses to tailor solutions exactly to their operational environment.

The lifespan of Stauff Filters can vary based on factors such as application type, environmental conditions, and contaminants' nature. However, with proper maintenance and regular inspections, these filters can last significantly longer than standard alternatives, contributing to lower overall operational costs.

Replacement and servicing frequency depend on several factors, including the specific application, system load, and type of contaminants present. Generally, it is advisable to follow the maintenance schedule provided by Stauff, which recommends regular checks and timely replacements to avoid system failures.

In conclusion, the implementation of Stauff Filters in industrial systems is a strategic investment towards achieving higher efficiency, durability, and cost savings. Stauff Filters not only excel in filtration capabilities but also demonstrate a commitment to quality and innovation that fits within the evolving landscape of industrial practices. As industries evolve, the demand for reliable and advanced filtration solutions continues to rise, solidifying the importance of equipment like Stauff Filters in maintaining operational standards. The proactive approach to maintenance and the emphasis on tailored solutions ensure that Stauff Filters remain at the forefront of industrial filtration technology, paving the way for a more efficient and sustainable future in manufacturing and beyond.

Throughout their journey in the industrial sector, organizations are encouraged to revisit their filtration strategies regularly, evaluating whether their current solutions meet the evolving requirements of their operations. By choosing Stauff Filters, businesses are not only investing in top-tier filtration technology but also ensuring that they future-proof their operations against the challenges posed by contamination and wear. Continuous improvement in filtration practices will ultimately lead to enhanced machinery performance and lower operational costs, fostering a more competitive edge in today's fast-paced market.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!