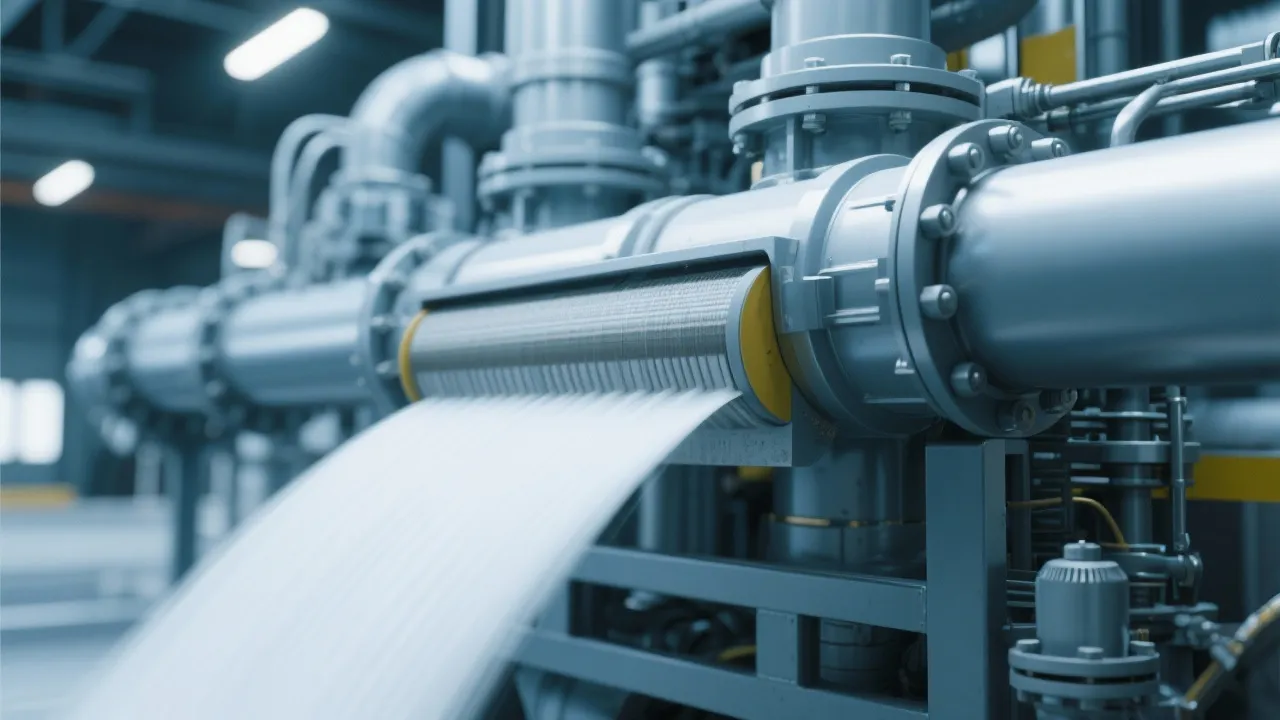

This comprehensive guide delves into the integral role of the Stauff Filter in industrial applications. Commonly utilized for hydraulic and lubrication systems, Stauff Filters are crucial for maintaining system efficiency and reliability. Known for their robust design and advanced filtration capabilities, these filters play a pivotal role in optimizing machinery performance by ensuring clean fluid operations.

The Stauff Filter has become an essential component in modern industrial applications, particularly within hydraulic and lubrication systems. These systems require precise and reliable filtration to ensure optimal performance and longevity. With machinery increasingly reliant on clean fluid operations, the Stauff Filter stands out for its durability and advanced filtration capabilities. This growing reliance on high-efficiency filtration is not merely a trend; it reflects an industry-wide push towards reliability and operational excellence that cannot be overlooked.

Stauff Filters are designed to remove contaminants from fluids efficiently, thereby prolonging the life of equipment and reducing the risk of breakdowns. These filters are engineered with innovative materials and structures that allow them to capture debris, particles, and other impurities, ensuring that the fluid running through machinery remains pristine. The design often incorporates features like multiple stages of filtration, allowing for the separation of particles of varying sizes, which further enhances their performance. Moreover, the filtration media used in Stauff Filters is formulated to withstand high pressures and challenging operating conditions, ensuring reliable performance in demanding environments.

The versatility of Stauff Filters is evident in their widespread application across various sectors, from automotive to marine engineering, construction to agriculture. In each of these industries, maintaining the integrity of hydraulic and lubrication systems is paramount. For example, in the automotive industry, Stauff Filters play a critical role in ensuring that hydraulic brake and steering systems function correctly, improving overall vehicle safety and operational reliability. In marine applications, these filters protect vital systems against seawater intrusion and other corrosive elements, guaranteeing the efficiency of vessels operating in harsh environments.

Furthermore, in construction, heavy machinery such as excavators and cranes significantly benefit from Stauff Filters. These machines operate under strenuous conditions where the hydraulic systems can easily become contaminated with dirt and debris, leading to premature wear and potential failures. Regular use of Stauff Filters can mitigate these risks, promoting smoother operation and reducing downtime. In agriculture, equipment such as tractors and harvesters also require reliable filtration systems to maintain performance. The efficacy of Stauff Filters in such diverse applications speaks volumes about their adaptability and importance across industries.

| Feature | Stauff Filter | Competitor A | Competitor B |

|---|---|---|---|

| Filtration Efficiency | High | Moderate | High |

| Durability | Robust | Standard | Robust |

| Cost | Moderate | Low | High |

| Maintenance Frequency | Low | High | Moderate |

| Customization Options | Available | Limited | Unavailable |

In evaluating these features, it becomes clear that while the initial investment in Stauff Filters may be moderate, the long-term advantages far outweigh the costs often associated with competitors. Not only does Stauff maintain a high standard of filtration efficiency and durability, but it also excels in providing maintenance solutions that ensure minimal operational disruption.

Stauff Filters are compatible with a wide range of fluids, including oils and lubricants, ensuring versatility in application. They are engineered to accommodate both low-viscosity thin liquids as well as thicker substances, making them a universal solution for various industrial requirements.

Replacement intervals depend on the specific application and operating conditions but generally follow the manufacturer's guidelines for top results. Factors such as the level of contamination present in the fluid, environmental conditions, and type of use can significantly dictate the replacement schedule.

Yes, Stauff Filters are designed to perform effectively in challenging conditions, offering reliable filtration even in extreme temperatures and pressures. These filters undergo rigorous testing to ensure their reliability in environments commonly faced in sectors like mining, marine, and aerospace.

By maintaining clean fluid systems, Stauff Filters reduce resistance and energy consumption, potentially enhancing overall energy efficiency. This is crucial in hydraulic systems where efficiency translates to lower operational costs and a reduced ecological footprint.

The lifespan of a Stauff Filter varies based on usage and conditions but is generally designed to last longer than many competing products. With regular maintenance and based on proper application, users can expect reliable service over prolonged periods.

Selecting the appropriate Stauff Filter involves assessing several factors, including the fluid type, flow rate, and contamination levels. Consulting with a Stauff representative can ensure that the right specifications and configurations are met for optimal performance.

In the demanding world of industrial applications, having a filtration system you can rely on is non-negotiable. Stauff Filters, with their pioneering design and proven efficiency, represent a powerful choice for businesses committed to maintaining optimal performance and sustainability standards. Embracing these filters means not only investing in the longevity of your machinery but also upholding the values of productivity and environmental responsibility. As industries continuously evolve and face new challenges, the role of efficient and reliable filtration systems becomes increasingly paramount. Stauff Filters exemplify a commitment to excellence, ensuring that every component of machinery operates at its peak potential, thereby driving innovations and advancements in industrial applications.

As businesses continue to embrace technology and automation, the demand for high-quality filtration systems will only escalate. The transition to Industry 4.0 will see even more integrations where data analytics and real-time monitoring align with filtration performance, making Stauff Filters not just a component, but a critical element in a larger ecosystem of industrial efficiency. Investing in Stauff Filters today is an investment in future readiness, ensuring that your operations are sustainable, efficient, and prepared to meet the challenges of tomorrow.

Ultimately, the use of Stauff Filters not only enhances the operational reliability of machinery but also fosters a culture of maintenance best practices among teams. Employees become more aware of the importance of cleanliness within systems and engage in proactive maintenance, contributing to better team morale and a collective mission of excellence. This holistic approach can be the differentiator that leads companies to outperform their competitors in a rapidly evolving marketplace.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!