Stauff Filters are integral components in industrial fluid power systems, ensuring the cleanliness and safety of hydraulic and lubrication fluid flows. Renowned for their precision and reliability, these filters are essential in preventing component wear and maintaining operational efficiency. By exploring the nuances of Stauff Filters, this guide provides insights into their functionality, application, and benefits.

In the realm of fluid power systems, cleanliness is crucial. The Stauff Filter emerges as a pivotal solution to uphold this cleanliness in diverse industrial environments. These filters are specifically designed to protect hydraulic systems, ensuring that contaminants do not compromise system integrity and performance. By intercepting and trapping particles, Stauff Filters play a critical role in prolonging the lifespan and efficiency of hydraulic components. The functionality of these filters is not just related to maintenance but extends to operational effectiveness and the overall reliability of the hydraulic systems in which they are integrated. This introduction aims to unravel the significance and benefits of Stauff Filters in hydraulic applications.

The primary purpose of a hydraulic filtration system is to remove contaminants from the hydraulic fluid. Contaminants such as metal particles, debris, and dirt can lead to increased wear and tear of mechanical components. Effective filtration minimizes the risk of damage, reducing maintenance costs while enhancing the reliability and performance of hydraulic systems. Within the hydraulic circuit, the fluid must maintain a certain degree of cleanliness; failure to do so can result in catastrophic failures, compromising not just efficiency but also safety. Without appropriate filtration, even a small amount of contaminants can circulate and lead to significant system disturbances, affecting not only the hydraulic components but also the entire machinery's function.

Moreover, the degradation of hydraulic fluids due to contaminants can result in the formation of sludge, varnish, and other detrimental byproducts that further impair system performance. The implementation of a robust lithium filtration solution such as the Stauff Filter directly mitigates these risks by ensuring that hydraulic fluid remains clean and free from harmful particulates. This ultimately contributes to reduced energy consumption, prolonged service intervals, and an overall increase in operational efficiency across systems that rely heavily on hydraulic power.

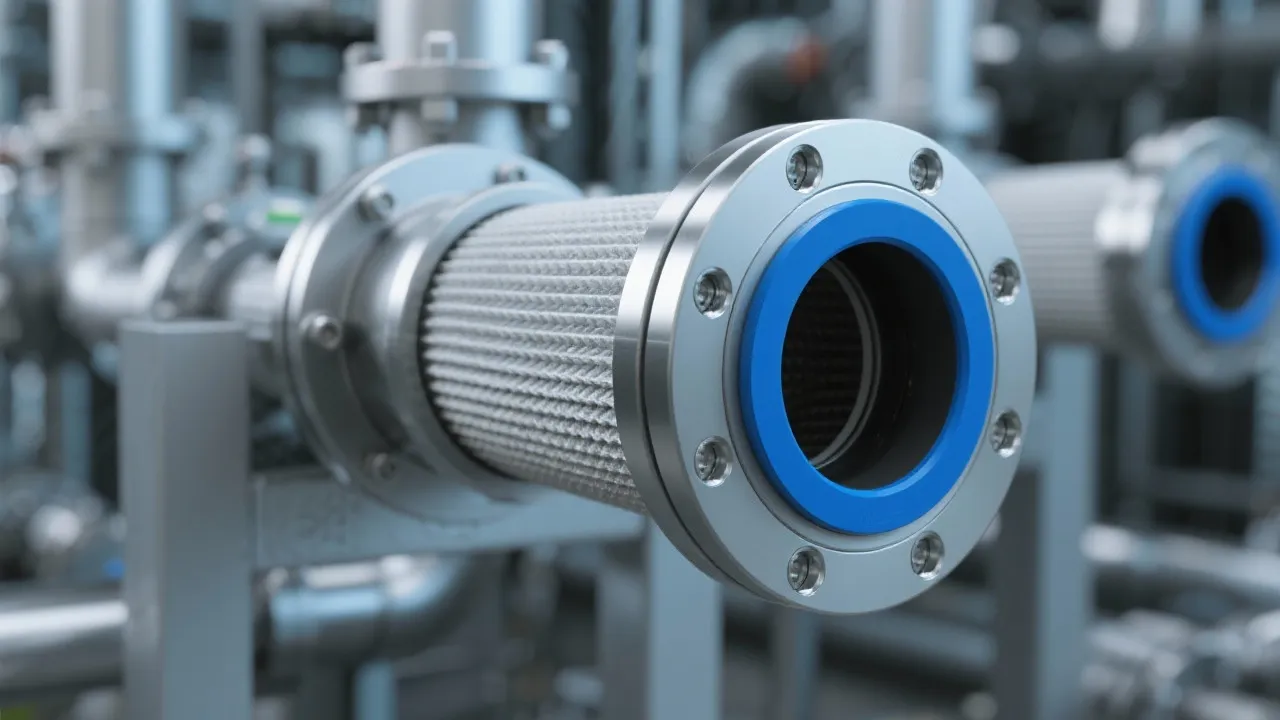

Stauff Filters are renowned for their robustness and precision engineering. Typically, these filters are available in various configurations, including spin-on filters, in-line filters, and tank filters, each designed for specific applications and flow requirements. Spin-on filters are easy to replace and maintain, making them ideal for applications where quick servicing is essential. In contrast, in-line filters are designed to be integrated directly into the hydraulic line, providing continuous filtration during operation. Tank filters are often used in oil reservoirs to prevent contamination from entering the circulation of the hydraulic system.

With options for different materials, filtration ratings, and pressure levels, Stauff Filters cater to a broad spectrum of industrial needs. The materials used in the construction of Stauff Filters range from synthetic fibers to metal mesh, allowing users to select the most suitable filter media based on their specific requirements. Hearing that certain industrial environments can expose filters to extreme conditions, Stauff Filters are often engineered to withstand considerable pressure variations, temperature extremes, and corrosive environments. This aspect of their design ensures that users can rely on their performance regardless of prevailing conditions.

Furthermore, the filtration ratings—measured in microns—reflect the size of particles that each filter can effectively capture. Stauff Filters offer options for high-efficiency ratings, targeting even the smallest contaminants, which is critical in sensitive applications such as aerospace or medical machinery where any particle could lead to equipment malfunction. The ability to provide tailored solutions based on client requirements is a hallmark of Stauff's filtration solutions, allowing them to serve a diverse range of industrial sectors effectively.

The utility of Stauff Filters extends across various industries. From manufacturing plants ensuring machinery efficiency to the aerospace industry demanding precision and safety, the application versatility of these filters is immense. In core sectors such as construction, agriculture, and automotive engineering, Stauff Filters are indispensable in maintaining hydraulic and lubrication systems.

In the automotive sector, for instance, hydraulic systems are commonly employed in brake systems and power steering. The reliability of such systems is paramount, as failure can lead to severe safety risks. Here, Stauff Filters serve a vital role by ensuring that the hydraulic fluids remain contaminant-free, thereby enhancing the reliability and longevity of these systems. Moreover, in manufacturing settings, hydraulic machinery is used for various processes including molding, cutting, and material handling. Maintaining the cleanliness of hydraulic fluid directly impacts the efficiency and output quality, reinforcing the necessity of implementing high-quality filtration systems.

Additionally, the agricultural industry utilizes hydraulic systems in tractors and other equipment extensively. Filters help ensure smooth operation and minimize disruptions during critical planting and harvesting seasons. Similarly, in construction equipment, hydraulic power is essential for excavators, bulldozers, and cranes. Stauff Filters help operators avoid costly downtime by preventing damage to hydraulic components, thereby enhancing both safety and productivity on job sites.

Selecting the appropriate filter involves several considerations. The choice hinges on factors such as the fluid type, system pressure, and contamination levels. For instance, if the fluid involved is biodegradable or may contain particulate matter from natural sources, choosing a filter rated for that specific contamination will be essential for achieving optimal results.

Furthermore, operational temperature and environmental conditions also play a pivotal role in determining the right filter. High-temperature environments may necessitate filters with specific seals and materials that can withstand thermal expansion and contraction without degrading. In dusty or particulately rich environments, a filter with a finer micron rating may be necessary to prevent damage from sand and debris.

Consulting with a filtration expert is often advisable to ensure optimal selection. Stauff offers technical consultation services to assist customers in evaluating their requirements, which can be particularly beneficial in complex applications where the wrong filter could compromise system performance. Consideration of factors such as the expected flow rate, pressure drop across the filter, and service intervals are critical to making an informed decision. Proper assessment and selection of hydraulic filters can lead to substantial cost savings in the long run.

Maintenance of Stauff Filters is paramount to their effective operation. Regular inspection and timely replacement of filter elements ensure longevity and effectiveness. Adopting a proactive maintenance schedule can prevent unexpected downtime and costly repairs. Keeping a log of maintenance activities can aid in predicting future needs and managing budgets efficiently.

Key practices for maintaining Stauff Filters involve conducting regular visual inspections for signs of damage or wear, monitoring fluid cleanliness through periodic sampling, and adhering to manufacturer-recommended maintenance schedules. By keeping an eye on pressure differential readings, operators can gain insights into the filter's condition, indicating when a replacement might be necessary. Ignoring these indicators may result in reduced flow rates, potential bypassing (where contaminated fluid passes through unfiltered), and ultimately severe damage to the hydraulic components they are meant to protect.

Moreover, utilizing advanced technologies for monitoring filter performance can enhance maintenance efficacy. Some Stauff Filters come equipped with integrated sensors that offer real-time data on filter condition and pressure, allowing for timely interventions. By integrating such smart technology, industries can enhance their predictive maintenance strategies and avoid breakdowns that may lead to extensive repair costs. Training personnel on proper maintenance and replacement protocols not only safeguards the investments made in filtration technology but also helps foster a maintenance-first culture within industrial operations.

In conclusion, the Stauff Filter stands as a testament to engineering excellence in hydraulic filtration. Its strategic role in maintaining operational efficiency and equipment longevity cannot be overstated. Understanding the specifications and application scenarios further underscores the importance of these filters in advanced industrial domains. By investing in quality filtration solutions like the Stauff Filter, industries capitalize on both productivity and protection.

Furthermore, as industrial technologies evolve, the demand for more efficient and reliable filtration methods will likely continue to grow. The innovation surrounding filtration technology—such as improvements in materials, design flexibility, and monitoring capabilities—will further enhance the effectiveness of filters like those from Stauff. This evolution ensures that industries can meet future challenges in operational efficiency and reliability.

As such, businesses that prioritize the maintenance of hydraulic systems through quality filtration solutions will not only benefit from enhanced performance and equipment servicing but also contribute to environmental sustainability by ensuring that fluid waste is minimized and managed more effectively. This multifaceted approach towards hydraulic filtration, particularly with the Stauff Filter, reflects an advancing industry committed to innovation and responsibility.

| Criteria | Description |

|---|---|

| Type | Spin-on, In-line, Tank |

| Material | Various robust materials suitable for industrial use |

| Pressure Levels | Varied configurations to suit multiple pressure requirements |

| Applications | Manufacturing, Aerospace, Automotive, Construction, Agriculture |

| Filtration Ratings | Wide range of micron ratings for various contamination levels |

| Technology Integration | Options available with real-time monitoring and diagnostics |

| Customization | Tailored solutions based on specific operational needs |

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!