This guide delves into the intricate world of proportional valves, essential components in fluid control systems that enhance performance through precise pressure and flow regulation. Widely used across various industries, proportional valves offer superior control compared to traditional valve systems by adjusting in real-time to dynamic process requirements and improving system efficiency and reliability.

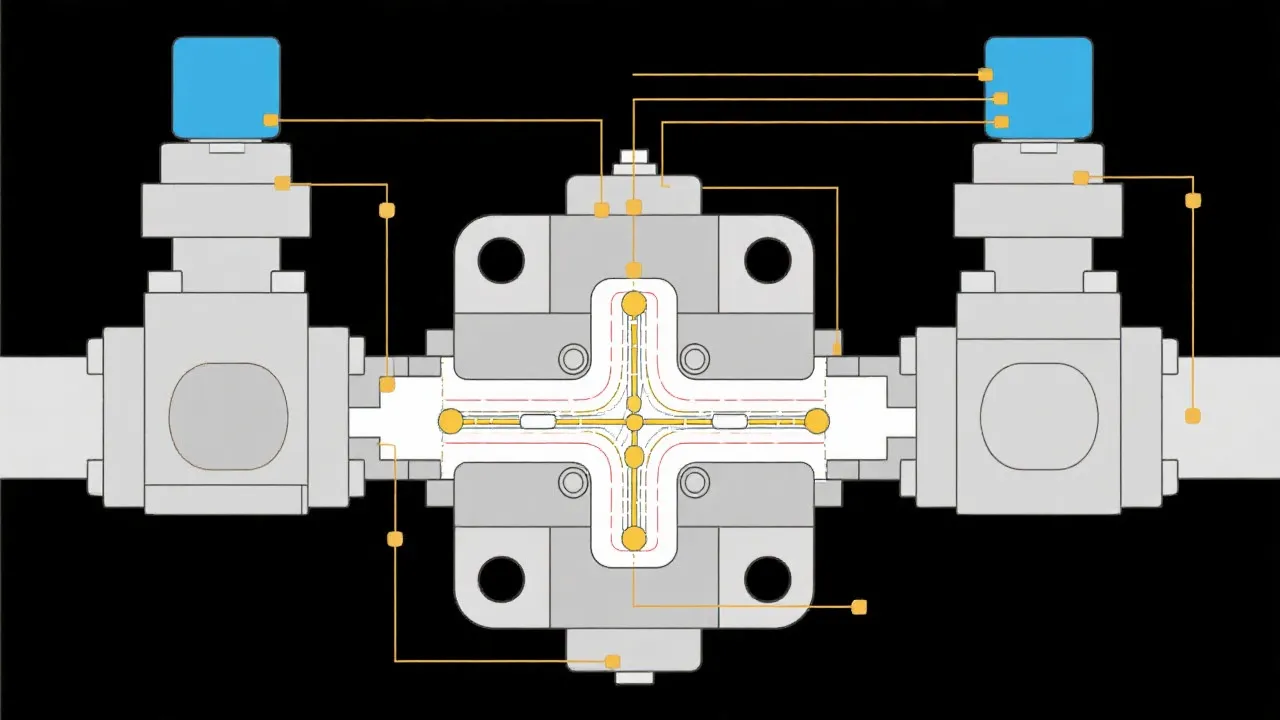

Proportional valves are pivotal in modern fluid control systems, offering enhanced precision in the regulation of pressure, flow, or both. Unlike traditional on/off valves, which operate in a binary manner, proportional valves allow for variable control based on input signals, making them crucial in applications that demand nuanced adjustments and sophisticated control characteristics. Proportional valves are not merely components; rather, they are innovations that enhance system capability, facilitate efficiency, and enable seamless integration into various industrial processes. From aerospace applications where precision is non-negotiable, to high-demand manufacturing processes that require adaptability, these valves harness state-of-the-art technology to optimize performance, ensuring systems run smoothly, efficiently, and effectively.

The core advantage of a proportional valve lies in its ability to deliver varying output proportional to an input signal, often from an electronic controller or other sensors. This unique capability allows for better process control across different conditions, leading to consistent performance in environments where variables such as temperature, pressure, or load may change continuously. Proportional valves contribute significantly to energy-saving initiatives by maintaining optimal flow and pressure in hydraulic and pneumatic systems; this reduces wastage and operational costs, enhancing economic viability for businesses.

One prominent aspect of proportional valves is their implementation of advanced response mechanisms, which enable them to react quickly to changes in demand. This agility is particularly advantageous in dynamic environments where fluid control directly impacts productivity. Moreover, the feedback mechanisms inherent in many proportional control systems ensure a constant adjustment of flow and pressure, providing reliability that traditional valves cannot match. This reliability translates into less downtime and more consistent operational metrics, which are paramount in high-stakes industries such as manufacturing, healthcare, and defense.

Proportional valve technology has seen numerous innovations over recent years, driven by the need for greater efficiency, precision, and control. Advances in materials have led to the development of lightweight, durable components that withstand harsh environments, while innovative designs focus on minimizing leakage and other forms of waste. Electronic controls have drastically improved, allowing for real-time communication with other components in a system. This is often achieved through the use of proportional-integral-derivative (PID) controllers, which analyze input signals and adjust valve positions to maintain desired outputs dynamically.

Furthermore, the integration of embedded sensors within proportional valves has revolutionized their functionality. Sensors can monitor various operational conditions such as temperature, pressure, and flow rate directly from the valve, providing critical data for diagnostics and system optimization. The advent of digital interfaces facilitates remote monitoring and adjustments, giving operators greater flexibility to respond to operational challenges swiftly. With mobile technology and IoT integration, operators can even access data remotely, making it possible to diagnose and make adjustments from virtually anywhere.

Proportional valves are employed in a wide array of industries, each benefiting from their unique capabilities. In the automotive sector, for instance, they're integral to braking systems and engine management, facilitating responsive control of hydraulic and pneumatic functions that are crucial for safety and performance. Additionally, in systems designed for automated production lines, these valves manage the movement and manipulation of materials with precision, significantly enhancing throughput and reducing cycle times.

In construction, proportional valves serve in heavy machinery for driving axial pistons and controlling hydraulic pumps, which are paramount in equipment such as excavators and bulldozers. These applications require robust control over varying loads and power sources, making proportional valves an essential component for optimal performance in tough conditions.

Moreover, the medical field utilizes proportional valves in devices such as ventilators and infusion pumps, where precise flow regulation is not just desirable but essential for patient safety and comfort. The healthcare industry increasingly relies on such technology as it moves towards more automated and sophisticated systems, requiring enhanced monitoring and responsiveness. Each of these examples exemplifies the versatility and significance of proportional valves in complex operational contexts.

| Feature | Proportional Valve | Traditional Valve |

|---|---|---|

| Control Precision | High precision with variable control | Limited to on/off control |

| Energy Efficiency | High due to reduced wastage | Lower due to binary operation |

| Technical Complexity | Requires sophisticated electronic controls | Simpler mechanical build |

| Response Time | Fast and dynamic adjustments | Slow, with fixed positions |

| Maintenance Requirements | Often requires calibration and software updates | Minimal, with simpler mechanical parts |

| Integration Capabilities | Can be integrated with IoT and advanced control systems | Limited integration options |

When incorporating proportional valves into a system, engineers must consider multiple factors encompassing system requirements, environmental conditions, and performance objectives. The selection of appropriate valve type and configuration is paramount to ensuring tailored performance that aligns with operational goals. This demands a thorough understanding of the specific applications and the demands they impose on fluid control systems.

Proper installation and maintenance remain critical components of successful proportional valve deployment. Engineers should conduct comprehensive training for technicians and operators to ensure they understand the advanced functionalities and requirements of these valves. Regular calibration and inspection can prevent failures and extend the service life of the valves, ensuring that systems operate at peak efficiency. Preventative maintenance programs should include not just physical inspections but also technical diagnostics to detect any deviations from expected performance metrics.

In addition, integrating proportional valves with existing systems often presents unique challenges. Retrofitting current machinery with proportional control can require significant modifications, not just to the valves themselves but also to the control circuitry and overall system architecture. Understanding legacy systems and their compatibility with new technologies is essential. Working closely with manufacturers and system designers can facilitate smoother transitions and help avoid costly missteps during implementation.

In conclusion, proportional valves represent a leap forward in fluid control technology, offering unparalleled precision and adaptability. Their unique ability to adjust flow and pressure in real-time enables industries to achieve higher efficiency and control, which is critical as businesses strive for competitiveness in increasingly complex environments. As industries continue to demand efficiency, precision, and reliability, proportional valves will remain integral to optimizing processes and driving technological innovations. Their role not only enhances immediate operational capabilities but also serves as a foundation for future advancements in automation and smart manufacturing, paving the way for intelligent systems that can interpret and react to data autonomously.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!