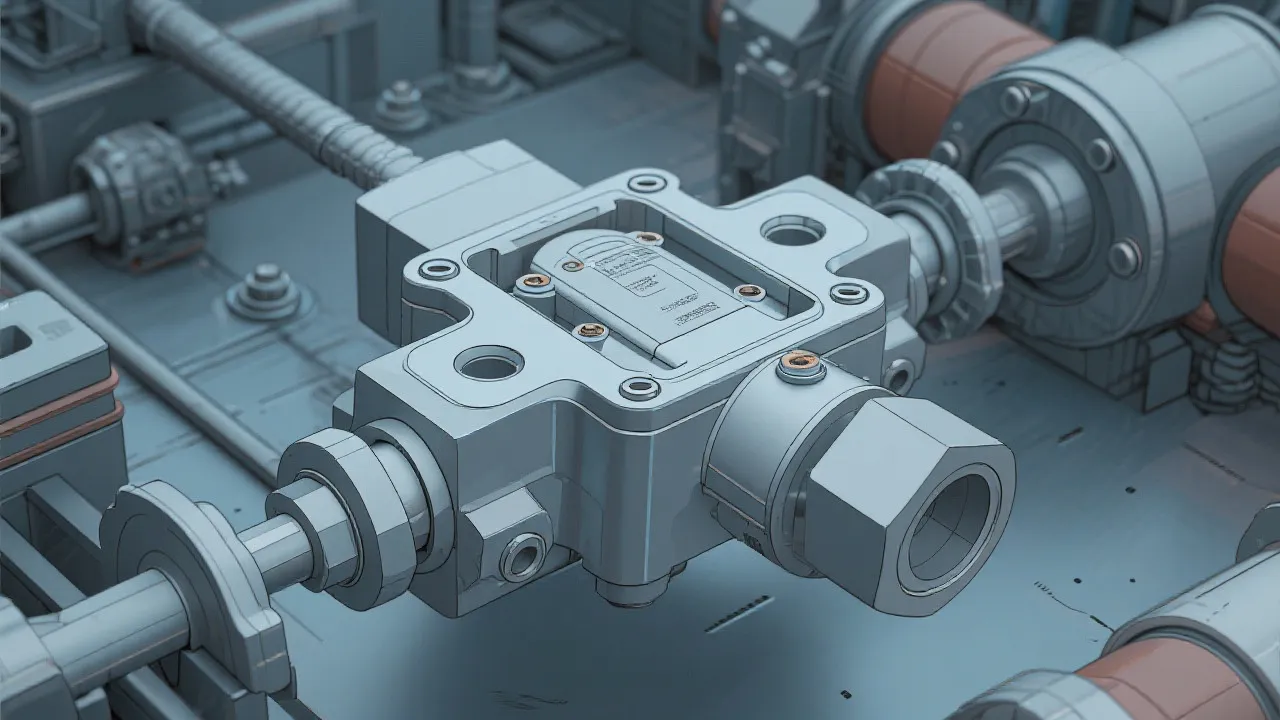

Proportional valves are essential components in fluid control systems, providing precise regulation of flow and pressure. Used extensively in various industries, these valves optimize system efficiency by adjusting flow output according to electrical signals, ensuring both reliability and advanced control. This article delves into the functionality, types, and applications of proportional valves, offering an in-depth exploration guided by industry expertise.

Proportional valves are crucial components within modern fluid control systems. Their ability to precisely regulate the flow and pressure of fluids based on electronic feedback provides an unparalleled level of control across various industrial applications. From manufacturing and automation to aerospace and medical fields, the proportional valve ensures optimal efficiency and adaptability.

The evolution of fluid control systems has marked significant advancements in technology and engineering practices, making proportional valves a necessary addition to systems where precise control is paramount. The growing complexity of machinery and processes in industries such as automotive manufacturing and robotics has escalated the demand for reliable components capable of providing fine-tuning in real-time. As industries continue to innovate, the role of proportional valves becomes increasingly important in enhancing the performance and capabilities of these systems.

At the heart of a proportional valve is its ability to adjust flow and pressure in real-time. Unlike traditional valves that feature binary operations (fully open or closed), proportional valves can finely modulate their position based on the voltage or current signal applied. This fine-tuning allows for smooth operation, reduced energy consumption, and enhanced system responsiveness. Modern proportional valves can achieve nearly infinite orientations between fully closed and fully opened, thus providing a precise control aspect that is highly beneficial in many applications.

The core functionality is defined by its electromechanical innards, which include a solenoid, a spool, and springs. Upon receiving electrical input, the solenoid generates a magnetic field, moving the spool and consequently adjusting the flow area within the valve. This intricate relay of mechanical and electrical signals ensures the accurate alignment of pneumatic or hydraulic systems to their specific requirements. The interaction between these components allows the valve to respond swiftly to changes in operational demands, providing stability to fluid flow under varying conditions.

The integration of sensors within the system can further enhance the operation of proportional valves, enabling feedback mechanisms that optimize performance based on real-time data analysis. This creates a more adaptive system that not only responds to external demands but can also predict needed adjustments based on prior patterns of use. Such innovations in valve technology demonstrate that future developments may lean towards incorporating smart technologies and Internet of Things (IoT) functions in proportional valve systems.

In industrial applications, proportional valves are integral to the smooth operation of complex systems across various sectors:

The integration of proportional valves within a system brings several advantages that span multiple aspects of performance and efficiency:

Unlike traditional valves that operate only in fully open or closed states, proportional valves can variably adjust their position, allowing for detailed control over flow and pressure. This means that proportional valves don't just turn on or off; rather, they provide a degree of control akin to a dimmer switch for lights, allowing for better regulation of flow across a range of parameters.

Yes, proportional valves can handle various fluids, from gases to hydraulic oils, making them suitable for diverse applications. That said, the choice of materials and specific design characteristics may vary depending on the fluid's properties, such as viscosity, temperature, and chemical reactivity. Evaluating the compatibility of materials used in the construction of the valve with the intended fluid is a crucial step in application design.

Pilot-operated valves use an additional pilot stage to manage larger flows and pressures, whereas direct-operated valves are suited for lower ranges by directly controlling the spool. The pilot stage allows for more efficient handling of significant pressure differences, making pilot-operated valves ideal for high-capacity requirements or larger machinery, where the need for power surpasses the capability of directly operated designs.

Regular inspection and cleaning are vital, given the precision components involved. Ensuring seals and spools are in good condition will enhance longevity and function. Additionally, monitoring the electrical components for wear or malfunctions is essential to maintaining the responsiveness of proportional valves. Employing a scheduled maintenance regime can significantly enhance reliability, minimizing downtime in industrial applications.

Yes, in most cases, proportional valves can be incorporated into existing hydraulic or pneumatic systems without major modifications. However, it is crucial to ensure compatibility with the current control systems, as well as proper sizing to maintain operational efficiency. Sometimes, implementing proportional valves may require updates to electronic controls or integration with advanced sensor systems to fully utilize their capabilities, thereby requiring a careful assessment of both current technological and infrastructural adequacies.

Proportional valves demonstrate remarkable versatility and precision in system control, making them indispensable in modern industry. Their ability to enhance system reliability while ensuring optimal performance secures their place as a critical component of fluid control systems worldwide. As industries evolve with emerging technologies and further complexity in operations, proportional valves are set to evolve alongside them, offering increasingly sophisticated solutions to meet contemporary demands. Whether in manufacturing plants, high-tech aerospace environments, or critical care medical situations, the effectiveness of proportional valves will continue to shape the landscape of fluid control for years to come.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!