This article provides an in-depth exploration of proportional valve technology, key to modern fluid control systems. Proportional valves are extensively used in hydraulic and pneumatic systems to precisely regulate pressure and flow. By understanding their operation and numerous applications, one can appreciate their role in advancing industrial automation and efficiency.

Proportional valves are essential components in industrial fluid control systems. They enable precise regulation of flow and pressure within hydraulic and pneumatic circuits, which are critical for automation and process control. Unlike traditional on/off valves, proportional valves allow for variable control, which improves efficiency and accuracy in various applications, from industrial manufacturing to sophisticated robotics. The significance of proportional valves extends beyond their functionality; they represent a key advancement in engineering, providing solutions that adapt to the dynamic nature of modern industrial processes.

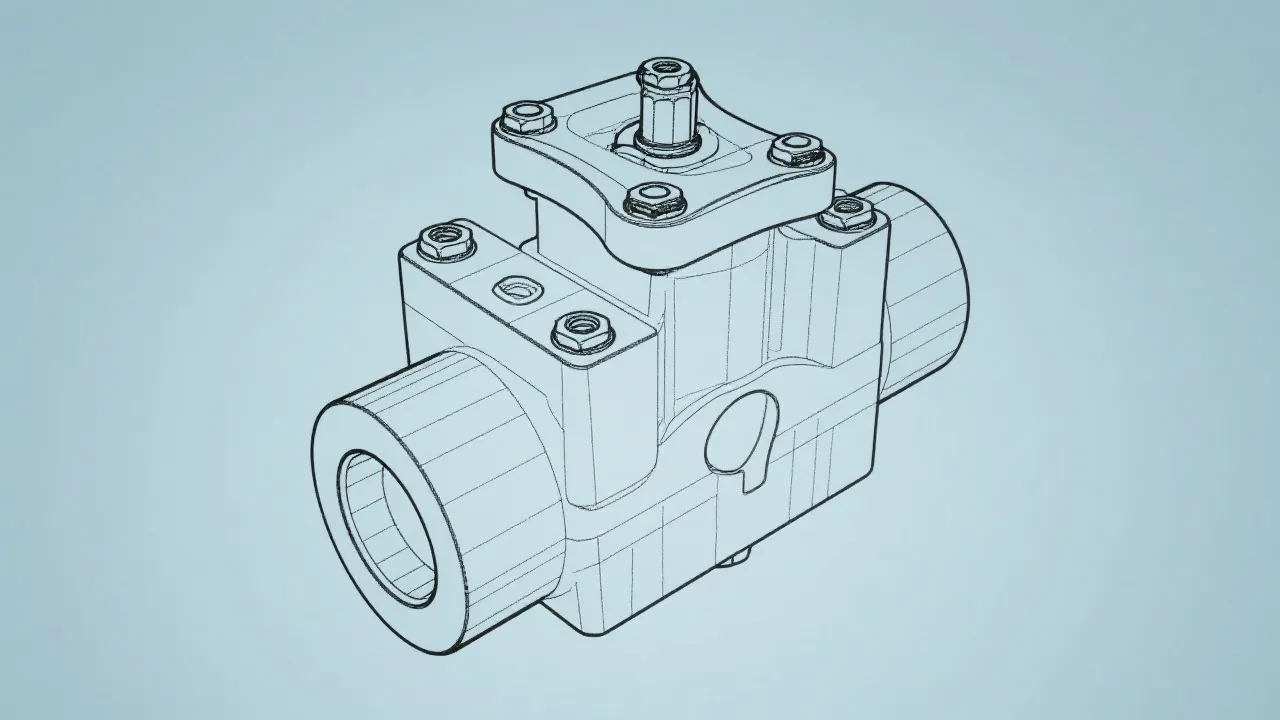

A proportional valve operates by varying its opening in response to an input signal, usually electrical. This variable opening allows for a corresponding modulation in flow rate and pressure. The precise control mechanism often involves solenoids or electric motors, translating electrical inputs into mechanical motion. This enables proportional valves to react to changes in system demands dynamically, maintaining optimal system performance. Additionally, modern proportional valves may incorporate advanced electronics and feedback systems. This design allows for more precise control and faster response times, making them ideal for applications that require real-time adjustments to operating conditions.

To delve deeper into how proportional valves work, it’s essential to understand the primary mechanisms involved. Most proportional valves utilize a feedback loop that continuously monitors the output parameters—typically pressure or flow rate. A sensor measures the output and relays this information back to a controller, which adjusts the valve position in real-time to achieve the desired setpoint. This sophisticated interaction between components ensures that deviations from preset conditions are corrected swiftly, leading to a high degree of system stability and performance consistency.

Proportional valves are widely utilized in sectors like automotive manufacturing, aerospace, and industrial machinery. In automated systems, they enable fine-tuned control of actuator speed and force. They are also crucial in the medical field, particularly in devices that require precise gas or fluid delivery. For instance, in anesthesia machines, proportional valves help manage the flow of gases to patients, ensuring safety and effectiveness during surgical procedures. In the landscape of renewable energy, they ensure that systems, such as wind turbines, operate efficiently by modulating power generation components under varying wind speeds. A detailed overview of their applications highlights their versatility and capability to enhance operational efficiency and safety across numerous fields.

In the fast-evolving field of robotics, proportional valves play a vital role in controlling the movements and operations of robotic arms and other actuator mechanisms. For example, in industrial robotic arms used for assembly or packaging, proportional valves provide precise control of pneumatic systems that grip, rotate, and move components. By allowing modulation in speed and force, these valves enable robots to perform delicate operations that require high precision, such as picking and placing fragile items or intricate assembly tasks. The ability to adjust the force applied by the robotic gripper based on the item’s sensitivity is a direct application of proportional valve technology, showcasing its importance in advancing automation capabilities.

Several types of proportional valves exist to suit different applications. These include:

Here is a comparative analysis of different types of proportional valves:

| Valve Type | Primary Function | Typical Applications |

|---|---|---|

| Directional Proportional Valve | Controls fluid direction and flow rate | Industrial Automation, Robotics |

| Pressure Proportional Valve | Maintains consistent output pressure | Aerospace, Hydraulic Systems |

| Flow Control Proportional Valve | Regulates flow to manage pressure | Medical Devices, Wind Energy |

Proportional valves offer several advantages, including superior control over traditional valves, which leads to energy savings, reduced wear and tear on machinery, and improved overall system efficiency. Additionally, proportional valves contribute to enhanced safety through precise control of potentially hazardous materials in industrial settings. Another significant benefit is their adaptability. Proportional valves can be configured for a wide range of fluid types and applications, making them incredibly versatile. Their ability to handle varying flow rates and pressures not only broadens their applicability but also simplifies control architecture within complex industrial systems.

While proportional valves present numerous benefits, there are challenges and considerations that need to be addressed for effective implementation. One such challenge is the requirement for sophisticated control systems. The feedback loop and overall technology used in proportional valves demand more complex electronic control, which might increase initial investment costs and necessitate skilled personnel for operation and maintenance.

Another consideration is the environmental conditions under which these valves operate. For example, exposure to extreme temperatures, dirt, or corrosive substances can affect a valve's longevity and reliability. Therefore, selecting the appropriate materials and protection mechanisms for specific environments is crucial to ensure the longevity and efficiency of proportional valves. Regular maintenance is also essential to prevent wear and ensure that the valves maintain their functionality and performance over time.

As technology advances, the role of proportional valves will become increasingly vital in developing innovative and sustainable solutions for various industrial challenges. One key area of development is the integration of Internet of Things (IoT) capabilities. By incorporating IoT technologies, proportional valves can provide real-time data and diagnostics, allowing for predictive maintenance and improved operational efficiency.

Moreover, advancements in materials science are anticipated to improve the durability and performance of proportional valves. New materials may be developed to withstand harsher environments or to improve energy efficiency. Additionally, software algorithms could enhance the interaction between these valves and their control systems, leading to smoother operational dynamics and more intelligent industrial automation.

In summary, proportional valves are pivotal in modernizing fluid control systems across several industries. Their ability to precisely manage flow and pressure not only enhances operational efficiency but also ensures safety and reliability. As technology advances, the role of proportional valves will become increasingly vital in developing innovative and sustainable solutions for various industrial challenges. Their expanding applications and improvements in technology highlight their importance, ensuring that they will remain at the forefront of fluid control solutions for years to come.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!