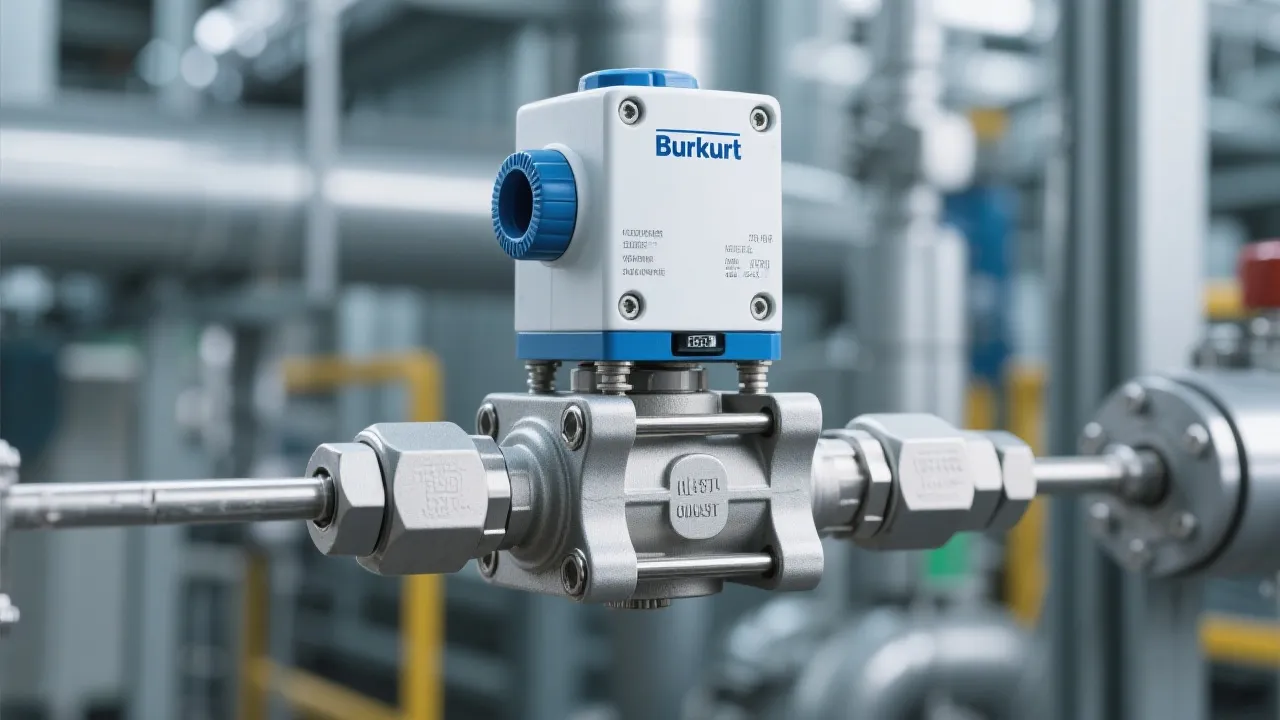

Delve into the world of Burkert Proportional Valves, which are indispensable components for controlling fluid flow with precision in industrial settings. Known for their reliability and efficiency, these valves are integral in various sectors, from chemical processing to food and beverage, where maintaining optimal fluid control is essential. This guide provides a comprehensive analysis of its applications, benefits, and operational insights.

Burkert Proportional Valves represent a crucial component in fluid control technology, delivering essential precision and reliability across a multitude of industrial applications. These valves are engineering marvels, designed to dynamically adjust the rate of flow to maintain predetermined conditions in real-time. Their importance spans industries including chemical processing, food and beverage, pharmaceuticals, HVAC systems, and further extends into emerging technological fields such as automation and robotics. The flexibility and adaptability of these valves equip industries with the tools necessary to enhance productivity and ensure operational efficiency.

The fundamental purpose of a Burkert Proportional Valve is to regulate the flow of fluids—whether gases, liquids, or steam—thus preserving a defined flow rate. Unlike traditional valves that operate on a binary principle of fully open or fully closed, proportional valves provide continuous modulation of flow between these states. This ability enables the precise control necessary for applications that demand exact fluid dynamics.

Advanced technologies such as electric, pneumatic, or even stepper motor actuators empower these valves to respond swiftly to control signals, thereby adjusting flow rates as required. Such rapid response capabilities are a game changer, especially in processes where timing and precision can significantly impact quality and safety. This level of control not only guarantees operational efficiency but also contributes to energy savings, a growing consideration in an era where industries are increasingly committed to sustainability practices.

Burkert Proportional Valves play a vital role in various industrial landscapes, demonstrating their versatility and adaptability:

The distinct advantages of Burkert Proportional Valves make them a preferred choice for industries aiming for precision and reliability.

To unlock the full potential of Burkert Proportional Valves, it is imperative to adhere to specific operational insights and top practices:

The following comparison highlights specific characteristics of different models of Burkert Proportional Valves. This table can serve as a quick reference guide for professionals looking to select the appropriate valve for their applications:

| Model | Actuation Method | Flow Range | Applications |

|---|---|---|---|

| Type 8712 | Electric Actuator | 0.1 to 3500 l/min | General Process Control |

| Type 2836 | Pneumatic Actuator | 0.05 to 300 l/min | Precise Gas Control |

| Type 6024 | Universal Actuator | Customized | Fluid and Gas Control |

| Type 8131 | Electric Actuator | 0.5 to 2500 l/min | High-Performance Applications |

| Type 2100 | Pneumatic Actuator | 0.1 to 500 l/min | Water Treatment |

| Type 8231 | Electric Actuator | 0.02 to 2000 l/min | Acoustic Applications |

Q: What makes Burkert Proportional Valves unique compared to other brands?

A: Burkert Proportional Valves offer unmatched precision and reliability, supported by innovative technology that enhances operational efficiency across a broad range of applications. They are specifically engineered to meet high standards in challenging conditions.

Q: How do these valves contribute to energy savings?

A: These valves facilitate precise control of fluid dynamics, which optimizes resource consumption. By ensuring that only the necessary amounts of fluids are utilized, they significantly reduce energy expenditure, allowing for greener operational practices.

Q: Are Burkert Proportional Valves suitable for emerging fields?

A: Absolutely. Their high precision and adaptability make them ideal for advanced manufacturing, automation systems, and research in emerging fields where maintaining exact conditions is critical.

Q: What are the maintenance requirements for these valves?

A: Regular checks, routine calibration, and skilled personnel are fundamental to maintaining their operational integrity. Additionally, integrating monitoring systems can help track the health of the valves, driving the need for timely maintenance interventions.

Q: Can these valves handle corrosive fluids?

A: Yes, many models are specifically designed to handle corrosive fluids as long as they are made from appropriate materials. It's essential to select the correct materials based on the media being processed to ensure longevity and performance.

Q: What industries benefit the most from Burkert Proportional Valves?

A: Industries such as chemicals, food and beverage, pharmaceuticals, water treatment, and HVAC systems benefit significantly from the precision and control offered by Burkert Proportional Valves, alongside others like aerospace, automotive, and energy sectors.

With continuous advancements in technology, Burkert Proportional Valves continue to set industry standards. They play a pivotal role in facilitating efficient, sustainable, and high-quality industrial processes worldwide. As industries strive for greater efficiency and sustainability, the incorporation of these advanced valves is becoming increasingly indispensable, enabling the optimization of fluid handling and process management across various sectors. The ongoing innovation within the Burkert portfolio ensures that they remain at the forefront of fluid control technology, tailoring solutions to meet the rapid developments and unique challenges presented by modern industrial applications.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!