This article delves into the intricacies of proportional valves, crucial components in fluid control systems used to adjust the flow or pressure without stopping the process. Proportional valves are vital in various industries such as automotive, aerospace, and manufacturing due to their ability to enhance precision and efficiency in automated systems. Understanding their functionality can significantly contribute to optimized industrial processes.

Proportional valves are a fundamental component in modern fluid control systems due to their ability to precisely regulate flow rates or pressure levels proportional to an input signal. This functionality is essential in ensuring optimal performance across various industries, including automotive, aerospace, and manufacturing. As automation continues to evolve, these valves play a pivotal role in enhancing system responsiveness and efficiency. The integration of technology in fluid control applications has led to a growing demand for proportional valves, reinforcing their significance in both conventional and cutting-edge industrial operations.

Proportional valves are distinguished by their ability to provide variable output based on input signals, typically in the form of an electrical current or voltage. This characteristic enables precise control of fluid dynamics, which is paramount for applications demanding high fidelity responses. Additionally, proportional valves can be controlled via digital signals, allowing for better integration into modern automated systems. The benefits of using proportional valves include improved system efficiency, reduced energy consumption, and enhanced precision in operations that necessitate meticulous control over environmental variables. Furthermore, the ability to fine-tune the performance of proportional valves leads to increased system longevity by preventing unnecessary wear and tear associated with abrupt on/off cycling.

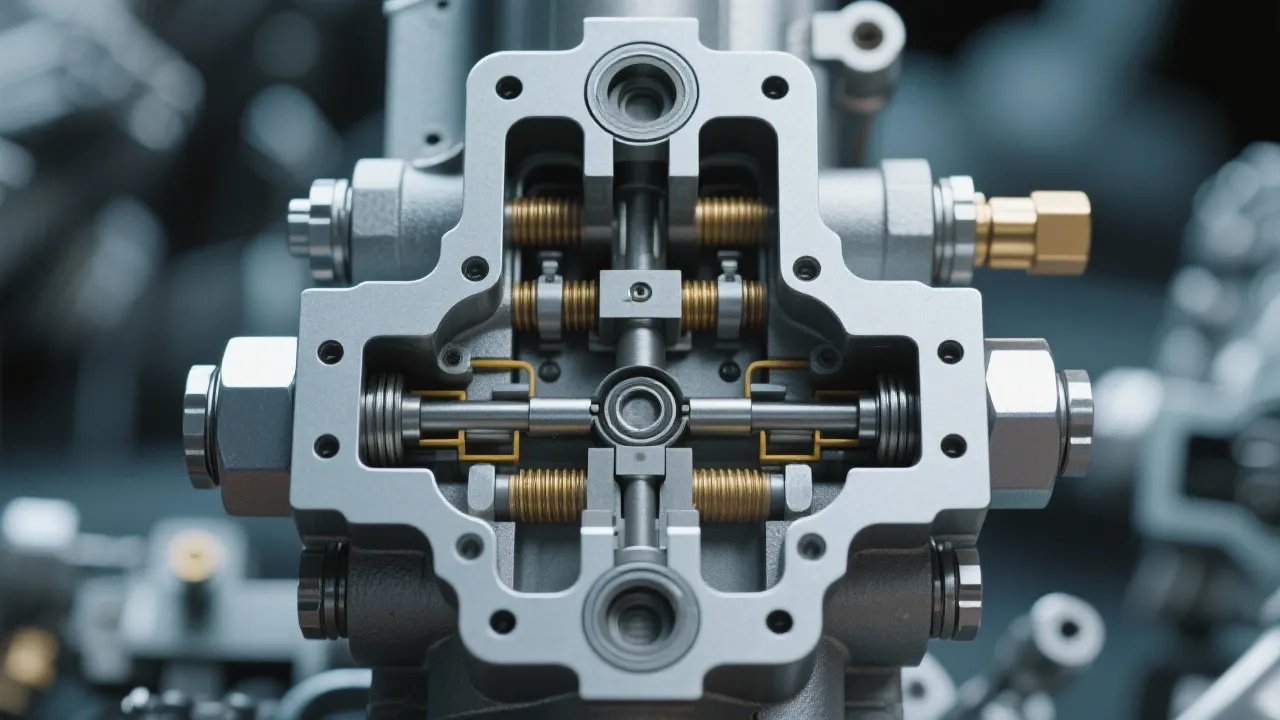

Functionally, proportional valves operate through a combination of mechanical and electronic components. The primary mechanism involves a coil and spool assembly that alters its position in response to electrical input. By modulating the position of the spool within the valve, the flow of fluid is controlled proportionally. The electronic control unit sends a voltage signal that corresponds to the desired flow or pressure, translating into spool movement. This dynamic adjustment is what grants these valves their high degree of precision in various industrial applications. Moreover, with advancements in technology, many proportional valves now integrate feedback systems that allow for real-time monitoring and adjustment of valve position, further enhancing accuracy and response time.

The versatility of proportional valves makes them indispensable across multiple sectors. In the automotive industry, they are employed in fuel injection systems to ensure accurate fuel delivery, optimizing engine efficiency and reducing emissions. Similarly, in aerospace, these valves help regulate hydraulic fluids in flight control systems, where precise actuation is critical for safety and performance. The manufacturing sector utilizes them in machinery for maintaining consistent pressure and flow, thereby optimizing production lines and enhancing overall throughput.

In addition to these applications, the process industry, including oil and gas, chemical production, and water treatment, relies on proportional valves for controlling fluid systems. For example, in chemical processing plants, these valves regulate the flow of reactants and products to ensure optimal reaction conditions and prevent hazardous situations. Furthermore, proportional valves have found applications in robotics and automation, where their ability to offer precise movement control is essential for tasks such as pick-and-place operations and assembly processes.

| Aspect | Proportional Valve | Standard Valve |

|---|---|---|

| Control | Variable, proportional response | On/Off, fixed response |

| Efficiency | High, due to precise flow management | Moderate, requires additional components for variance |

| Cost | Higher initial investment, cost-effective in the long term | Lower initial investment, higher operational costs |

| Complexity | Complex, requires precise electronic control | Simple, more straightforward valve operation |

| Response Time | Fast, suitable for dynamic applications | Slow, less responsive to variations |

Choosing the right proportional valve involves assessing several factors to ensure compatibility with the intended application. Key considerations include:

Additional considerations include valve form factor, mounting options, and environmental ratings (such as IP code for ingress protection), which are essential for ensuring reliability in specific applications. Ultimately, the accurate selection of proportional valves can lead to improved performance, reduced operational costs, and enhanced system durability over time.

Q1: What industries commonly use proportional valves?

A: Proportional valves are widely used in automotive, aerospace, manufacturing, oil and gas, water treatment, and even biotechnology sectors due to their precision and efficiency.

Q2: How do I maintain a proportional valve?

A: Regular maintenance involves inspecting the electrical connections, ensuring the valve components are clean, and monitoring the performance to identify and address any deviations promptly. Periodic calibration may also be necessary to ensure the valve operates within specification and maintains accuracy.

Q3: Can proportional valves be used for both liquids and gases?

A: Yes, many proportional valves are designed to handle both fluids and gases, but it's essential to verify the specifications to ensure compatibility with your specific application. Gas and liquid properties may require different considerations in terms of valve design and materials.

Q4: What advancements are being made in proportional valve technology?

A: Recent advancements include the integration of smart sensors for feedback control, improvements in valve materials for better durability, and the development of more compact designs that facilitate integration into space-constrained applications. Additionally, the incorporation of IoT technology allows for remote monitoring and control, enhancing system responsiveness and adaptability.

Q5: Are there specific brands or manufacturers known for high-quality proportional valves?

A: Yes, several reputable manufacturers are well-known for producing reliable proportional valves, including Parker Hannifin, Bosch Rexroth, Danfoss, and Festo. These companies typically offer a range of products to cater to various applications and provide extensive support for selection and maintenance.

Incorporating proportional valves into industrial systems offers significant advantages in terms of control, efficiency, and adaptability. Their ability to respond dynamically to changing conditions paves the way for enhanced operational insights and streamlined automation processes. As automation advances, understanding and leveraging the capabilities of these valves will be crucial for industries striving for enhanced precision and performance. By selecting the appropriate valve specifications, businesses can ensure seamless integration into existing processes, thereby achieving their operational goals more efficiently. Furthermore, with the continuous improvement in technology and materials, the future of proportional valves is promising, with the potential to drive innovation across various sectors.

In conclusion, the strategic implementation of proportional valves can lead to sustainable advancements in industrial operations. As companies increasingly focus on efficiency and precision, the significance of proportional valves will only grow, marking them as vital components for future fluid control systems. As such, investing in proper selection, maintenance, and integration practices will be essential for harnessing their full potential in challenging environments.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!