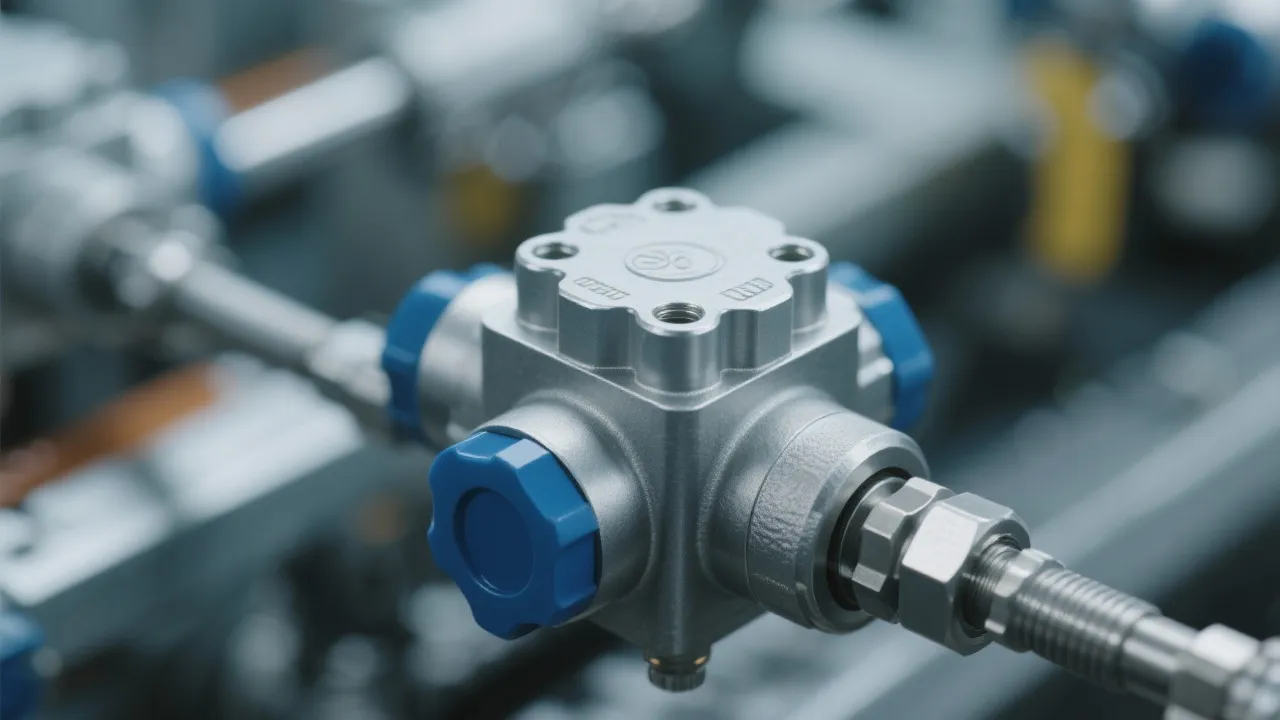

Proportional valves are essential components in industrial systems, allowing precise control over fluid flow and pressure. Their importance lies in their ability to enhance system performance, reduce energy consumption, and ensure operational safety. This article delves into the functionalities, types, and applications of proportional valves, providing a comprehensive overview for industry professionals.

Proportional valves are indispensable in modern industrial applications. They provide advanced control over fluid flow and pressure, crucial for optimizing various processes. These valves adjust the output in a linear manner relative to an input signal, which can be either electric or pneumatic. This precise control is vital for maintaining system stability, efficiency, and safety, making them a preferred choice in various sectors like manufacturing, automotive, and chemical processing.

In recent years, the demand for precision in industrial processes has grown significantly as companies strive to improve their efficiency and product quality. Consequently, the role of proportional valves has become increasingly important. With the evolution of automation technologies, these valves are integrated into complex control systems, allowing for real-time data feedback and adaptive responses to varying operational conditions. Proportional valves are not just mechanical components; they are critical parts of smart systems that enhance operational efficacy through data-driven decision-making processes.

At the core of a proportional valve's functionality is its ability to provide variable control rather than a simple on-off mechanism. This nuanced control is achieved through a modulating element, typically a spool or diaphragm within the valve, which adjusts fluid passage based on an input signal. One of the primary advantages of using proportional valves is their capacity to reduce energy consumption by ensuring that systems operate at optimal levels, responding dynamically to changes in demand.

The precise control offered by proportional valves leads to a multitude of benefits. First and foremost, they enhance operational efficiency. For example, in hydraulic systems, the ability to fine-tune fluid flow can prevent the overheating of components, thus extending their operational lifespan and reducing maintenance costs. Furthermore, proportional valves contribute to overall system safety by allowing for smoother operation in critical applications, such as those found in aerospace and automotive industries, where fluctuations in pressure and flow can lead to catastrophic failures.

Another notable benefit of proportional valves is their ability to enhance process control. In manufacturing, the quality of the final product is often influenced by how well fluid dynamics are regulated. Proportional valves allow for precise adjustments that can be communicated through integrated systems, ensuring consistent output quality. Additionally, their functionality lends itself to a wide range of applications, from simply controlling the speed of actuators to managing complex systems in large-scale production facilities.

Proportional valves come in several types, each suited for specific applications:

Proportional valves find applications across a wide range of industries:

| Type | Typical Application | Key Benefits |

|---|---|---|

| Electrically Actuated | Precision manufacturing | High accuracy and control |

| Pneumatically Actuated | Hazardous environments | Safely handle explosive conditions |

| Hydraulic | Heavy machinery | Handles high pressure efficiently |

| Magnetically Ported | Advanced automation | Fast response times |

| Servo | High-precision applications | Closed-loop control for accuracy |

They offer precise control, energy efficiency, and improved system performance. Their adaptability allows businesses to enhance productivity while reducing operational costs.

While designed largely for industrial uses, some high-end HVAC systems may incorporate them for better climate control. They can also be employed in advanced irrigation systems to optimize water usage based on environmental conditions.

Consider the application's specific requirements such as pressure, flow rate, and environmental conditions. Additionally, assess the control signal type needed and the integration capacity with existing systems.

Like many components within industrial systems, proportional valves have undergone substantial technological advancements over recent years. These enhancements have typically focused on improving control accuracy, durability, and integration capabilities with modern control systems.

One of the most significant advancements has been in the realm of digital connectivity. Many new models of proportional valves now incorporate features like advanced feedback systems that allow for real-time monitoring of valve performance. These systems can communicate with PLCs and other automation devices to share data on flow rates, pressures, and operating conditions, enabling predictive maintenance and operational adjustments based on real-time information.

Moreover, the integration of Internet of Things (IoT) technologies into proportional valve designs is transforming how they operate within larger systems. IoT-enabled valves can be monitored and controlled remotely, allowing operators to adjust settings to optimize performance from virtually anywhere in the world. This connectivity also paves the way for enhanced analytics, as data collected over time can be analyzed to identify recurring issues, enabling better decision-making regarding system designs and maintenance schedules.

Another key area of advancement is in the materials used for manufacturing these valves. New composites that are resistant to extreme temperatures and corrosive environments are becoming more common, increasing the longevity and reliability of proportional valves in various applications. These materials help to mitigate wear and tear and ensure that the valves perform consistently under a range of operational conditions.

Maintenance is vital for ensuring the longevity and effective operation of proportional valves. Regular inspection and upkeep can prevent unexpected system failures, extending the operational life of both the valves and the machinery they control.

The maintenance routine for proportional valves generally includes checking for leaks, verifying the integrity of the sealing surfaces, and ensuring the actuation mechanisms are functioning correctly. Accumulations of debris and sediment can impair the valve's functionality, so cleaning components regularly is essential. In hydraulic systems, for instance, maintaining the oil quality and filtering return lines can ease the strain on the valves and other hydraulic components.

Calibration is another important aspect of maintenance. Proportional valves must be periodically calibrated to ensure they respond correctly to control signals. This is particularly crucial in applications where precise pressure or flow rates are integral to the process. Calibration involves comparing the valve's output to known standards and making adjustments to the control parameters as necessary.

In addition to conventional maintenance practices, operators can leverage technology to enhance their maintenance protocols. The integration of IoT technology enables predictive maintenance, where sensors monitor valve performance continuously. This allows for the identification of potential issues before they lead to failures, scheduling maintenance only when necessary and reducing downtime in production environments.

Proportional valves play a pivotal role in the advancement of industrial technologies. Their ability to facilitate accurate control of fluid dynamics provides significant advantages, enhancing the efficiency, safety, and reliability of operations across various sectors. As industries continue to advance, the importance and implementation of proportional valves are likely to increase, ensuring their presence as a fundamental component in automated and complex systems.

Looking forward, ongoing research and development are expected to yield even more innovations in proportional valve technology. Investigations into artificial intelligence for adaptive control strategies, further improvements in materials sciences, and the integration of renewable energy systems into valve operation are just a few anticipated advancements. The future promises increasingly sophisticated solutions that drive industrial applications forward, with proportional valves at the forefront of this evolution.

Ultimately, the exponential advancements in proportion control technologies underline the significance of these valves in shaping the future of modern industry, underlining their role not only in enhancing current processes but also in paving the way for new applications and solutions that challenge traditional methodologies.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!