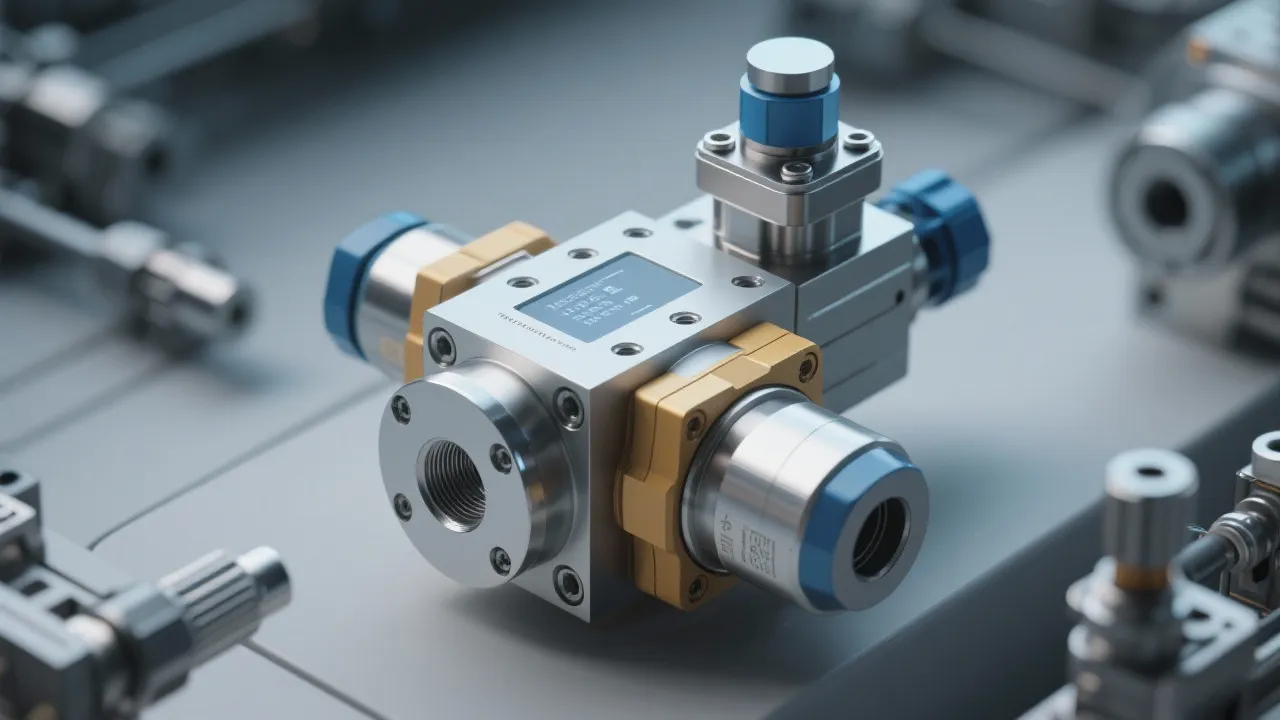

Proportional valves play a pivotal role in the automation and control systems within industries. These sophisticated devices enable precise control of fluid flow, thereby crucially influencing the efficiency and safety of various applications. From basic functionalities to their integration in complex systems, proportional valves ensure optimal operation in modern industrial settings.

In the realm of industrial automation and control systems, proportional valves are instrumental components that enable precise adjustment of fluid flow and pressure. Unlike traditional on/off valves, proportional valves can modulate flow in a continuous manner, offering finer control and increased efficiency in systems such as hydraulics and pneumatics. Their role is pivotal in any automated process where variable positioning or pressure regulation is required, enhancing both productivity and performance.

Proportional valves operate by using a solenoid to control the degree of valve opening, which in turn adjusts the flow rate and pressure within the system. Their ability to provide variable output in response to changes in input makes them suitable for a wide range of applications including manufacturing, automotive, and process industries where dynamic and accurate adjustments are critical. This feature allows proportional valves to be utilized in environments where precision is paramount, such as robotic assembly lines, CNC machinery, and even in the medical field for equipment like IV pumps and infusion systems.

One of the major benefits of utilizing proportional valves is their capability to enhance system performance by providing continuous control rather than binary operations. This results in more stable operations, minimized wear and tear due to reduced mechanical stress, and increased operational lifespan of the machinery. Additionally, the energy consumption can be significantly reduced since the valves adjust flow and pressure based on real-time requirements, leading to cost savings over time. Furthermore, the improved responsiveness of these valves supports advanced manufacturing techniques such as just-in-time production and lean manufacturing principles, which strive for efficiency and waste reduction.

According to experts in the field, advances in material science and electronics have significantly enhanced the performance attributes of proportional valves. There is an active trend towards miniaturization, resulting in more compact and efficient designs. Additionally, the integration of smart technologies is paving the way for automated and remote operation capabilities. This trend includes the incorporation of IoT (Internet of Things) functionality, allowing for real-time data collection, remote diagnostics, and predictive maintenance capabilities, which further enhance reliability and operational uptime.

| Aspect | Proportional Valve | Traditional Valve |

|---|---|---|

| Control | Variable, continuous | Binary, on/off |

| Efficiency | High, with smooth adjustments | Moderate, discrete control |

| Applications | Complex, dynamic systems | Simple, static systems |

| Cost | Higher due to advanced features | Lower initial outlay |

While the benefits are substantial, integrating proportional valves can be challenging due to their complex nature and the precision required in their operation. Ensuring compatibility with existing systems, achieving seamless communication between components, and maintaining the calibration are some of the common hurdles faced during integration. Moreover, the technical knowledge required for managing these components sometimes necessitates specialized training for maintenance personnel.

The performance metrics of proportional valves can be characterized by various parameters that significantly influence their effectiveness in an application. These parameters help in evaluating how well a proportional valve is likely to perform in real-world conditions, guiding choices in high-stakes industrial applications.

As industries evolve, the demands for automation and efficiency in processes continue to rise. The future of proportional valve technology is being shaped by innovations that address these challenges. Emerging trends indicate a move toward incorporating enhanced feedback systems, allowing valves not only to receive commands but also to send data back to control systems, facilitating predictive maintenance and overall system optimization.

Learning from real-world applications can further illuminate the practical advantages of integrated proportional valves. Here are a couple of case studies showcasing their successful deployment across different sectors:

In an automotive manufacturing plant, proportional valves were implemented in robotic assembly lines to control the application of adhesives during the vehicle assembly process. By replacing traditional on/off valves with proportional valves, the plant was able to achieve precise control over adhesive flow rates. This resulted in reduced material wastage and enhanced quality assurance, as the precise application has led to fewer production errors.

A leading food processing company transitioned to proportional valves in their mixing and filling stations. The ability to achieve consistent and precise flow rates meant that they could maintain the exact ingredient specifications required for their products. The operational efficiencies gained not only improved product quality but also reduced downtime, allowing for faster production cycles, which directly correlated to increased profitability.

Proportional valves are vital components in modern industrial systems, providing advanced control features that enhance overall performance, efficiency, and safety. As technology continues to evolve, the capabilities and applications of these valves expand, positioning them as an integral part of future industrial automation solutions. The widespread adoption of these valves in various sectors reflects their importance in meeting the demands of precise control in an increasingly automated world.

The journey of proportional valve technology illustrates the balance between complexity and efficiency in modern manufacturing and automated systems. By investing in the right technologies, companies can enjoy significant returns in operational efficiency, safety, and product quality. Understanding the capabilities, applications, and future prospects of proportional valves remains critical for businesses looking to thrive in an increasingly competitive landscape.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!