Proportional valves are crucial in controlling fluid flow across numerous industries, ensuring precise regulation and efficiency. These valves adjust flow or pressure smoothly, responding to varying demands. Proportional valves are designed for applications requiring fine control and adaptability in fluid dynamics, playing a pivotal role in modern automated systems.

Proportional valves are essential components in fluid control systems, widely utilized across various industries to regulate the flow and pressure of liquids and gases. Unlike traditional on/off valves, proportional valves offer a variable output that can be precisely adjusted to meet specific requirements. This adaptability makes them highly sought after in applications where the controlled delivery of fluids is critical. As industries evolve and demand for refined control systems increases, the reliance on proportional valves continues to grow, marking them as a cornerstone technology in sectors ranging from automotive to aerospace.

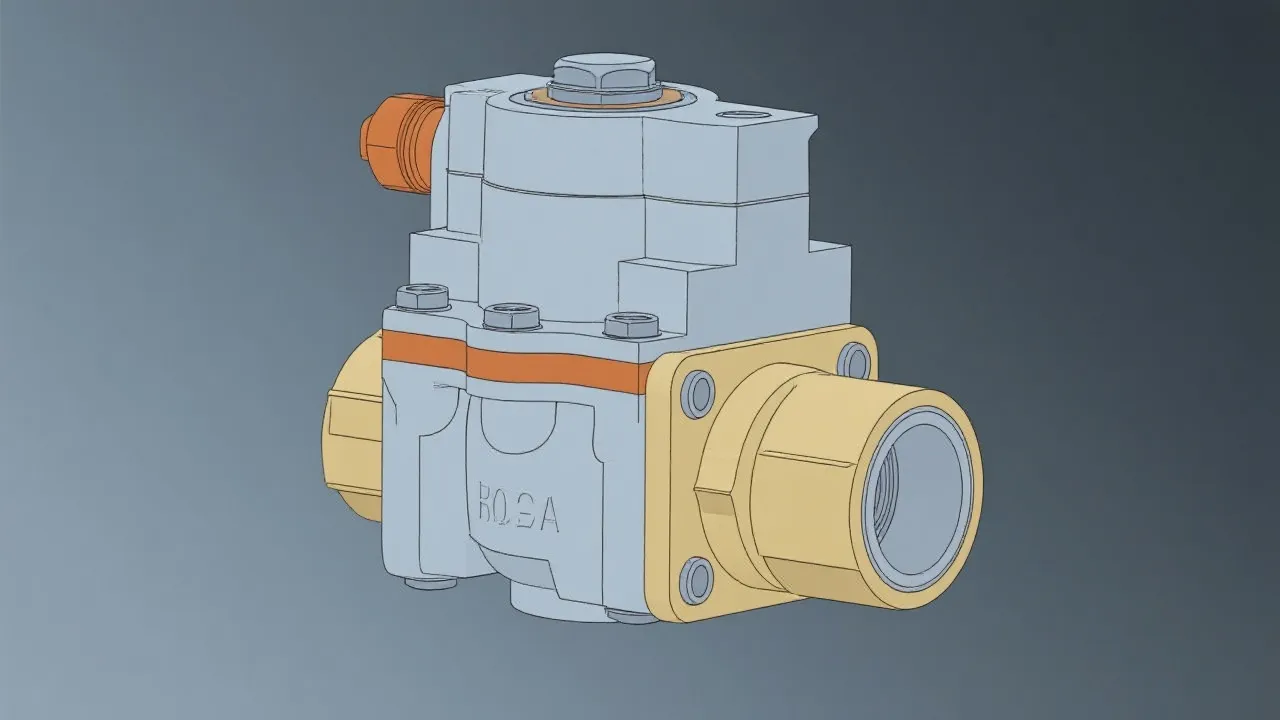

Proportional valves function by converting an electronic input signal into a mechanical output, adjusting the valve position to control fluid flow. The key advantage is their ability to provide fine-tuned flow adjustment, making them ideal for applications requiring varying levels of fluid control. This is achieved through advanced electronics and feedback systems that maintain accurate valve positioning. The operation of a proportional valve can often be attributed to three main components: the actuator, the sensor, and the controller. The actuator adjusts the flow by changing the valve's position based on signals from the controller, which interprets data from the sensor monitoring the flow and pressure.

For example, consider a hydraulic system that operates machinery on a production line. A proportional valve allows for the fluid flow to the actuators within the machinery to be adjusted based on real-time feedback about the load and speed requirements. By precisely controlling the flow, the proportional valve ensures that the machinery operates smoothly, efficiently, and with maximum energy savings, prioritizing performance and minimizing waste.

The versatility of proportional valves makes them suitable for a range of industrial applications. In the automotive industry, they are used to regulate fuel flow and emissions. For instance, in modern fuel injection systems, proportional valves help in managing the amount of fuel injected into the engine, resulting in better fuel efficiency and lower emissions. This is critical in meeting stringent automotive regulations and improving the performance of vehicles.

Manufacturing sectors benefit from their precision in controlling the movement of hydraulic fluids, optimizing the efficiency of machinery and reducing energy consumption. From CNC machines to robotic arms, proportional valves are integral in adjusting the speed and force applied by these machines, enhancing productivity and precision during manufacturing processes.

In the aerospace industry, where fluid control is crucial, proportional valves are utilized in flight systems for precise control of hydraulic flight control surfaces. This improves aircraft maneuverability and overall performance. Similarly, in the energy sector, particularly in renewable energy applications like wind and solar, proportional valves help manage fluid flow in hydraulic systems, optimizing energy extraction and conversion processes. By ensuring that the right amount of hydraulic fluid is used at any given time, these valves significantly enhance the efficiency and reliability of energy systems.

The precise control offered by proportional valves results in significant benefits, including enhanced performance of machinery, reduction in energy costs, and improved safety. Their capability to deliver variable flow rates ensures smooth operation and reduces wear and tear on systems, increasing the lifespan of equipment. In addition, the adaptability of proportional valves allows for seamless integration into existing systems, reducing the need for extensive redesign or modification, which can save both time and money during installation.

Moreover, the feedback mechanisms employed by proportional valves enable real-time monitoring of fluid dynamics. This capability not only enhances operational control but also aids in predictive maintenance, allowing for potential issues to be detected before they result in system failures. By transitioning from reactive to proactive maintenance strategies, businesses can minimize downtime and extend the service life of their equipment significantly.

Additionally, the implementation of proportional valves contributes to sustainability efforts. By optimizing fluid usage and energy consumption, these valves help organizations lower their environmental footprint. Many companies are increasingly focused on sustainability and social responsibility, and adding energy-efficient components like proportional valves aligns with these corporate goals, ultimately bolstering their market position and reputation.

| Feature | Proportional Valves | On/Off Valves |

|---|---|---|

| Control | Variable, precise control of flow and pressure | Binary control: fully open or closed |

| Applications | Suitable for systems requiring frequent adjustments | Ideal for simple, non-variable systems |

| Energy Efficiency | High, due to optimized flow management | Lower, energy wastage from non-optimized flow |

| Failure Impact | Gradual performance degradation, easier to manage | Sudden operational failure, creating risks |

| Installation Complexity | Higher complexity, requires integration with control systems | Lower complexity, easier integration |

| Cost | Higher initial investment | Lower initial investment |

Despite their advantages, the implementation of proportional valves can present challenges. These include the initial cost of installation, the complexity of integration into existing systems, and the need for regular maintenance to ensure optimal performance. For companies implementing proportional valves for the first time, the learning curve associated with understanding their advanced functionalities may also pose a challenge. Staff may require additional training to adapt to the new control paradigms and maintenance procedures, which can temporarily hinder productivity during the transition phase.

Moreover, proportional valves often require more sophisticated control systems than their on/off counterparts. This increased complexity might necessitate upgrading existing control software or hardware, which adds to the initial cost and time required for implementation. Additionally, the dependency on electronic components means that proportional valves might be susceptible to electronic failures or issues related to signal processing, highlighting the importance of having a robust maintenance and troubleshooting system in place.

However, the good gains in efficiency and cost savings often justify these initial investments. Identifying and addressing potential challenges before implementing proportional valves are crucial steps to ensure a successful transition. By developing a comprehensive plan, organizations can minimize disruptions and capitalize on the numerous benefits that these valves provide.

Recent advancements in proportional valves focus on enhancing their adaptability and responsiveness. One significant area of development is the integration of IoT (Internet of Things) capabilities, which allows valves to communicate with other devices and systems for real-time monitoring and control. IoT-enabled proportional valves can remotely adjust fluid flow based on data collected from various sensors within the system, giving operators more precise control over the fluid dynamics.

These smart valves come equipped with features such as self-diagnostics and predictive analytics, which can automate performance evaluation and maintenance scheduling. For instance, if a valve begins to show signs of wear or a decrease in performance, the system can alert operators before it leads to a system failure, allowing for timely maintenance. This proactive approach can significantly reduce operational downtime and maintenance costs.

With the rise of Industry 4.0, proportional valves are becoming part of larger automated systems where data analytics play a crucial role in decision-making. By using machine learning algorithms, organizations can optimize the performance of their entire fluid control system over time, adjusting parameters based on historical performance data and predictive modeling.

Additionally, advancements in materials technology are yielding lighter, more durable valve components, further enhancing the efficiency of proportional valves. These new materials can resist corrosion and wear, ensuring longer service life and reduced maintenance frequency. This technological evolution demonstrates how proportional valves are evolving not just in function, but also in reliability and sustainability, aligning with modern industrial needs.

Proportional valves are indispensable in modern fluid control, offering unmatched precision and versatility. Their integration in various sectors not only enhances operational efficiency but also contributes to significant cost savings and sustainability. As technology advances, the role of proportional valves is expected to expand, further revolutionizing industrial fluid dynamics. The continuous evolution of these valves, driven by innovation in materials and technology, ensures that they remain relevant and effective in meeting the demands of modern industries.

With their ability to adapt to real-time data and integrate seamlessly with automated systems, proportional valves are paving the way for a more interconnected and efficient future in industrial operations. Companies that embrace these advancements will not only benefit from enhanced operational capabilities but will also position themselves as leaders in efficiency and sustainability within their respective markets.

Furthermore, as more industries recognize the critical role of fluid management in ensuring operational efficiency, the demand for proportional valves is expected to grow. This growth will likely spur further innovations, leading to the development of even more advanced proportional valve technologies that will shape the future landscape of industrial controls.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!