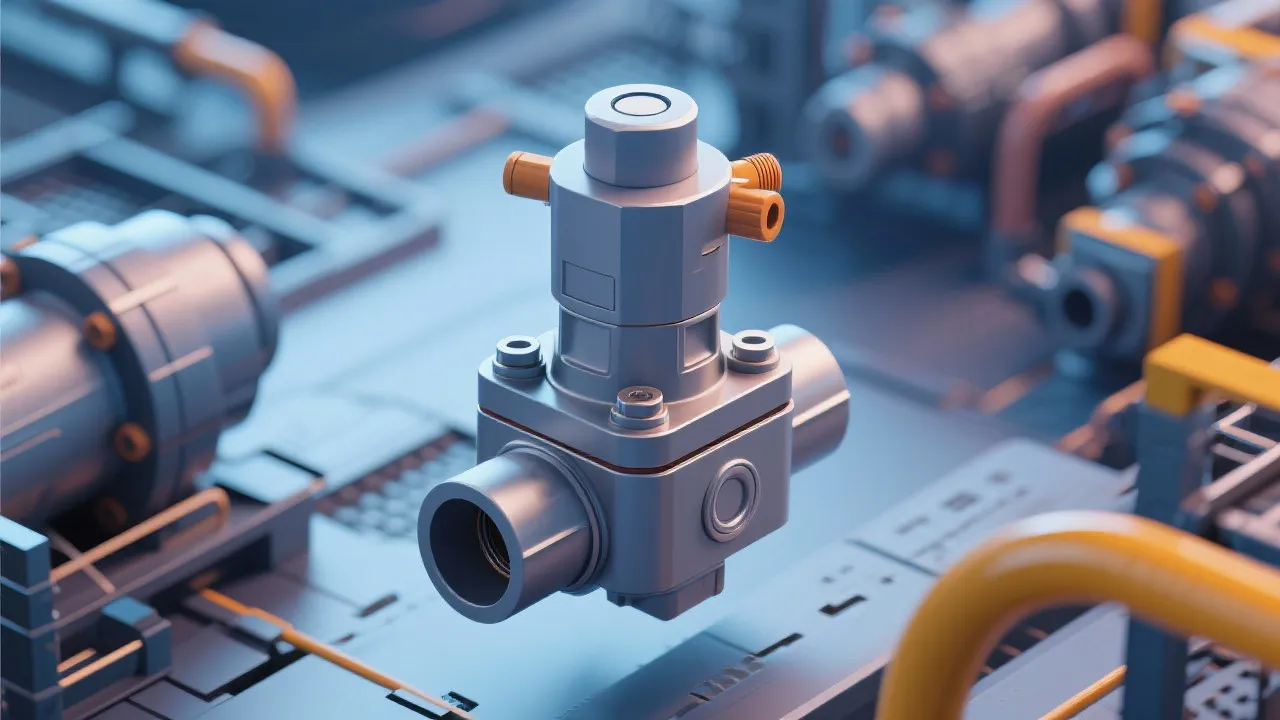

Proportional valves are essential components in industrial systems, allowing precise control of fluid flow and pressure. These devices are renowned for their adaptability in various applications, from manufacturing automation to fluid power systems. Their ability to modulate flow makes them indispensable for enhancing efficiency and performance across diverse industries.

The proportional valve stands as a cornerstone in the industrial sector, especially in systems where precise control of fluid flow and pressure is paramount. These components are highly instrumental in maintaining precision in processes that involve variable fluid control, ensuring optimal performance and efficiency. As technology continues to evolve, the role of proportional valves has expanded, adapting to the increasingly intricate demands of modern engineering applications. From simple hydraulic systems to complex automated machinery, proportional valves play a pivotal role in ensuring effective operation across a broad array of contexts.

Proportional valves offer a significant edge over traditional on/off valves, primarily due to their ability to adjust the flow rate or pressure in an infinitely variable manner. This adaptability translates into:

Moreover, proportional valves can enhance the lifespan of other components within a system by reducing the wear and tear that can result from abrupt changes in flow and pressure. This not only contributes to the overall reliability of the machinery but also signifies a reduction in maintenance costs and downtime associated with unexpected failures. The incorporation of smart technology into these valves further amplifies their advantages, permitting real-time adjustments based on system demands.

The working mechanism of a proportional valve is straightforward yet sophisticated. The valve consists of key components such as the actuator, the controller, and the valve element. Their harmony allows for seamless fluid adjustment, which is crucial in applications requiring granular control of operational parameters. The actuator often responds to electrical signals from a controller, manipulating the valve element to increase or decrease fluid flow as needed.

The intricacies of these components deserve a deeper look:

This interplay of components ensures that proportional valves can quickly adapt to changing conditions, making them ideal for dynamic systems. The effective integration of these elements enables precision fluid control, allowing systems to respond efficiently and accurately to varying operational demands.

| Feature | Proportional Valves | Traditional Valves |

|---|---|---|

| Control Type | Variable (Continuous) | On/Off (Discrete) |

| Precision | High precision control | Limited precision |

| Energy Efficiency | Energy-efficient | Typically less efficient |

| Typical Applications | Industries with dynamic requirements | Basic applications with binary needs |

Another significant distinction is the adaptability of proportional valves to varying flow conditions. Unlike traditional valves that either permit or block flow, proportional variants can modulate flow rates, making them invaluable in systems where demand is subject to fluctuations, such as in chemical processing or automotive applications. Traditional valves may suffice for simpler systems, but as requirements evolve towards greater efficiency and control, the advantages of proportional valves become more pronounced.

Proportional valves find their place in various industries:

The adaptability of proportional valves allows for innovative applications, such as in renewable energy, where they help to optimize fluid movement in solar thermal energy systems or hydroelectric plants. As industries continue to evolve towards automation and smart technologies, the demand for proportional valves will undoubtedly increase, underscoring their significance across multiple sectors.

When selecting a proportional valve, consider the following criteria:

Understanding these parameters will significantly aid in selecting a proportional valve that not only meets immediate needs but also aligns with future system expansions or modifications, ensuring long-term viability and operational success.

Despite their myriad advantages, using proportional valves can present challenges such as:

Mitigation strategies include regular training for technicians and scheduled maintenance protocols. Additionally, manufacturers often provide detailed operational manuals and training resources that can help in easing the installation and maintenance burdens. Regularly revisiting operational data and performance logs can also help identify potential issues before they lead to significant failures, ensuring that any decline in function is addressed promptly.

In addition, investing in better technology such as smart sensors can facilitate predictive maintenance by providing real-time monitoring capabilities that alert operators to issues before they become critical. Proper documentation and understanding of the specific requirements for proportional valves can make transitioning easier and more efficient, thereby enhancing safety and performance in operational settings.

Understanding and implementing proportional valves can significantly enhance operational efficiency within various industrial applications. Their capacity for precise control and flexibility across different settings makes them indispensable tools for modern engineering solutions. As industries increasingly recognize the importance of precision control and energy efficiency in their operations, the reliance on such advanced components will undoubtedly continue to rise.

Furthermore, advancements in proportional valve technology, such as the integration of smart connectivity and enhanced materials for durability and corrosion resistance, hint at a future where these valves will become even more sophisticated. Moving forward, as organizations continue adopting automation and smart technologies, the innovations surrounding proportional valves will play a crucial part in advancing industrial efficiency and productivity. In an era where energy conservation and operational excellence are paramount, proportional valves stand as a testament to the ongoing evolution of fluid control technologies that empower industries to meet their goals in an environmentally conscious manner.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!