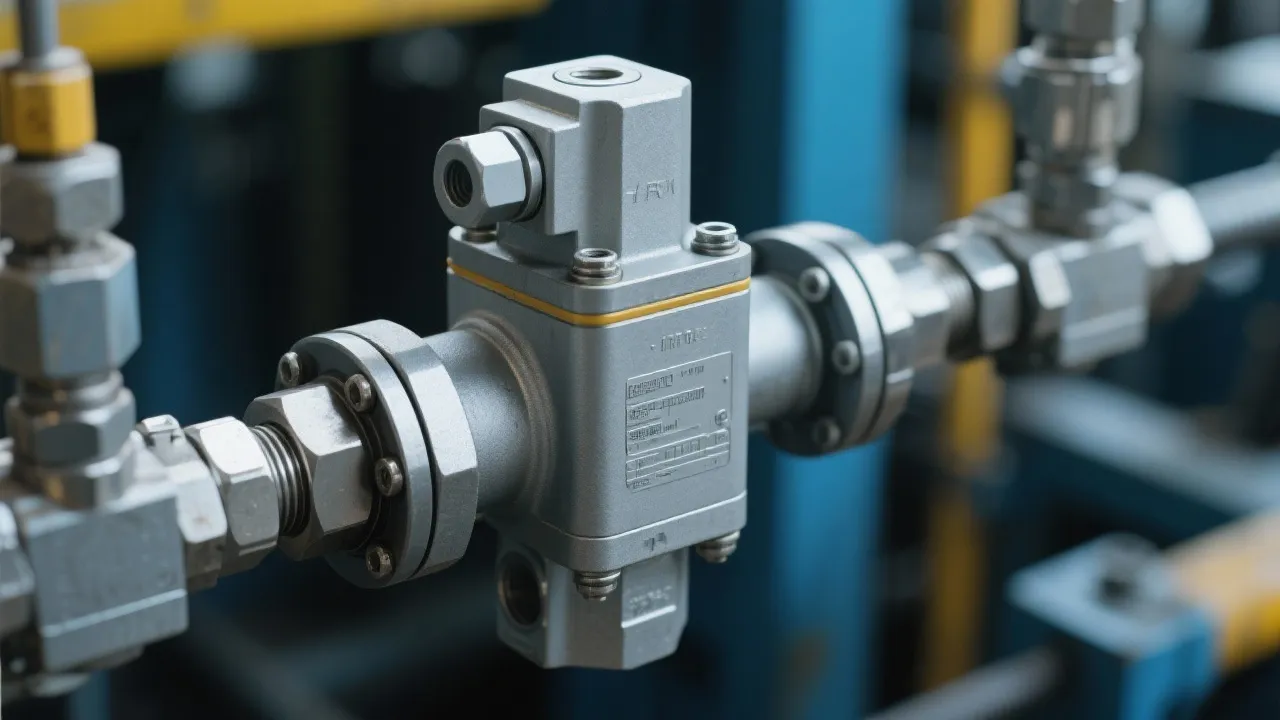

This guide delves into the intricacies of proportional valves, essential components in fluid control systems. Proportional valves regulate the flow and pressure of fluid in various applications, providing precise control essential for modern automation and industrial processes, as they bridge the gap between digital control and analog output.

In the realm of fluid control systems, proportional valves have emerged as a critical component, revolutionizing how industries manage the flow and pressure of liquids and gases. These sophisticated devices offer precise control, a necessity for modern automation and industrial processes. This article aims to explore the depths of proportional valves, examining their function, application, and impact on various industries. As the need for enhanced automation and efficiency rises across various sectors, understanding the role of proportional valves becomes crucial for engineers, technical experts, and industry professionals alike.

Proportional valves, unlike traditional on/off valves, allow for the continuous modulation of flow and pressure, thanks to their electronic control capabilities. These valves operate by receiving a signal that corresponds with the desired output flow or pressure level. The internal mechanics adjust accordingly, ensuring the output matches the intended parameters. This capability makes them invaluable in systems requiring high precision, such as in aerospace, automotive, and manufacturing sectors. The control signal can be derived from various inputs, including pressure transducers, flow meters, or even higher-level controllers such as PLCs (Programmable Logic Controllers), leading to a dynamic response that is not possible with conventional on/off regulation.

Proportional valves are pivotal in sectors requiring nuanced control over fluid movement and pressure. For example, in the automotive industry, they play a crucial role in systems such as brake control and fuel management. In manufacturing, their precision aids in processes that demand exact fluid dispensation, reducing waste and enhancing efficiency. Notably, the incorporation of proportional valves in hydraulic systems can significantly improve operational safety and responsiveness, leading to enhanced productivity. Furthermore, in industries such as pharmaceuticals and food processing, where maintaining specific conditions is vital, proportional valves help ensure compliance with stringent regulatory requirements, thereby enhancing product safety and quality.”

Proportional valves consist of several key components, including a spool, solenoid, and control electronics. The solenoid generates a magnetic field that moves the spool, enabling the adjustment of flow or pressure. The efficiency of this process is further enhanced by using advanced materials and engineering designs that allow for minimized friction and improved sensitivity. There are various types of proportional valves, including proportional pressure relief valves, proportional directional valves, and proportional flow control valves, each tailored for specific applications. By selecting the appropriate type, industries can optimize system performance in line with their unique operational demands.

| Type | Function |

|---|---|

| Proportional Pressure Relief Valve | Controls and limits the pressure to a set point to ensure system safety. |

| Proportional Directional Valve | Regulates the direction of fluid flow within the system. |

| Proportional Flow Control Valve | Allows for precise control of the rate of fluid flow. |

The applications of proportional valves are vast and varied. In the aerospace sector, they manage hydraulic and pneumatic systems with high reliability. These valves ensure that flight control surfaces respond predictively to pilot inputs, enhancing aircraft stability and safety. In industrial automation, they enable fine control over robotic movements and machining processes, ensuring consistent product quality. For instance, in CNC (Computer Numerical Control) machines, proportional valves help maintain steady coolant flow, resulting in optimal cutting conditions and tool longevity. Moreover, they are instrumental in chemical processing plants where precise chemical ratios are crucial; a slight deviation could lead to unacceptable quality or safety hazards. In addition to this, proportional valves are used in medical equipment, where they regulate the flow of gases or liquids used in various treatments, signifying their importance beyond traditional industrial applications.

With the advent of sophisticated electronic control systems, proportional valves have seen significant advancements. Modern versions offer improved response times, enhanced durability, and expanded functionalities, thanks to integrated sensors and intelligent feedback systems. These innovations have broadened their application scope and boosted their reliability in critical operations. For instance, smart proportional valves can communicate with other devices in real time, allowing for adaptive adjustments based on changing conditions in the fluid system. Additionally, the development of digital signal processing technologies has led to enhanced precision in control algorithms, further optimizing the performance of these valves. The integration of Internet of Things (IoT) technology into proportional valve systems allows for remote monitoring and troubleshooting, paving the way for predictive maintenance strategies that minimize downtimes and operational interruptions.

Despite their numerous advantages, proportional valves must be carefully selected and maintained to maximize their performance. Factors such as the compatibility of valve materials with the fluids in use, the operational environment, and the required level of control precision must be considered. For instance, choosing a valve that may corrode when exposed to specific chemicals could lead to significant failures. Moreover, environmental factors such as temperature, humidity, and potential exposure to dust or contaminants can drastically affect performance. Regular monitoring and maintenance are pivotal to prevent wear and ensure longevity, often requiring specialized knowledge and skills from personnel. Failure to address these considerations can lead to decreased efficiency, increased operational costs, and even severe safety hazards within the fluid control systems.

Real-world applications of proportional valves illustrate their significance and effectiveness in various industries. One notable instance occurred in an automotive manufacturing plant where traditional pneumatic valves were replaced with proportional valves for assembly line automation. The results included a 20% improvement in cycle time due to precise control over pneumatic actuators, leading to higher throughput and greater operational efficiency. Additionally, the reduced air consumption resulted in lower energy costs, evidencing the economic advantages of investing in such technology.

In another case, a pharmaceutical company implemented proportional flow control valves in its chemical mixing process. By utilizing precision dosing, the company was able to maintain stringent control over the ratios of active ingredients, thereby ensuring product consistency and regulatory compliance. The improved control also minimized waste, translating into substantial cost savings and a more sustainable operation. This example not only highlights the economic benefits but also emphasizes the critical role of precision in industries where compliance with safety standards is paramount.

The future of proportional valves is poised for further innovations driven by advancements in technology and a growing focus on automation. As industries place increased emphasis on efficiency and process optimization, the development of next-generation proportional valves will likely center around their adaptability and integration with smart manufacturing practices. Trends such as machine learning and artificial intelligence are anticipated to refine the operational capabilities of proportional valves, enabling even greater precision in fluid control systems.

Moreover, the emergence of renewable energy technologies is set to stimulate demand for proportional valves in applications involving alternative energy sources. For instance, the wind energy sector is utilizing proportional valves in pitch control systems for turbine blades, maximizing energy capture while minimizing mechanical stress. Such applications will undoubtedly bring about increased reliability and efficiency in energy systems worldwide.

The shift towards sustainable practices will also motivate manufacturers to innovate materials for proportional valves, focusing on reducing environmental impacts. Efforts may include the development of biocompatible materials for surgical applications, or the use of recyclable components in industrial valves to meet growing environmental regulations. As the landscape continues to shift, the role of proportional valves will expand, adapting to the new challenges and requirements of an evolving global market.

As industries continue to advance, the demand for accurate and efficient fluid control systems will only grow, solidifying the role of proportional valves. With ongoing innovations further enhancing their capabilities, these valves will continue to be at the forefront of industrial automation, driving efficiency and precision. Ultimately, the integration of proportional valve technology within an array of sectors supports enhanced performance and sustainability of operations, thereby fostering modern advancements in fluid dynamics and control. With future developments likely enhancing both operational efficiency and environmental sustainability, the role of proportional valves is set to become even more vital in both established and emerging industries.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!