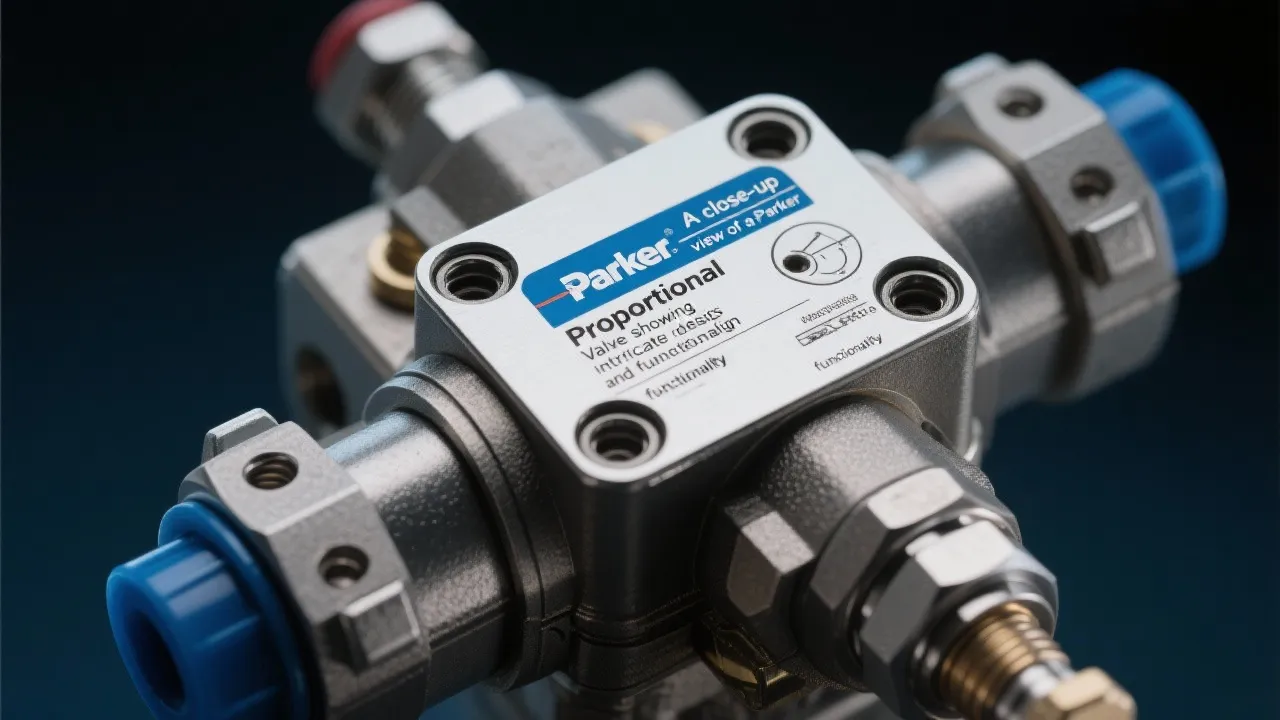

This guide explores the significance and application of the Parker Proportional Valve in various industries. Known for its precision and efficiency, the Parker Proportional Valve plays a crucial role in fluid control systems, providing enhanced performance and control. Designed for specific industrial applications, it contributes significantly to system efficiency and reliability.

Parker Proportional Valves are instrumental in modern industrial applications, renowned for their precision and adaptability in fluid control systems. Employed across a multitude of sectors, these valves ensure optimal performance, accurate regulation of flow rate, and pressure in hydraulic and pneumatic systems. With the evolution of technology driving industries towards greater efficiency and performance, these valves have become a cornerstone in achieving those goals.

The significance of Parker Proportional Valves lies in their ability to provide precise control, which is critical in environments where exact fluid dynamics can impact operational efficiency and safety. Industries such as aerospace, automotive, and manufacturing extensively rely on these components to maintain high standards of productivity and compliance. For instance, in aerospace applications, maintaining accurate cabin pressure and environmental conditions is vital for passenger safety. Similarly, automotive applications demand precise control of hydraulic systems to ensure optimal performance and responsiveness.

Moreover, in the manufacturing sector, these valves play a pivotal role in processes ranging from injection molding to sheet metal forming, where the control of pneumatic and hydraulic pressures directly influences product quality and production efficiency. The versatility of Parker Proportional Valves makes them indispensable in manufacturing complex systems that require a high level of reliability and precision control for effective operation.

At the heart of a Parker Proportional Valve's utility is its ability to offer variable output in response to input signals, which allows a finely tuned control over fluid parameters. This distinguishes it from standard on/off valves that lack this level of control. Additionally, Parker Proportional Valves incorporate advanced technology, such as electronic controls and sensors, that enable real-time monitoring and adjustment of valve performance. These features contribute to reduced system wear, extended service life, and heightened safety measures.

Furthermore, its robust construction ensures durability and minimal maintenance requirements, making it a cost-effective choice in the long run. The valves are designed to operate under extreme conditions, resisting wear from abrasive particles and maintaining operational integrity in the face of temperature fluctuations and varying fluid qualities. These core features make Parker Proportional Valves a reliable choice for any demanding application.

Working seamlessly with electronic control systems, Parker Proportional Valves are integral in automated processes. In robotics, for instance, they precisely modulate fluid power to perform sensitive tasks with high precision. Such tasks may include robotic arm movement in assembly lines, where accuracy and repeatability are crucial. Similarly, in the automotive sector, they are critical in systems requiring reliable modulation of numerous hydraulic parameters, such as in the functioning of brake systems, steering mechanisms, and suspension systems.

Additionally, industrial machinery, such as CNC machines, depend on precise fluid control for optimal operation. Here, Parker Proportional Valves allow for nuanced movements, resulting in high-quality finishes and reducing scrap rates. The ability of these valves to interface effectively with sophisticated control algorithms is a game-changer, leading to overall improvements across machinery and production lines.

From an expert perspective, the operational efficiency of Parker Proportional Valves is attributed to their sophisticated electro-hydraulic interface. By converting electrical signals into fluid power modulation, they provide nuanced control levels across a wide range of applications. This capability is especially valuable in environments where precision is paramount.

For instance, the electro-hydraulic system allows for rapid adjustments in flow and pressure, which is critical in dynamic systems where operational parameters may shift rapidly. Experts note that the integration of programmable control units allows operators to change valve characteristics on the fly, adapting to evolving process demands. Furthermore, advanced feedback mechanisms can alert operators to potential issues before they manifest, ensuring preventive maintenance and reducing downtime.

| Type | Advantages | Limitations |

|---|---|---|

| Parker Proportional Valve | Precise control, durable, energy-efficient, versatile integration options | Higher initial cost compared to standard valves; requires informed installation and maintenance |

| Standard On/Off Valve | Simple design, low cost, easy to install | Lacks precision, more wear and tear, less energy-efficient |

| Electro-Hydraulic Valve | High precision, good response times | Complex operating mechanisms can lead to higher servicing costs |

| Flow Control Valve | Excellent for maintaining steady flow rates | Less effective for applications requiring variable output |

Installing Parker Proportional Valves requires meticulous attention to detail, ensuring all electronic and mechanical connections are secure and aligned with system specifications. A well-planned installation process will prevent future operational issues and enhance the overall efficiency of the system. Proper alignment with hydraulic or pneumatic piping and ensuring that the electrical connections are intact is critical. It’s advisable to work with qualified technicians who understand the specific needs of Parker’s products and the intricacies involved in implementing them effectively within various systems.

Regular maintenance involves checking for signal integrity and mechanical wear, ensuring the valve continues to operate efficiently. Technicians should routinely monitor the valve’s performance and look for signs of wear, such as unusual noises or fluctuating readings. Cleaning and calibrating the valves periodically can prolong their lifespan and maintain the level of performance expected from Parker products. Furthermore, it is beneficial to maintain a detailed maintenance log which tracks inspections and any adjustments made over time, allowing operators to see historical performance trends and anticipate potential issues.

In summary, Parker Proportional Valves represent an essential component for those seeking refined control within fluid systems, delivering efficiency, reliability, and precision that meets the dynamic challenges of modern industrial operations. Their adaptability across various industries ensures they remain a staple in the pursuit of enhanced productivity and sustainability. As industries adopt smarter technologies and aim for optimal operation, the capabilities provided by Parker Proportional Valves will undoubtedly play a crucial role in navigating these advancements.

Additionally, understanding the evolving nature of these technology-driven environments emphasizes the importance of embracing innovation in fluid control systems. The future of industrial automation appears bright, especially with Parker Proportional Valves paving the way toward more intelligent, efficient, and responsive systems.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!