This article delves into the vital role of the 7805 heatsink in electronics, focusing on its functionality in managing heat dissipation to protect the 7805 voltage regulator. Proper use of a heatsink is critical for maintaining component efficiency and lifespan. We provide expert insights into choosing the right heatsink, addressing common questions, and understanding its impact in electronic systems.

The 7805 heatsink is an essential component in electronics, particularly when deploying the 7805 voltage regulator. As electronic systems become more complex and compact, effective thermal management becomes crucial. The heatsink serves to dissipate the heat generated by the voltage regulator, ensuring it operates within safe temperature limits to prevent damage or performance degradation.

The role of the 7805 heatsink cannot be overstated. In many electronic applications, the reliability and lifespan of the voltage regulator directly impact the overall performance of the device. Therefore, it is necessary to employ adequate thermal management solutions to maintain functionality.

When the 7805 regulator is in operation, it can reach temperatures high enough to affect its performance and reliability. As a linear voltage regulator, the 7805 produces heat through the conversion of input voltage to a stable output voltage, and this heat must be effectively dissipated to ensure the longevity of both the regulator and the entire electronic device. A robust heatsink increases the contact surface area, allowing for more efficient heat flow away from the component and helping maintain optimal performance.

Electronic components, especially those involved in power regulation such as the 7805, generate heat during operation. Excessive heat can lead to a range of problems, from reduced efficiency and premature failure to complete breakdown of the device. Integrating a heatsink provides a passive thermal management solution, allowing heat to be conducted away from the device and released into the surrounding environment.

The phenomenon of heat generation is inherent in all electronic circuits, but linear regulators like the 7805 are particularly prone to producing significant amounts of heat as they step down voltage. The efficient operation of electronic systems relies heavily on preventing thermal accumulation. Heat dissipation mechanisms, such as heatsinks, lower the overall temperatures of critical components, thus preventing thermal runaway, a situation where increased temperature causes further increases in heat generation, potentially resulting in device failure.

Moreover, efficient heat dissipation improves the effectiveness of thermal design. It allows engineers to optimize the layout and arrangement of electronic components on a PCB (Printed Circuit Board), making better use of space and reducing energy losses during operation. This aspect is significant as electronics become smaller and more integrated, requiring meticulous planning regarding thermal management.

When choosing a heatsink for your 7805 voltage regulator, consider the following factors: thermal resistance, material, size, and mounting method. The thermal resistance should match the power dissipation of the 7805 to maintain its temperature within operational limits. Common materials include aluminum, known for its excellent thermal conductivity and lightweight nature. The size and mounting method must also align with the physical constraints and configuration of your circuit board.

Thermal resistance is defined as the measure of a material's ability to resist heat flow. In selecting a heatsink, the lower the thermal resistance value, the better heat transfer will be facilitated from the 7805 voltage regulator to the surrounding air. A heatsink with high thermal resistance will not efficiently conduct heat away, leading to higher operating temperatures and potentially impacting performance and reliability.

Material choice is crucial as well; aluminum is popular due to its high thermal conductivity, which allows for efficient heat transfer with a relatively low weight, making it suitable for a variety of applications. Other materials such as copper provide even better thermal conductivity but are heavier and more expensive. It's essential to consider these trade-offs when selecting a heatsink material.

In terms of size, the heatsink must fit within the space available in the device while ensuring sufficient airflow around it. This is vital in environments where space is constrained, as a larger heatsink can provide better heat dissipation but may not be practical in all designs. The mounting method complements these factors; secure attachment to the regulator using clips, adhesives, or screws promotes optimal heat transfer and prevents unwanted movement that could break contact.

| Criterion | Description |

|---|---|

| Thermal Resistance | Should be low enough to efficiently transfer heat away from the 7805 regulator. |

| Material | Materials like aluminum offer optimal heat conduction properties, while copper can provide superior performance. |

| Size | Must fit within the space available in the device, avoiding obstruction of other components while allowing for proper airflow. |

| Mounting Method | Secure attachment to the regulator using clips, adhesives, or screws for optimal heat transfer without the risk of thermal isolation. |

In addition to these installation steps, consider implementing airflow management around the heatsink. Incorporating fans or utilizing passive cooling strategies, such as strategic component placement, can further enhance the heat dissipation capabilities of your setup.

While selecting the right heatsink is critical, certain techniques can enhance its overall effectiveness. One such method is the application of thermal interface materials (TIMs), which are used between the regulator and the heatsink to reduce thermal resistance. Thermal pastes or pads can significantly improve heat conduction, ensuring heat is dissipated more effectively.

In addition, consider the airflow around the heatsink. The natural convection of air can be enhanced by designing enclosures with strategic air pathways or including fans that improve circulation. Fans can considerably reduce the thermal resistance by increasing airflow across the heatsink, especially in tighter space-constrained environments.

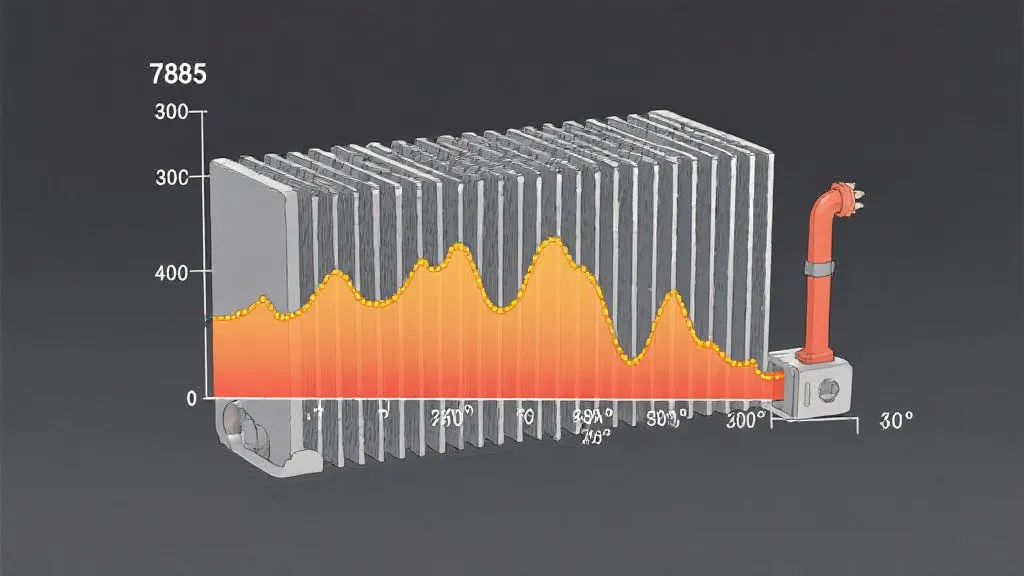

Another aspect to explore is the use of more efficient heatsink geometries. Designs such as fins, which create turbulence in airflow around the heatsink, can further improve cooling efficiency. Using computational fluid dynamics can help optimize heatsink shapes and layouts within a device, leading to significant improvements in thermal management strategies.

Several common pitfalls can negatively affect heatsink performance and thermal management in general. One frequent mistake is not using sufficient thermal paste or applying it incorrectly. An inadequate thermal interface can result in poor heat transfer, leading to higher temperatures. It’s essential to apply an even layer of thermal paste and ensure no air bubbles are present, which could hinder effective heat conduction.

Another common error is underestimating the size of the heatsink. Choosing a heatsink that is too small can lead to overheating and optimal performance issues. It’s vital to calculate the necessary thermal dissipation requirements based on your specific application and load conditions accurately.

Also, overlooking airflow can be detrimental. Many electronic designs fail to consider how heat will dissipate from the heatsink, leading to inefficient cooling. It's important to ensure unobstructed airflow around the heatsink to facilitate effective heat rejection into the ambient environment.

The integration of a proper 7805 heatsink is paramount for the efficient and reliable operation of electronic devices employing voltage regulators. Understanding the criteria for selecting and installing these components ensures better performance and longevity of electronic systems. As technology advances, optimizing every component of a system to maintain thermal balance becomes increasingly critical, making the heatsink an indispensable asset in the world of electronics.

Not only is the correct use of a heatsink vital for performance, but it also significantly influences the design and layout of electronic circuits. As devices continue to get smaller and more complex, thermal management strategies will become even more important. Engineers and designers must involve careful consideration of heat dissipation solutions, including the selection of heatsinks and their integration within the overall design architecture of their projects.

Ultimately, while the 7805 voltage regulator plays a crucial role in voltage stabilization, the effectiveness with which it operates is highly dependent on adequate thermal management. Therefore, adopting best practices for heatsink selection, installation, and airflow management is essential for achieving optimal performance and reliability in electronic applications.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!