The 7805 heatsink is pivotal in dissipating heat from voltage regulators, thus ensuring optimal performance and longevity of electronic circuits. It plays a critical role in maintaining thermal stability and is commonly used in a variety of electronic devices. This article explores the functionalities, applications, and benefits of using a 7805 heatsink, offering insights from industry experts.

In the realm of electronics, maintaining thermal stability is paramount for ensuring the longevity and efficiency of devices. Electronic components are susceptible to a range of environmental factors, but temperature plays a critical role in their performance and durability. Overheating can lead to a range of issues, from temporary malfunctions to complete component failure. A significant aspect of thermal management encompasses the use of heatsinks, which are integral in devices like the 7805 voltage regulator. This article delves into the significance of thermal management, focusing on the 7805 heatsink, its applications, benefits, and best practices for integration in electronic systems.

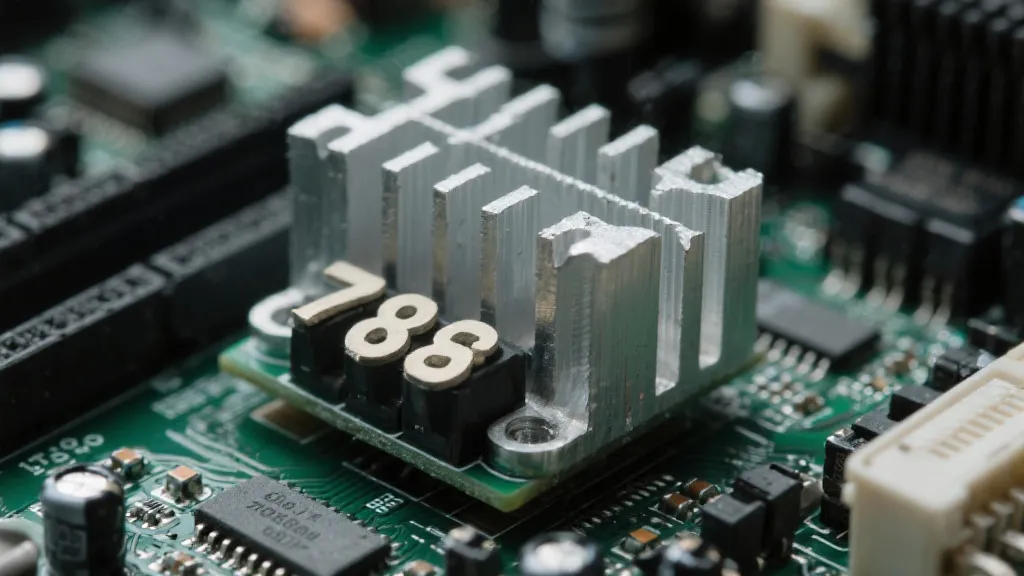

A 7805 heatsink serves as a thermal management solution for the 7805 voltage regulator. The 7805 voltage regulator is a commonly used integrated circuit (IC) that provides a fixed output voltage of 5 volts, essential for powering various electronic circuits. Commonly found in issues ranging from regulating voltage in low-power applications to providing stable power sources in more demanding environments, the 7805 is a reliable choice for engineers. However, during its operation, it generates heat, which if not properly dissipated, can lead to performance degradation or failure. This is particularly crucial in environments with limited airflow or in compact electronic designs. The heatsink acts as a passive cooling device, absorbing and dispersing this heat into the surrounding environment, enabling the 7805 to function within its optimal temperature range.

The primary function of a 7805 heatsink is to enhance the thermal conductivity away from the regulator, effectively cooling it down. This has several benefits:

The 7805 heatsink is utilized in various applications where stable and efficient power supply is critical. These include:

Heatsinks can be made from various materials, each offering distinct advantages. Understanding the properties of these materials can significantly impact thermal management performance:

| Material | Thermal Conductivity | Cost | Durability |

|---|---|---|---|

| Aluminum | High | Moderate | High |

| Copper | Very High | Higher | Very High |

| Steel | Low | Low | Moderate |

While aluminum is lightweight and has good thermal performance, copper's superior thermal conductivity makes it an excellent choice for high-performance applications. However, its increased cost and weight may be a consideration in specific designs. Steel, while more durable and cost-effective, is often not used for heatsinks due to its poorer thermal performance compared to metals like aluminum and copper.

When selecting a 7805 heatsink, several factors need to be taken into account to ensure optimal performance:

Proper installation is crucial for optimal performance. Follow these steps to ensure correct setup:

The 7805 heatsink is a critical component for ensuring the stability and efficiency of electronic circuits. By understanding its functionalities and implementing best practices for installation, users can safeguard their devices against heat-related issues that could otherwise lead to failure or significant loss in operational efficiency. Industry experts underscore the importance of selecting the right materials and ensuring proper design in heatsinks to enhance electronic components' functionality and reliability. Investing in an appropriate thermal management solution not only prolongs device life but also promotes safe operation and optimal performance for a range of challenging applications.

As electronics continue to evolve, pushing the boundaries of performance, future advancements in thermal management will play an essential role in ensuring the reliability and efficiency of devices. One area that shows promise is the development of advanced materials that can improve thermal conductivity while reducing weight and cost. For instance, innovations involving graphene and carbon nanotubes are being explored for their remarkable thermal properties, potentially leading to even more effective heatsinks.

Moreover, the emergence of computer simulations and thermal modeling tools will enable engineers to predict thermal behavior more accurately. This can lead to enhanced designs that account for not just the heatsink but the entire thermal management ecosystem, which includes airflow patterns, the layout of electronic components, and ambient conditions. Designers will be able to optimize the placement of heatsinks for maximum effectiveness, potentially utilizing combined solutions such as active cooling methods alongside passive heatsinks to create a more robust thermal management system.

As energy efficiency becomes more prioritized in electronic design, the relationship between power consumption and thermal management will also emphasize the need for well-integrated solutions. Products such as the 7805 voltage regulator will require even greater attention to cooling strategies as they handle larger power loads in compact spaces.

To further illustrate the practical application of the 7805 heatsink, let's observe case studies from different domains:

A popular gaming console manufacturer faced challenges with overheating in its latest product during high-performance gaming sessions. By integrating a 7805 voltage regulator with a properly sized aluminum heatsink designed to maximize surface area, the development team observed a significant drop in internal temperatures, improving both performance consistency and user satisfaction. Performance metrics indicated less occurrence of thermal throttling, leading to smoother gameplay.

An automotive factory automating assembly lines implemented a robust control system, utilizing multiple 7805 voltage regulators. The heat output from each regulator posed a concern for reliability in an environment with limited airflow. The integration of copper heatsinks with specialized fins allowed for efficient heat dissipation, preventing failures due to overheating. The result was not only an increase in system stability but also a reduction in maintenance downtime, resulting in cost savings and enhanced productivity.

A telecommunications company was upgrading its data center infrastructure, requiring a significant upgrade to its power supply systems. Engineers incorporated 7805 regulators with high-performance heatsinks made of copper for superior thermal management. Their predictive modeling indicated improved heat distribution and airflow optimization, which contributed to minimizing hardware failures and ultimately achieving better energy efficiency across the entire system.

These case studies exemplify the pivotal role that proper thermal management solutions, particularly through the effective use of heatsinks like the 7805, can have on various industries, thereby ensuring ongoing advancements and sustained reliability.

As technology continues to progress, understanding and implementing effective thermal management solutions will become increasingly imperative. The ongoing pressure for miniaturization, efficiency, and high performance means that components like the 7805 voltage regulator—and effectively designed heatsinks—will remain central to successful electronic designs. Future innovations in materials, design techniques, and modeling tools will revolutionize how thermal issues are addressed, setting new standards for performance reliability in consumer electronics, industrial applications, and beyond. By prioritizing effective thermal management today, engineers can pave the way for the next generation of reliable and efficient electronics.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!