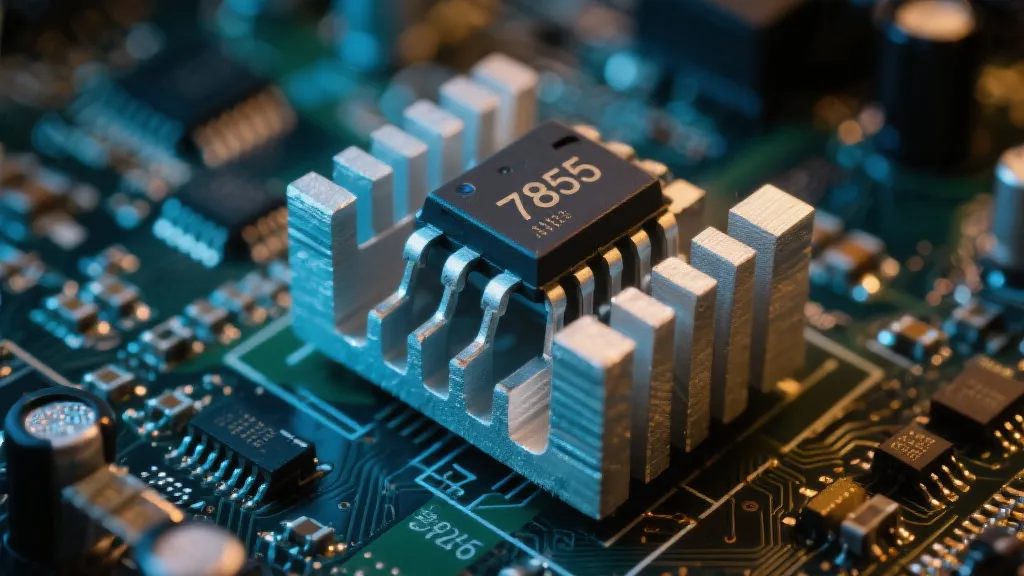

This guide delves into the use and importance of the 7805 heatsink, crucial in thermal management for electronic devices using the 7805 voltage regulator. Heatsinks play a significant role in preventing overheating, ensuring longevity and optimal performance. Understanding the designs and materials that work top, as well as a proper installation methodology, can enhance device reliability.

The 7805 voltage regulator is a staple in the world of electronics, often used for its ability to maintain a steady output voltage of 5V. It serves as a crucial component in various applications ranging from power supplies, battery-operated devices, to microcontroller projects. Despite its versatility and reliability, it can generate a significant amount of heat, especially when the input voltage is considerably higher than the output. This phenomenon occurs due to the voltage drop across the regulator, which leads to power dissipation in the form of heat. The thermal characteristics of the 7805 are critical to its performance, and when the regulator operates beyond its safe thermal limits, it can lead to malfunction or permanent damage. This is where the 7805 heatsink comes into play, providing an effective solution to dissipate excess thermal energy and maintain device efficiency.

Understanding the thermal behavior of the 7805 is essential for anyone working with this component —whether in professional or hobbyist settings. The importance of the heatsink often becomes apparent when the voltage regulator is used without adequate cooling, resulting in voltage fluctuations, performance drops, or complete failure. Proper thermal management, facilitated by a suitable heatsink, not only improves performance but also extends the lifespan of the device by preventing thermal stress and protecting sensitive components.

Heatsinks are designed to absorb and dissipate heat away from electronic components, mitigating the risk of overheating that could lead to component failure or inefficient performance. The basic principle behind a heatsink is to increase the surface area available for heat transfer, allowing heat to dissipate into the surrounding air more effectively. In the case of the 7805 regulator, a well-chosen heatsink can enhance current capacity and improve the longevity of the device. By lowering the operating temperature, the heatsink ensures that the regulator functions within its specified parameters, which is particularly crucial in power electronics where dissipation can be substantial.

The effectiveness of a heatsink is determined by various parameters, including material, size, design, and environmental factors. Materials like aluminum and copper are commonly utilized due to their excellent thermal conductivity, which allows them to transfer heat away from the component efficiently. Additionally, the design of the heatsink plays a pivotal role in its ability to dissipate heat; factors such as the geometry, fin arrangement, and orientation all contribute to the overall thermal performance. Moreover, environmental conditions, such as airflow around the heatsink and the surrounding temperature, can also influence how well heat is dissipated, making the selection process a multi-faceted consideration.

When selecting a heatsink for the 7805 voltage regulator, several considerations come into play:

Proper installation of a 7805 heatsink is critical. Here are some steps to ensure effective attachment and maximum heat dissipation:

| Material | Thermal Conductivity (W/m·K) | Weight | Cost |

|---|---|---|---|

| Aluminum | 205 | Light | Economical |

| Copper | 385 | Heavy | Expensive |

Working with the 7805 and heatsinks can present certain challenges, such as insufficient cooling, space constraints on the board, or the need for more power without a proportional increase in thermal management. Addressing these challenges is important for ensuring consistent performance and reliability, and it often involves a combination of strategies:

As technologies advance, the challenges associated with thermal management in electronic devices become more complex. For professionals seeking to go beyond basic heatsinking strategies, exploring advanced thermal techniques can yield significant benefits:

Active cooling strategies involve the use of external mechanical systems—such as fans or liquid cooling solutions. While the 7805 is often paired with passive heatsinks, combining it with active cooling can drastically reduce thermal buildup, especially in high-current applications. For instance, incorporating a small fan to direct airflow across the heatsink can reduce its thermal resistance significantly, allowing for increased output current capacity or making it feasible to use a smaller heatsink.

Phase Change Materials are substances that absorb and release thermal energy during phase transitions. By integrating PCMs into the design near the 7805 regulator, heat can be absorbed during peak thermal load and released as temperatures drop, smoothing out thermal spikes. This innovative approach allows for the design of compact devices without the bulk of oversized heatsinks.

Beyond standard thermal greases, advanced TIMs can improve thermal conduction between surfaces even further. These materials can be customized for specific applications, providing better performance than traditional thermal paste. Many TIMs have evolved to become softer or more viscous, allowing them to fill gaps more effectively and deliver superior thermal conductivity, particularly important in applications requiring high reliability.

Employing thermal simulation software can help engineers visualize and predict thermal performance before physical implementation. Thermal modeling software can forecast hotspots, analyze thermal flows, and suggest design adjustments that minimize excessive heat generation. By simulating different configurations, engineers can optimize component layout, heatsink performance, and airflow dynamics for the best thermal management possible.

As the demand for compact, efficient electronics increases, thermal management technologies will continue to evolve. Emerging trends suggest a shift towards integration of thermal management solutions directly into PCB designs, leading to more streamlined devices with built-in cooling mechanisms. Techniques such as embedded thermoelectric devices, advanced power packaging technologies, and the integration of sensors for real-time thermal monitoring are gaining traction in modern electronic systems. Furthermore, as energy efficiency remains a key concern in the industry, improvements in voltage regulation technology—such as low dropout (LDO) regulators and switching regulators—are likely to further reduce heat generation in next-generation designs.

In summary, the comprehensive understanding and effective management of thermal needs associated with the 7805 voltage regulator, along with appropriate heatsink selection, are vital for ensuring reliability and performance in electronic projects. As technology continues to advance, ongoing research and development will produce even more innovative solutions to manage heat efficiently and effectively in today's electronics landscape. By keeping abreast of evolving practices and technologies, both professionals and enthusiasts can design and implement systems that leverage the advantages of modern thermal management approaches.

This comprehensive review highlights the pivotal role of 7805 heatsinks in thermal management, providing an essential guide for ensuring electronic component reliability and longevity. By understanding and applying this knowledge, professionals and hobbyists alike can enhance the performance and lifespan of their electronics projects.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!