This article explores the pivotal role of the 7805 heatsink in electronic circuits. A 7805 heatsink aids in thermal management by dissipating heat from the 7805 voltage regulator, which ensures the stable operation and longevity of electronic components. Integrating an effective heatsink into your design can prevent overheating, showcasing why it is vital for maintaining operational integrity.

The application of a 7805 heatsink is crucial in managing heat dissipation in electronic circuits utilizing the 7805 voltage regulator. As electronic devices become increasingly complex, the need for efficient thermal management solutions has never been more paramount, ensuring both performance and durability. The 7805 voltage regulator itself is a staple in electronics, providing a stable 5V output from higher voltage sources. In this context, understanding how to effectively implement a heatsink can significantly influence the performance and longevity of projects ranging from simple circuits to advanced electronic systems.

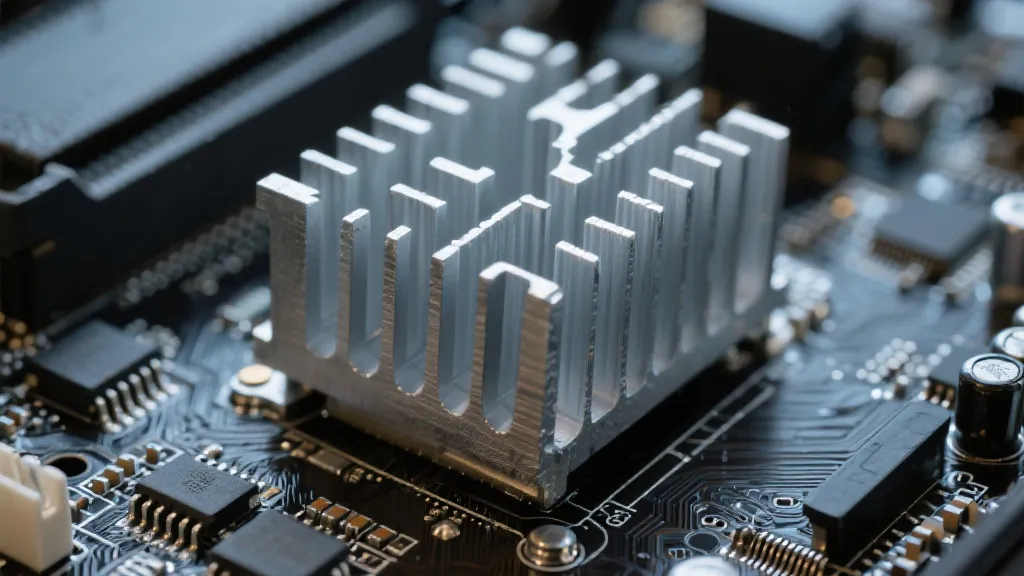

A heatsink serves as the primary thermal management component, tasked with dissipating heat generated by electronic components. Specifically, the 7805 voltage regulator, known for its functionality in converting higher voltages to a stable 5V output, often requires a heatsink to prevent thermal overload. During operation, the 7805 regulator can produce a considerable amount of waste heat; therefore, its placement within a circuit should take into account heat distribution to ensure efficient performance. A heatsink strategically attached to this regulator provides the necessary thermal path that channels this heat away, maintaining the device's temperature within safe operational limits.

Heatsinks come in various shapes and sizes, allowing for customization according to the specific thermal demands of the circuit in which the 7805 is implemented. Coupled with good design practices, a heatsink can optimize the system performance, making it a fundamental part of ensuring the reliability of electronic designs. Moreover, the selection of a compatible heatsink can enhance thermal efficiency, ultimately contributing to the overall effectiveness of an electronic device. The understanding of how a heatsink functions is therefore vital for anyone working with voltage regulators and similar components.

Overheating is a critical concern in electronics that can lead to failure or reduced lifespan of components. The 7805 heatsink plays a vital role in averting this issue, making it indispensable for safely sustaining stable voltage outputs in electronic circuits. The significance of thermal management cannot be overstated; inefficient heat dissipation can lead to temperature rise beyond specified maximum ratings, risking not only the voltage regulator but potentially causing collateral damage to surrounding components.

This is especially important in devices where a stable 5V supply is critical, for example, microcontrollers, sensors, and various digital logic circuits. Some applications may even require that the regulator operates under a specific load current which can exacerbate heating issues. When designing a circuit involving a 7805 voltage regulator, considering the expected thermal performance entails a thorough understanding of the current draw of the components in use and the environmental conditions in which the device will operate.

Furthermore, incorporating a heatsink entails analyzing how thermal properties impact not just the voltage regulator but the entire circuit. A well-designed cooling solution enhances efficiency, allowing the 7805 to function optimally even under maximum load conditions. Best practices dictate the incorporation of heatsinks into designs meant for continuous or high-load operations, particularly in applications operating in high-temperature environments.

When integrating a heatsink into your design, there are several common pitfalls that should be avoided to ensure proper thermal management and overall circuit reliability. Understanding these mistakes can save time and enhance the longevity of devices.

In summary, the 7805 heatsink is an essential component of electronic design for systems employing the 7805 voltage regulator. It not only facilitates thermal management but also preserves circuit integrity by preventing overheating, thereby extending the device’s operative lifespan. Considering the various factors that affect its performance, choosing the right heatsink and ensuring its proper installation can profoundly influence the effectiveness and reliability of your electronic projects. Factors such as material, design, and thermal interface quality should be scrutinized to optimize performance. The art of thermal management in electronics continues to evolve, requiring a deeper understanding of thermal physics, design methodologies, and component interactions.

Moreover, as technology progresses, the advent of more sophisticated cooling techniques and innovations in materials offers exciting opportunities in designing efficient thermal solutions. Frequent advancements in thermal interface materials, such as phase change materials and metal matrix composites, continue to efforts regarding heat dissipation in electronics, potentially revolutionizing the industry. Integrating such advancements with traditional methods can lead to high-efficiency designs capable of withstanding modern operating conditions.

Lastly, as a professional or hobbyist working with voltage regulators and other heat-sensitive components, it is wise to stay informed of new tools, methods, and best practices within the scope of thermal management. Continuous learning and adaptation to emerging technologies will not only elevate the quality of your designs but also enhance the capabilities of the devices you develop, ensuring that they meet the demands of a rapidly evolving electronic landscape.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!