The 7805 heatsink plays a critical role in electronic circuit management, dissipating heat to ensure the stable performance of voltage regulators. These components are fundamental in maintaining the efficiency of 7805 voltage regulators, preventing overheating, and prolonging the longevity of devices. Given their importance, understanding the selection and use of heatsinks is crucial for anyone working in electronics.

The 7805 heatsink is an indispensable component in the realm of electronic circuits, specifically designed to manage thermal dissipation for the 7805 voltage regulator. As a widely used device in electronics, the 7805 voltage regulator provides a constant DC output of 5 volts, which is crucial for many projects and devices, ranging from simple circuits to complex embedded systems. However, like any electrical component, the 7805 can generate heat during operation, impacting performance and potentially leading to failure.

The voltage regulator's primary function is to maintain a steady voltage output regardless of fluctuations in input voltage or load current. This regulation is critical for devices that rely on stable power for proper functionality. While the reliability of the 7805 makes it a popular choice, one must also consider its thermal characteristics. If the regulator operates in an environment where it cannot dissipate heat effectively—either due to high input voltage, increased load current, or insufficient airflow—this can lead to thermal shutdown or irreversible damage. Thus, the inclusion of an adequate heatsink becomes paramount in ensuring the longevity and reliability of the 7805 voltage regulator.

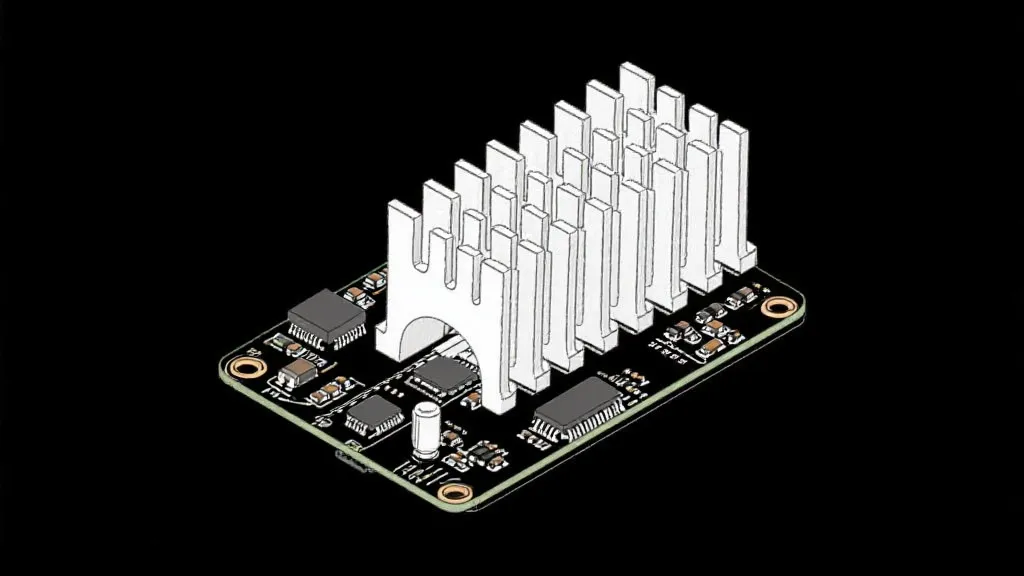

A heatsink is engineered to draw heat away from critical components, dissipating it into the surrounding air. This process ensures the 7805 voltage regulator maintains a stable temperature, thus optimizing functionality and longevity. Heatsinks vary in material, design, and efficiency, aimed to suit different thermal management needs. They are often categorized based on several parameters, including their shape, size, and the specific application within the circuit. A well-designed heatsink increases the surface area available for heat transfer, allowing it to more effectively transform thermal energy into the ambient environment.

For instance, a simple block heatsink may be adequate for low-power applications, whereas high-power circuits may necessitate more sophisticated models incorporating fins or forced-air cooling solutions. The performance of a heatsink is typically measured through its thermal resistance, denoted in degrees Celsius per watt (°C/W). Lower thermal resistance indicates better capacity to dissipate heat, which is especially beneficial for components like the 7805 operating under high loads.

Selecting the appropriate heatsink for your application involves considering factors such as thermal resistance, size, and airflow. A good match ensures effective heat management without causing physical strain on the regulator. Not all applications require extensive heatsinking. When designing circuits with the 7805, factors such as expected load currents, input voltage variations, and ambient temperatures during operation must all be considered. If a voltage regulator is rated for a maximum output current of 1 Amp, the power dissipation in the regulator due to its dropout voltage must also be calculated to determine whether a heatsink is necessary.

Typically, a heatsink with lower thermal resistance offers better heat dissipation, allowing the electrical device to maintain optimal performance. It’s essential to consult the manufacturer’s datasheet for the 7805, which often includes thermal parameters such as the maximum junction temperature and the derating curve corresponding to higher temperatures. As an expert, knowing the thermal specifications of both the heatsink and the regulator is crucial.

One common mistake when selecting a heatsink is ignoring the ambient conditions that the device will operate in. For example, applications in confined spaces with poor ventilation will need a heatsink designed not just for passive cooling but may also require active cooling solutions. It's fundamentally important to ensure the heatsink chosen meets the specific use case requirements to avoid failure or underperformance.

Beyond size and thermal resistance, the material composition of a heatsink plays a vital role. Materials like aluminum and copper are popular due to their excellent thermal conductivity. Aluminum is lightweight and cost-effective, making it suitable for generic applications and less demanding environments. On the other hand, copper provides superior heat dissipation properties and is often employed in high-performance scenarios where heat generation is significant.

Moreover, the design of the heatsink can significantly affect its thermal performance. Many heatsinks are designed with fins or pins that maximize surface area and enhance air circulation. The more surface area exposed to air, the better the heat transfer will be. Some advanced heatsinks utilize a combination of finned structures along with heat pipes, further optimizing heat spread and dissipation.

When considering a heatsink, one should also factor in aesthetic and spatial requirements, as certain designs may be more suitable for compact circuits, whereas others may be designed for larger applications. Furthermore, the thermal interface material (TIM) employed between the heatsink and the regulator should not be overlooked; it can significantly affect the overall thermal performance. Conductive adhesives, thermal pastes, or pads can be utilized to fill microscopic gaps, optimizing the thermal transfer between the two surfaces.

Proper installation of a heatsink is just as important as choosing the right one. Mounting methods can include clips, screws, or thermal adhesive, each offering various stability and efficiency levels. Ensuring good physical contact between the heatsink and the 7805 regulator is imperative for effective heat transfer. Thermal paste is often recommended to fill microscopic inconsistencies, enhancing conductivity.

The installation process should be approached methodically. Start by cleaning both the surface of the heatsink and the voltage regulator; this will promote better adhesion and heat transfer. Then, apply a thin layer of thermal paste—sufficient to cover the surface but not so much as to ooze out when the heatsink is installed. Misapplication can lead to air pockets that impede thermal transfer. Once the TIM is in place, proceed to attach the heatsink securely using the chosen mounting method. Ensuring a tight fit will help maximize the contact area, contributing to better heat dissipation.

It is also important to consider the orientation of the heatsink. In many instances, placing the fins vertically allows for better natural convection, as warmer air rises and cooler air enters to take its place. For environments with forced air, such as in fans or close to other components generating heat, the orientation and layout must be planned to avoid creating heat traps.

| Heatsink Material | Thermal Conductivity (W/mK) | Typical Applications |

|---|---|---|

| Aluminum | 205 | General use, lightweight electronics |

| Copper | 385 | High-performance devices, areas with limited airflow |

| Composite Materials | Varies | Specific heat management scenarios, tailored performance |

| Heat Pipes | N/A | Advanced cooling solutions, high-performance systems |

In today's ever-evolving tech landscape, efficient thermal management remains a priority. As electronic devices continue to shrink and component density increases, effective heat dissipation becomes even more critical. Manufacturers and designers are continually seeking innovative ways to optimize thermal performance through advanced materials and designs. For instance, some modern heatsinks incorporate designs that allow for enhanced airflow or employ phase-change materials that actively manage heat transfers more efficiently than traditional methods.

Understanding and implementing quality heatsink solutions for your 7805 voltage regulators can result in not just performance optimization but also enhanced device reliability. As devices become more integrated, engineers must balance miniaturization with effective cooling solutions, leading to a growing demand for customized thermal management systems in sectors like automotive electronics, mobile devices, and computer hardware.

Overall, investing in a quality 7805 heatsink is an investment in the reliability and efficiency of your electronic applications. Whether you are tinkering with hobby electronics or developing sophisticated tech, the role of effective thermal management cannot be overstated. This essential component ultimately ensures that your projects not only function effectively but maintain consistent operational standards over extended periods.

Finally, continual developments in thermal simulation tools have enabled engineers to better predict and analyze heating factors in designs before physical implementation. This helps prevent overheating issues from arising by allowing for more accurate designs tailored to specific operating conditions, providing an added layer of reliability. As new technologies emerge, including innovative materials and application techniques, the realm of heatsinking is bound to witness exciting advancements, ensuring continued progress in the field of electronics.

In summary, the journey of selecting and implementing a 7805 heatsink doesn’t end with just putting a piece of metal on a regulator. It encompasses a vast array of considerations from materials to design and application. Through careful attention to these details, one can achieve not only a working electronic circuit but a reliable and robust system that stands the test of time.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!