Discover the importance and application of 7805 heatsinks, crucial components designed to manage thermal output in electronic circuits. The article discusses their functionalities, the importance of thermal management in electronics, and provides insights into choosing the right heatsink for optimal performance.

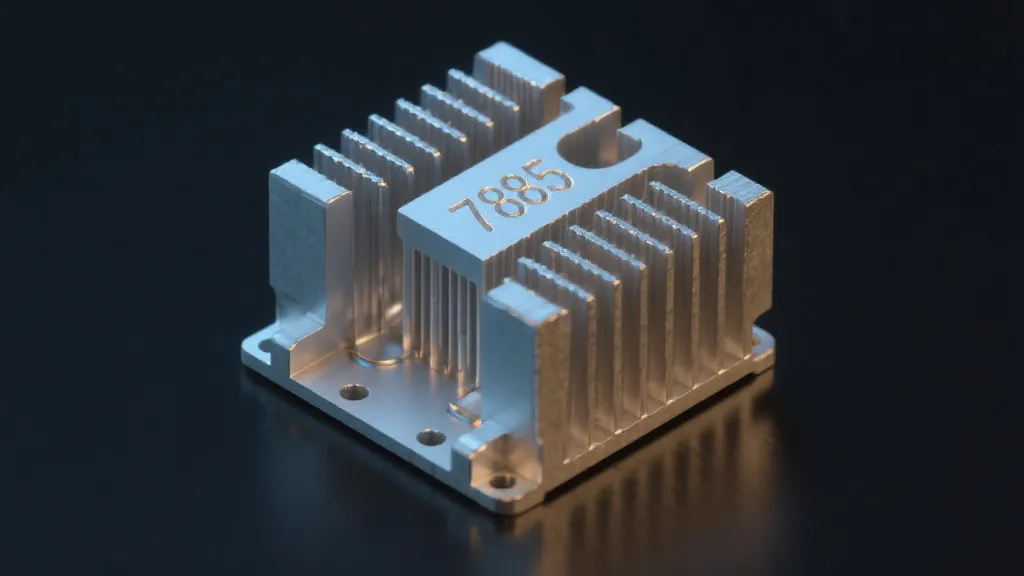

The 7805 heatsink is an essential component in the field of electronics, particularly for applications requiring regulated voltage. These devices are crucial for managing heat dissipation when using the 7805 voltage regulator circuit. The 7805 voltage regulator is known for providing a stable output voltage of 5 volts, which is widely used in various electronic projects, from simple hobby circuits to complex industrial applications. However, with great power comes great responsibility, especially concerning heat management. This article delves into their necessity, functionality, and how to effectively utilize them in electronic systems.

Managing heat in electronic components is vital to ensure system stability and longevity. The 7805 heatsink aids in dissipating the excess heat generated by voltage regulators, preventing damage and maintaining operational efficiency. Uncontrolled heat can degrade semiconductor materials, leading to catastrophic failure. Overheating can result not only from excessive current draw by connected loads but also from inadequate heatsinking solutions in hot environments. Therefore, an understanding of thermal management best practices becomes pivotal to ensure reliable performance.

In many cases, if a voltage regulator operates beyond its specified temperature range, it may automatically shut down to protect itself, leading to unplanned interruptions in operation. This self-protection feature, while useful, is not an ideal solution, especially in critical applications where continuous operation is necessary. A well-designed heat dissipation solution with a 7805 heatsink ensures that the components operate within safe thermal limits, significantly prolonging their lifespan, enhancing reliability, and maintaining consistent performance over time.

Selecting an appropriate heatsink depends on several factors including the regulator's operating conditions, size constraints, and the ambient temperature of the environment. The effectiveness of the heatsink is measured in thermal resistance, represented as degrees Celsius per watt (°C/W). A lower thermal resistance indicates better heat dissipation capacity.

Some factors to consider when selecting a heatsink include:

| Criterion | Parameters |

|---|---|

| Size | Dependent on the space available within the device design. |

| Material | Typically made from aluminum or copper due to their thermal properties. |

| Thermal Resistance | Should match the system requirements to ensure optimal heat management. |

| Mounting Options | Examine the mounting configuration suitable to the project, including using screws, clips, or thermal adhesive. |

| Cost | Consider budgeting constraints without compromising quality and efficiency. |

Proper installation of the 7805 heatsink is crucial. Ensuring firm attachment and using an appropriate thermal interface material can enhance heat dissipation. The right thermal interface material, such as thermal grease or pads, can significantly improve thermal transfer from the regulator to the heatsink. The method of applying thermal interface materials must also be meticulously executed to avoid air pockets that can hinder heat flow.

Orientation and airflow around the heatsink further influence its performance. For natural convection, it's beneficial to mount the heatsink vertically, as this allows cool air to enter from the bottom and warm air to escape from the top. If space allows, placing a fan nearby can enhance airflow, especially in configurations where the device generates higher heat levels or operates in warmer environments.

Additionally, ensuring that the heatsink's fins or surface area is unobstructed and exposed to the ambient air is crucial. Dust, grime, or any object blocking airflow can severely compromise the heatsink’s efficiency. Regular maintenance and cleaning can contribute to prolonged functionality and optimal thermal dissipation.

When working with heatsinks, several common mistakes can be detrimental to performance. Awareness of these pitfalls can lead to more effective implementation:

The 7805 regulator may generate excessive heat under load, and a heatsink prevents overheating, ensuring reliable operation. Without proper cooling, the regulator could exceed its maximum temperature threshold, leading to decreased performance or permanent damage.

Overheating can cause the voltage regulator to fail, potentially damaging other components in the circuit. The thermal shutdown feature of the 7805 can provide temporary relief but cannot replace a proper heatsink solution.

Not all heatsinks are suitable; selection depends on thermal resistance requirements and physical space constraints. Using a heatsink meant for different applications or configurations can lead to inefficient cooling.

Monitoring the temperature of the regulator during operation can provide insights into whether the heatsink is adequate. If the regulator exceeds safe operating temperatures under load, a more effective heatsink or improved cooling methods should be considered.

Yes, combining a heatsink with a fan can significantly enhance cooling performance, particularly in setups with high power dissipation. This combination is commonly referred to as active cooling and is widely used in high-performance applications.

According to industry experts, as electronic components become more compact yet increasingly powerful, the role of efficient heat dissipation is paramount in design considerations. Heatsinks like the 7805 are indispensable in managing the thermal loads effectively, especially in complex systems. The trend of miniaturization in electronics amplifies the importance of heat management, necessitating innovative thermal solutions that comply with stringent space and performance requirements.

Experts emphasize that thermal management should be integrated early in the design phase. Proactive engagement with thermal modeling software or conducting thermal simulations can provide valuable insights into temperature profiles and help identify potential overheating issues before they arise in physical prototypes. Manufacturers and designers are increasingly looking toward advanced materials that provide enhanced thermal conductivity while maintaining a lightweight structure in their designs.

The advancement of technology has spurred innovations in heat management solutions, ranging from high-performance heat sinks to the integration of new materials. Research into phase change materials (PCMs) offers a promising pathway since these materials can absorb and release large amounts of heat during phase transitions, maintaining stable temperature profiles within complex electronic systems.

Furthermore, the development of heat pipes and vapor chambers has elevated thermal management capabilities significantly. These technologies utilize phase change principles and can spread heat over larger areas, facilitating better thermal performance in compact designs. As a result, these cutting-edge methods are becoming increasingly popular in high-density applications where traditional heatsink designs may fall short.

Thermal interface materials are also evolving, with new compounds designed to lower thermal resistance even further, thereby improving the efficiency of heat transfer between the electronic component and the heatsink. Some newer products feature advanced adhesive properties, ensuring that the heatsink maintains a secure bond even under varying temperature conditions, further improving reliability.

The 7805 heatsink serves as a vital part of electronic designs, crucial for maintaining thermal equilibrium and ensuring the longevity of both the voltage regulator and the overall circuit. A thorough understanding of thermal management principles helps in selecting the right heatsink to optimize performance. By considering factors like thermal resistance, ambient temperature, and installation techniques, designers can create robust systems that perform reliably over time.

The integration of advanced materials and technology in heatsink production continues to drive the efficiency of thermal management solutions, making them more critical in the ever-evolving field of electronics. As we move toward more intricate and high-performance electronic devices, the need for effective thermal management solutions, including the humble yet significant 7805 heatsink, will undoubtedly remain paramount. Embracing best practices in thermal management and keeping abreast of emerging technologies will ensure that future designs meet both performance and reliability thresholds.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!