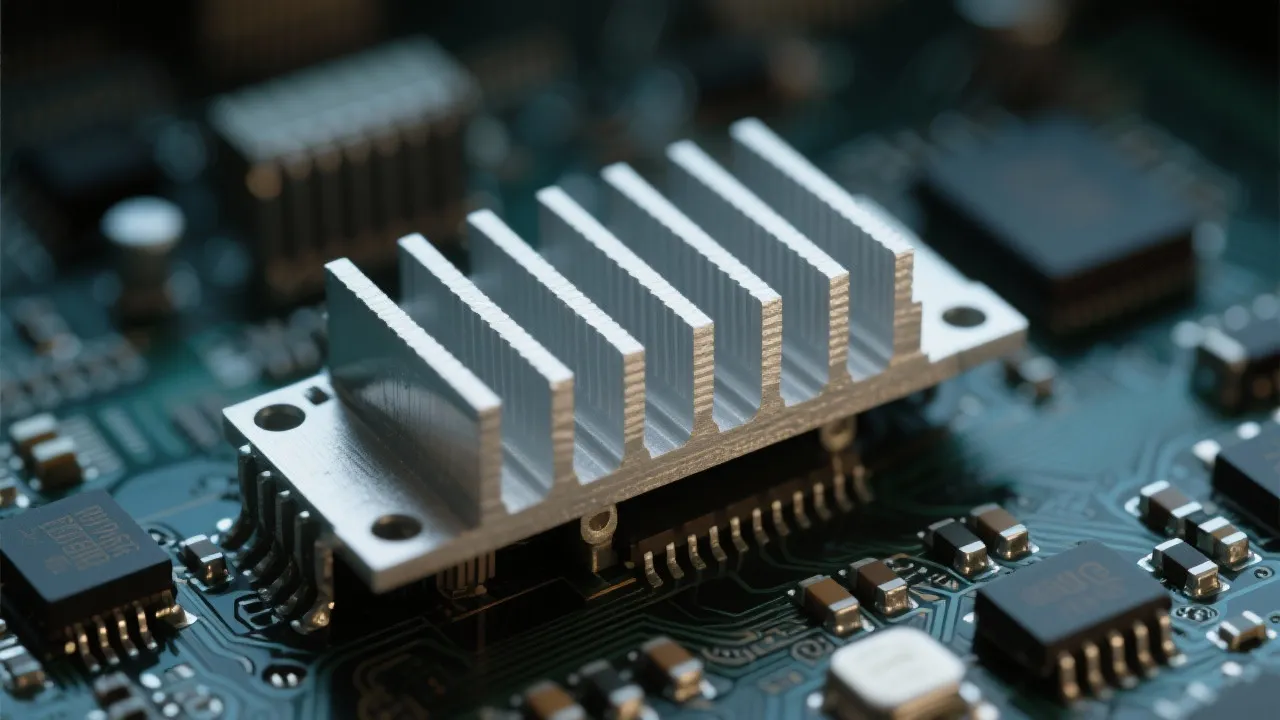

The LM380 Heatsink is critical in enhancing the performance of the LM380 audio amplifier by efficiently dissipating heat. This guide delves into the significance of heatsinks in electronic applications, focusing on their role in audio enhancing technologies. Learn about the benefits, installation, and common FAQs regarding incorporating a heatsink into an LM380 setup.

As technology evolves, the demand for robust electronic components such as the LM380, a power amplifier integrated circuit, has heightened. Crucial to its optimal functioning is the LM380 Heatsink, which ensures effective thermal management. Let us explore the essence of heatsinks, particularly in conjunction with the LM380, and their role in modern electronics.

The primary function of a heatsink is to dissipate the excess heat generated by electronic components during operation. In the context of the LM380 audio amplifier, a heatsink becomes indispensable. It prevents thermal overload, thereby enhancing longevity and performance by maintaining safer operating temperatures. A thorough understanding of this heat management is essential in designing systems for professional audio applications, hobbyist projects, and industrial electronics.

Selecting the appropriate heatsink is crucial for maximizing the LM380’s efficiency. Factors to consider include material, size, and installation compatibility. Generally, heatsinks are made from aluminum or copper due to their excellent thermal conductivity. It is also essential to choose a heatsink that matches the intended use case, whether it be for simple audio applications or high-power devices used in professional sound systems.

| Material | Thermal Conductivity | Cost Efficiency |

|---|---|---|

| Aluminum | Good | High |

| Copper | Excellent | Moderate |

| Metal Matrix Composites | Very Good | Higher Cost |

| Thermal Grease-filled Heatsinks | Good | High |

Additionally, ensuring the heatsink is the right size for your specific LM380 application is vital, considering both the physical space available and the amount of heat produced during operation. The surface area of the heatsink plays a significant role in its ability to dissipate heat; larger heatsinks can generally dissipate more heat due to increased surface area.

Proper installation of the heatsink is as important as selecting the right one. An improper installation can negate the benefits of a quality heatsink. Here are detailed steps to effectively install your LM380 heatsink:

After installation, maintaining the heatsink is crucial. Dust accumulation can hinder its ability to dissipate heat effectively, so regular inspection is necessary.

Q: Why does the LM380 require a heatsink?

A: The LM380 produces heat during operation, and a heatsink helps dissipate this heat, protecting the device from overheating and potential damage. In audio applications, keeping the amplifier cool is essential to prevent distortion and maintain sound quality.

Q: Can I use any heatsink with the LM380?

A: It is crucial to select a heatsink compatible in size and thermal capacity with the LM380 to ensure proper cooling. Using an inadequate heatsink can result in overheating and reduced performance.

Q: Is using thermal paste necessary?

A: Yes, applying thermal paste improves the efficiency of heat transfer between the LM380 and the heatsink. The paste fills microscopic gaps between surfaces, enhancing thermal conductivity.

Reputable manufacturers that supply quality LM380 heatsinks emphasize customization options to meet specific system designs in audio applications. Their products often incorporate advanced thermal materials and enhanced designs for optimal heat dissipation. Ongoing innovations focus on enhancing material efficiency and heat dissipation techniques. Manufacturers aim to provide solutions that streamline audio amplifier performance, indicating a trend towards highly versatile and efficient electronic cooling solutions. The advent of nanotechnology has also influenced the design of thermal materials, leading to more effective and compact heatsink designs.

In recent years, there have been notable advances in heatsink technology that cater to the evolving needs of high-performance audio applications and compact electronic devices. These advancements include:

In addition to heatsinks, engineers often have to choose between passive and active cooling systems. Each approach has its pros and cons, often dictated by the application’s power and thermal requirements.

The integration of a LM380 Heatsink is essential for any setup utilizing the LM380 audio amplifier, ensuring not only operational efficiency but also component safety. For successful usage, select appropriately sized and material-suave heatsinks, implement effective installation procedures, and address common inquiries to further harness your audio amplifier’s full potential. As noted by experts in the field, ensuring optimal heat management strategies across electronics remains pivotal for proactive sustainment and technological advancement.

Moreover, understanding the ever-evolving landscape of thermal management, including advancements in materials and innovative cooling solutions, will serve designers and engineers well in optimizing their projects. As consumer demands for better performing, reliable, and compact audio devices continue to grow, the focus on thermal management will remain at the forefront of electronic design considerations. Ensuring that you have a deep understanding of heatsink requirements for the LM380 will not only protect your investment but will also significantly enhance the overall performance of your audio systems.

The LM380 audio amplifier is widely utilized in various applications, ranging from consumer electronics to professional audio equipment. Each application reflects the significance of effective thermal management through quality heatsink design:

Looking forward, the future of LM380 heatsinks appears promising, with a focus on enhancing performance, efficiency, and sustainability. Innovation in materials science and manufacturing processes is directing attention towards lightweight and recyclable heatsink options that not only perform better but also minimize environmental impact.

Moreover, as the electronics industry moves towards smaller and more powerful components, thermal management solutions will need to become even more sophisticated. Heatsinks will likely need to integrate seamlessly with other system components, with advancements in micro-channel designs and integrated cooling systems that allow for better heat distribution in compact designs.

In conclusion, the importance of heatsinks in conjunction with the LM380 cannot be overstated. By understanding the nuances of selecting and installing heatsinks effectively and keeping abreast of technological advancements, you can help ensure that your audio systems perform optimally for years to come.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!