The LM380 heatsink plays an indispensable role in thermal management for electronic devices leveraging LM380 audio power amplifiers. These heatsinks ensure efficient heat dissipation, maintaining the longevity and performance of electronic components. Knowledge of heatsink materials, design, and specifications is crucial for optimizing cooling solutions in various applications.

The LM380 heatsink is pivotal in ensuring the thermal stability of audio power amplifiers using LM380 integrated circuits. An LM380 amplifies audio signals, and in this intense process, it generates significant amounts of heat which must be managed to maintain optimal performance and reliability. The heatsink is designed to absorb and dissipate this heat efficiently, preventing the components from overheating. Adequate thermal management is essential because excessive heat can affect not only the LM380 itself but also surrounding components. If the temperatures rise beyond a certain threshold, the performance can degrade rapidly, leading to possible distortion in audio output or intermittent signal failures that can be both frustrating for the user and harmful to the longevity of the device.

In scenarios where continuous audio playback or high power demands are expected, the heatsink's role becomes even more critical. Efficient heat dissipation can mean the difference between a device that performs consistently and one that fails due to thermal overload. Therefore, a carefully designed heatsink is indispensable for maintaining a consistent audio experience, especially in high-performance audio systems.

Heat dissipation is essential because excessive heat can degrade the electronic components, risking malfunction or good damage. In the context of the LM380 chip, overheating can affect signaling quality and shorten the component's life. Ensuring that the LM380 keeps its temperature within operational limits is essential to avoid thermal runaway, a condition where increased heat generation leads to further temperature rise. This vicious cycle can quickly lead to catastrophic failures.

Moreover, heat impacts the fidelity of audio performance. In audio amplifiers, even minor fluctuations in temperature can introduce noise or distortions in the output signal. With high thermal efficiency provided by a well-designed heatsink, you can maintain both the quality and reliability of audio output. Therefore, a well-designed LM380 heatsink is not just beneficial but necessary to extend the lifespan of the device. The careful consideration of heat dissipation ensures that audio systems provide a pleasant experience for users without interruptions or quality loss due to thermal issues.

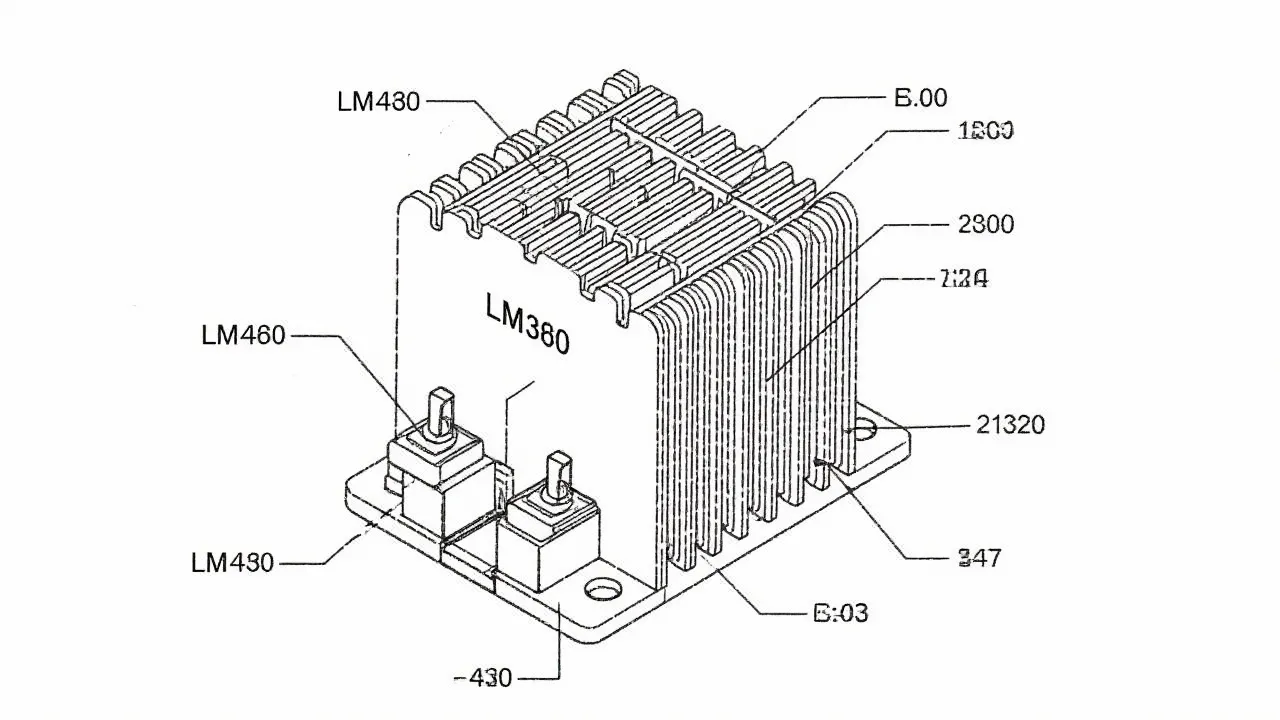

The effectiveness of a heatsink is determined by material choice, surface area, and architecture. Materials like aluminum and copper are preferred due to their excellent thermal conductivity. The design often incorporates fins or pins, which expand the surface area and allow for better air circulation, enhancing the heat transfer process. Fins, for instance, create a larger surface area for heat dispersion into the surrounding air, and by careful arrangement, they can significantly boost the airflow around the heatsink by creating turbulence that improves heat transfer via convection.

Another important aspect of the heatsink design is its physical dimensions and shape. A square or rectangular profile can accommodate standard mounting practices, while specialized shapes may be employed in compact or confined spaces. The overall height and arrangement of the fins also have a major impact on the heatsink's performance, and different designs may be employed based on the expected thermal load and enclosure space.

Aluminum is a popular choice due to its lightweight and relatively high thermal conductivity, making it easy to handle and install. It's also cost-effective for large-scale production, making it the standard for many consumer electronics. Copper, while heavier and costlier, offers better thermal performance. It can efficiently draw heat away from the LM380, which is why it's sometimes used for high-end applications where thermal performance is paramount.

Some applications might involve anodized heatsinks, which are treated to improve corrosion resistance and heat emission. Anodizing not only enhances the aesthetic appeal but also improves the thermal oxide layer on the metal, further improving its ability to dissipate heat. This protective oxide layer prevents oxidation while allowing for high heat output efficiency. The choice of materials can significantly impact the overall thermal performance and longevity of the heatsink in various environments, especially in humid or corrosive conditions.

Performance can be optimized by ensuring good thermal contact between the heatsink and LM380. Thermal paste or pads can be used to minimize air gaps. The type of thermal interface material (TIM) chosen can greatly influence the effectiveness of heat transfer. Liquid thermal pastes are often favored for their excellent conductivity and flexibility, effectively filling any microscopic gaps between the heatsink and the chips they touch.

Additionally, considering the airflow within the device enclosure—whether natural or forced—is essential to achieving the desired cooling efficiency. Forced convection systems with fans can significantly improve performance by actively moving air over the heatsink and extending the effective cooling duration. Conversely, systems relying on passive cooling need to have strategically placed vents to ensure adequate airflow. The direction of airflow, importance of unobstructed paths, and even the placement of any nearby components must be carefully planned to achieve optimal heat management.

It’s also vital to monitor temperatures in real-world applications. Implementing temperature sensors can provide feedback on the effectiveness of heatsink designs under load. This data can help in making informed decisions on improvements or modifications necessary for ongoing projects.

Current trends show a shift towards more compact and efficient heatsink designs, driven by the demand for smaller, more powerful consumer electronics. Innovations in manufacturing processes have enabled the production of high-density heatsinks that provide superior performance in increasingly constrained spaces. Advances in materials, such as the use of composite materials and graphene, are also under exploration to enhance thermal performance and lightweight characteristics.

Graphene, in particular, represents a promising frontier in heat transfer technology due to its remarkable conductivity properties. Some manufacturers are experimenting with graphene-infused polymers to produce hybrid heatsinks that could potentially merge the light weight of plastic with the thermal efficiency of metals. The objective for designers today is not only to ensure effective cooling but also to do it in a way that supports the environmental goals of reducing the ecological impact of electronic waste.

This competitive landscape also includes a growing emphasis on integrating heatsinks into device designs from the ground up rather than as afterthoughts. Efficient simulation tools now allow for thermal modeling early in the design process, which can save both time and resources by optimizing the heatsink alongside other internal components, leading to improved performance and reliability.

| Material | Thermal Conductivity | Cost | Features |

|---|---|---|---|

| Aluminum | 205 W/mK | Moderate | Lightweight, Good corrosion resistance |

| Copper | 385 W/mK | High | Excellent thermal performance, Heavier |

| Anodized Aluminum | 180-210 W/mK | Moderate to High | Improved corrosion resistance, Better heat dissipation |

| Graphene Composite | 1000 W/mK (theoretical) | High | Exceptional thermal performance, Potential for lightweight designs |

Q: How do I know if my LM380 heatsink is effective?

A: An effective heatsink will maintain the amplifier's temperature within the recommended range during operation. IR thermometers or thermal imaging can help in assessing performance. Additionally, monitoring performance over time will give insight into whether heat is being managed adequately, particularly under maximum load situations.

Q: Can I upgrade to a larger heatsink if overheating issues persist?

A: Yes, increasing the heatsink's size, or switching to a more conductive material, can enhance heat dissipation if space and compatibility allow. It's important to ensure that any modifications do not interfere with airflow or other components within the device. It may also be beneficial to review the installation to ensure the thermal interface material is applied correctly to maximize performance.

Q: What can I do if my heatsink is still not functioning properly?

A: If overheating persists even after optimizing heatsink size and materials, evaluating the overall system design may be necessary. Look for airflow obstructions, consider implementing forced convection through fans, or assessing the PCB layout to ensure ideal contact with the heatsink is achieved. You might also consider the operating environment – high ambient temperatures can adversely affect overall system performance.

The LM380 heatsink is a critical component in maintaining the function and reliability of audio amplifying circuits. Proper selection and installation ensure the longevity of the device and optimal performance. A well-designed heatsink can significantly impact the overall system performance, ensuring that audio integrity is maintained without distortion or failure due to thermal issues. As technology advances, exploring newer materials and designs will be vital to keeping up with thermal challenges in electronics. The ongoing innovations in heatsink technology are facilitating the production of high-performance devices in smaller footprints, making audio technology not only more reliable but also more accessible. Future trends will likely continue to move towards eco-friendly materials and sustainable manufacturing processes, providing an exciting avenue for further research and development in thermal management.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!