This comprehensive guide explores the role and importance of the LM380 heatsink in electronic circuits, emphasizing its heat dissipation functionality. The LM380 power amplifier is a crucial component in electronics, requiring efficient thermal management for optimal performance. The importance of selecting the right heatsink design and material is also discussed in detail.

In the domain of electronics, thermal management is a critical aspect that dictates the performance and longevity of components. Among these components, the LM380 power amplifier stands out due to its widespread application in audio circuits. The proper management of heat produced during its operation is crucial for achieving the desired audio fidelity and overall reliability of the device. To optimize its functionality, an efficient heat dissipation system, like the LM380 heatsink, is indispensable. This article delves into the intricacies of the LM380 heatsink, examining its design principles, applications, selection criteria, and trends in heatsink technology, along with implications for future electronic design.

Electrical components generate heat during operation, and excessive temperatures can lead to degradation or failure. The LM380 amplifier, known for its reliability and audio fidelity, operates at a power level that requires effective thermal management to maintain its performance standards. A heatsink serves this purpose by acting as a heat exchanger, dissipating the heat generated to prevent overheating and maintain optimal operating conditions. This is particularly important in high-power applications where heat can accumulate rapidly if not managed properly.

Incorporating a heatsink in the design of electronic circuits, including those utilizing the LM380 amplifier, not only enhances the safety and reliability of the devices but also extends their operational lifespan. The performance of audio amplifiers is especially sensitive to temperature fluctuations; thus, engineers devise meticulous designs to ensure consistent audio quality and device longevity.

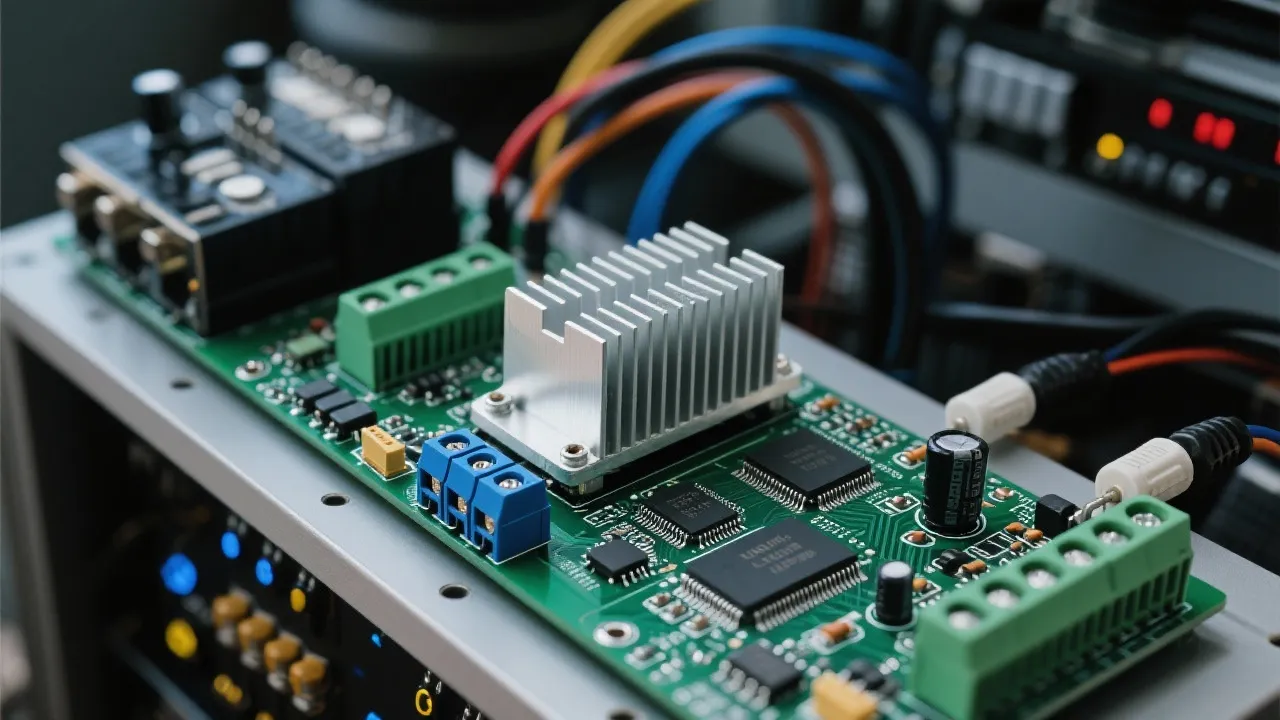

The design of a heatsink is pivotal to its effectiveness. Factors such as material, surface area, and airflow impact the heatsink's ability to transfer heat away from the device. Typically constructed from materials with high thermal conductivity, such as aluminum or copper, these heatsinks are designed with fins to maximize surface area and improve efficiency. The compatibility between the LM380 and its heatsink is determined by the amplifier's power dissipation rating, the ambient operating conditions, and the intended application of the amplifier.

For the LM380 to function optimally in audio circuits, proper integration of the heatsink is key. This involves meticulous attention to the mounting process, ensuring firm contact with the amplifier for efficient thermal conduction. To achieve this, thermal paste is often used to bridge the gap between surfaces, reducing thermal resistance and improving heat transfer. The thermal interface material plays a crucial role in optimizing the thermal conductivity between the LM380 and the heatsink.

Choosing the right heatsink for the LM380 requires careful consideration of several criteria:

| Criteria | Details |

|---|---|

| Thermal Resistance | The temperature differential per unit of power dissipated; critical for assessing heatsink efficiency. Typically expressed in °C/W (degrees Celsius per watt), lower values indicate better thermal performance. |

| Ambient Temperature | Expected environmental conditions that influence the thermal performance of the heatsink, which in turn affects overall system reliability. Understanding the thermal environment is critical for effective design. |

| Physical Dimensions | Constraints based on the size of your electronic setup and space available. The chosen heatsink must fit within the physical boundaries imposed by the circuit board and enclosure. |

| Mounting Type | Different mounting configurations may require specific heatsink designs that accommodate their respective thermal interfaces. |

| Cost | Considering budget constraints while evaluating the performance of potential heatsinks is essential, as it impacts the overall project cost. |

| Application Conditions | Whether the application involves continuous or intermittent duty cycles greatly affects the thermal management requirements. |

Commonly employed in audio applications, the LM380 amplifier is valued for its straightforward operation, sound quality, and ease of use within various circuits. It finds its place in both consumer electronics, such as home audio systems, as well as in more demanding professional audio equipment settings. Incorporating a heatsink extends its usability to more demanding environments and higher power applications, ensuring reliability across diverse scenarios. In professional audio equipment, achieving clarity and eliminating distortion are paramount; thus, integrating an efficient heatsink becomes a pivotal design choice.

Moreover, the LM380 amplifier is also utilized in automotive applications, where the conditions can be extreme. The heat dissipation characteristics of the heatsink become critical in such environments, as amplifiers in vehicles often deal with both high ambient temperatures and varying power demands due to music playback and other electronic systems. Heatsinks designed for automotive uses must withstand vibration and provide consistent thermal performance despite the lack of a controlled climate.

In architectural acoustics, where high accuracy in sound systems is essential, the reliable performance of the LM380 with proper thermal management ensures that audio systems maintain their audio fidelity. Designers often collaborate closely with acousticians to optimize the placement of the heatsinks in conjunction with the acoustic design of the spaces to maximize sound quality.

As electronic devices become more compact yet powerful, the demand for advanced heatsink technologies intensifies. Innovations like those in materials science, including graphene and phase-change materials, are paving the way for next-generation thermal management solutions. The use of advanced nanotechnology methods can significantly enhance the thermal conductivity of traditional materials, providing exceptional heat dissipation properties. In the future, these advancements could redefine standards for efficiency and cooling capabilities in electronic systems.

Furthermore, the trend towards miniaturization in electronics indicates a growing need for more efficient design methodologies that combine thermal and electrical characteristics. For instance, thermoelectric devices could be integrated alongside conventional heatsinks, enabling active cooling alongside passive heat dissipation. This integration would allow for more sophisticated thermal management systems that can adapt to varying loads and heat generation rates dynamically.

Another exciting direction involves the utilization of computational modeling to optimize heatsink performance before physical prototypes are produced. Engineering simulations can help predict thermal behavior and identify potential design improvements, reducing the time and cost associated with experimental approaches.

In conclusion, effective thermal management via the selection of the appropriate heatsink is critical for optimizing the performance of the LM380 amplifier within various electronic circuits. Understanding the principles underlying heatsink design, material selection, and proper integration can lead to improved durability, reliability, and audio quality. As technology advances, embracing new materials and methodologies will continue to evolve the fundamental aspects of thermal management in electronics. The trends towards innovation and miniaturization indicate that the intersection of thermal and electronic design will yield uncharted territories, enhancing systems across the audio landscape.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!