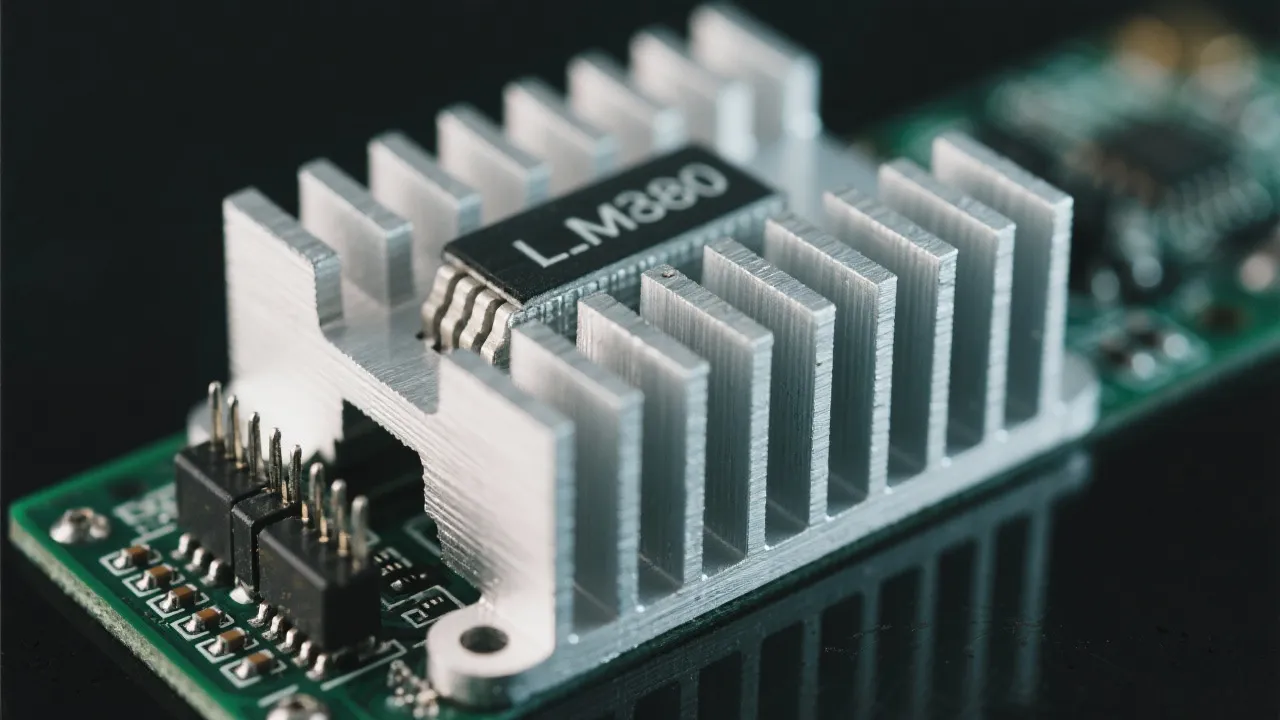

Lm380 heatsinks are essential components in electronic circuits to manage temperature and ensure the reliability of amplifiers. Known for dissipating heat effectively, these heatsinks prevent overheating and extend the lifespan of electronic devices. In this article, we delve into the intricacies of Lm380 heatsinks, their importance in electronics, and explore some frequently asked questions from industry experts.

In the world of electronics, maintaining optimal temperatures is crucial for the performance and longevity of components. Lm380 heatsinks play a pivotal role in this aspect, ensuring that devices operate efficiently by dissipating excess heat. Primarily used with amplifiers like the Lm380, these heatsinks help manage thermal performance, preventing system failures due to overheating. The integration of heatsinks not only elevates the reliability of the devices but can also enhance audio quality in sound systems, making them an essential part of modern electronic design.

The Lm380 is a power amplifier widely utilized in audio systems and signal processing. Without a heatsink, the Lm380 can experience overheating, which not only reduces its efficacy but also risks damage to the entire circuit. Overheating might lead to distortion in audio output, signal loss, or even complete amplifier shutdown. By incorporating a heatsink, the device maintains a stable temperature, thereby ensuring reliability and enhancing performance. This is particularly critical in climates where atmospheric temperature can fluctuate significantly. Engineers and hobbyists often overlook the importance of adequate thermal management, which can lead to costly repairs or replacements.

A heatsink is designed to increase the surface area that comes into contact with cool air, thereby enhancing heat dissipation. Generally made from materials with high thermal conductivity like aluminum or copper, heatsinks absorb and transfer heat away from sensitive components. The cooling process involves several physical phenomena: conduction, where heat flows through the heatsink material; convection, where air movement facilitates heat removal; and radiation, where heat is emitted from the heatsink into its surroundings. These processes work together to ensure that the Lm380 amplifier operates within safe temperature limits, allowing for optimal performance without risking damage to its internal circuits.

Selecting an appropriate Lm380 heatsink is crucial for optimal performance. Factors to consider include the heatsink's thermal resistance, size, material, and compatibility with the Lm380 design. Thermal resistance, measured in degrees Celsius per watt (°C/W), gives a clear indication of how well a heatsink can dissipate heat. A lower thermal resistance value means better heat transfer. For effective performance, a heatsink must not only fit the physical dimensions of the amplifier but also meet the thermal regulatory requirements of the specific application. Consideration of airflow around the heatsink and other components is also critical, as it influences the ability to cool effectively.

| Material | Thermal Conductivity | Advantages | Disadvantages |

|---|---|---|---|

| Aluminum | 235 W/mK | Lightweight, cost-effective, and robust. Ideal for most applications where weight and cost are factors. | Lower thermal conductivity compared to copper, and can be less durable over extended use under high temperatures. |

| Copper | 400 W/mK | Superior thermal conductivity, making it highly effective for high-performance applications. | Heavier and typically more expensive, which may not be suitable for all platform designs. |

| Graphite | 200-300 W/mK | Successively lighter than metals and can be formed into various shapes. Good for unique design constraints. | Less widely used and can be more costly; handling properties might not be as straightforward. |

Reliability in electronic components is often a reflection of the manufacturer. Some of the leading suppliers of Lm380 heatsinks include Aavid, Wakefield, and Advanced Thermal Solutions. These companies offer a range of heatsinks distinguished by their efficiency, build quality, and compatibility with various electronic components. Besides these top manufacturers, there are also smaller firms and upstart manufacturers that specialize in custom solutions, which can be beneficial for unique design specifications where standard options may not suffice.

For instance, Aavid Thermalloy is known for its extensive portfolio of effective heatsink solutions, providing a wide range of options tailored for various applications. Wakefield Engineering is another reputable name, renowned for producing innovative thermal management products. Advanced Thermal Solutions often specializes in high-performance heatsinks and cooling technologies geared towards maximizing efficiency and reliability.

Beyond the mere selection and installation of heatsinks, environmental factors play a significant role in their overall effectiveness. Ambient temperature, humidity, and airflow can impact the efficiency of heat dissipation dramatically. For example, in a well-ventilated room with a steady flow of air, a heatsink can perform optimally. However, in confined spaces or high-humidity environments, the ability to dissipate heat can be significantly hindered, leading to potential thermal failures.

Designing an electronic system that includes an Lm380 amplifier requires thorough consideration of other factors such as airflow paths. Creating dedicated airflow channels with fan-assisted cooling or utilizing convection-enhancing designs can greatly improve performance. Moreover, using software simulations to model thermal performance in specific environments can provide insights that lead to more efficient thermal management solutions.

The technology surrounding heatsinks has evolved significantly over the years, with a variety of innovations emerging to improve thermal management. Recent trends include integration with active cooling systems, increased utilization of heat pipes for superior thermal management, and the advent of phase change materials which can absorb heat in very efficient ways when combined with traditional heatsink materials.

Active cooling systems involve using fans or other cooling devices in conjunction with heatsinks to enhance airflow and heat dissipation capabilities. This combination can extend the life of electronic components significantly, especially in high-performance settings such as audio amplification, gaming, and computing applications. Meanwhile, heat pipes—which use phase change between liquid and vapor in a sealed tube to transfer large amounts of heat—have become popular due to their efficiency.

The exploration of nanotechnology in heatsink design represents another exciting frontier. Researchers are investigating materials that can conduct heat more effectively at smaller scales, potentially leading to lightweight and highly efficient heatsinks that outperform traditional materials. As advancements in this field continue, they could dramatically change the landscape of thermal management in electronics, leading to more compact and efficient devices.

Evaluating the thermal performance of a heatsink and its interaction with the Lm380 amplifier is essential for ensuring reliability and efficiency. This evaluation typically involves measuring the temperature difference between the amplifier and the ambient environment while it operates under different load conditions. This data can then be compared against the maximum temperature ratings of both the amplifier and the heatsink material.

In addition to thermal evaluation, efficiency can also be quantified using metrics such as thermal resistance and thermal impedance, which provide insights into how well a heatsink can dissipate heat under operating conditions. Utilizing thermal simulation software can aid designers in predicting performance and identifying potential thermal issues before physical testing.

The integration of an Lm380 heatsink in electronic circuits is indispensable for maintaining system integrity and performance. Whether using it in audio amplifiers or other signal processing applications, the choice and installation of the appropriate heatsink cannot be overstated. By venturing into material selection, understanding proper installation techniques, and evaluating manufacturer reliability, users can ensure the longevity and efficiency of their electronic systems.

Furthermore, staying informed about the latest innovations in heatsink technology and understanding the environmental factors that impact performance can lead to significant improvements in design. As the field of electronics continues to evolve, so too will the methodologies for managing heat; thus, a commitment to continual learning and adaptation is essential for success in the ever-changing landscape of technology.

Ultimately, the diligent application of knowledge surrounding Lm380 heatsinks and thermal management will not only enhance the performance of devices but also offer advancements in sustainability, performance, and efficiency across a multitude of applications. By acknowledging the heating challenges and applying informed strategies, engineers and developers will contribute to the next generation of reliable and high-performing electronic systems.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!