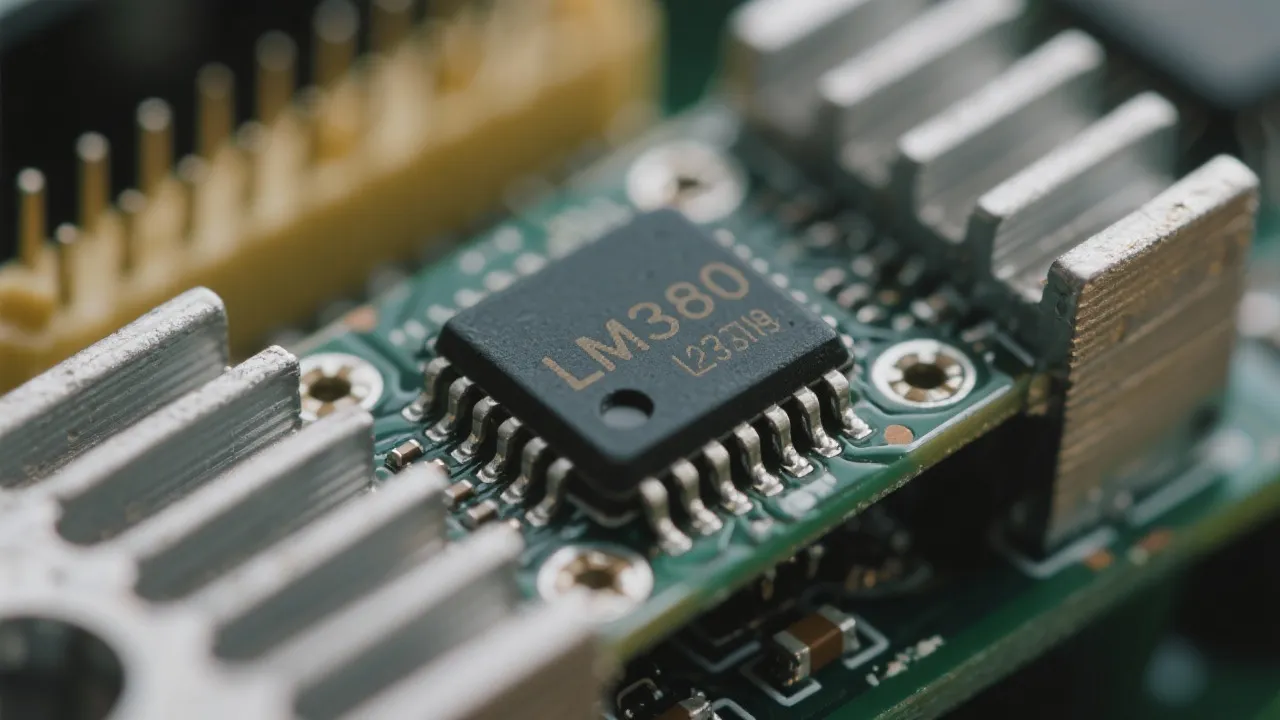

The importance of the LM380 heatsink in protecting and enhancing the performance of audio amplifiers cannot be overstated. This article delves into the role of the LM380 heatsink, a crucial component in thermal management for the LM380 audio amplifier IC, exploring why its effectiveness is vital for preventing overheating, ensuring reliability, and prolonging the service life of electronic devices.

In the realm of audio electronics, the LM380 audio amplifier IC stands out for its versatility and performance. However, one of the challenges presented by this chip is its potential to generate excessive heat during operation. This is where the LM380 heatsink becomes essential. This article provides an in-depth look at the indispensable role of the LM380 heatsink in maintaining optimal temperatures and ensuring the longevity and reliability of electronic devices featuring the LM380. With various factors influencing the selection and implementation of heatsinks, understanding their role becomes vital for anyone working with audio amplifiers.

Heatsinks play a crucial role in dissipating the heat generated by electronic components. When current flows through the LM380 IC, it inevitably produces heat, which, if unchecked, can lead to overheating and subsequent failure. The primary function of the LM380 heatsink is to draw this heat away from the IC and disperse it into the surrounding environment, keeping the temperature within safe operational limits. The concept of thermal management in electronic design not only involves immediate heat removal but also anticipates long-term stability and performance, creating a ripple effect in system reliability.

The efficiency of a heatsink relies significantly on its design and the material used. For the LM380, heatsinks made from aluminum or copper are preferred due to their excellent thermal conductivity. Ceramic and certain advanced composite materials are also gaining prominence in specialized applications due to their unique thermal properties and lightweight characteristics. The design typically features fins, which increase the surface area, facilitating better heat dissipation. Understanding the balance between size and thermal resistance is key to designing an effective heatsink for your application. The overall geometry of the heatsink, such as the chosen fin configuration (straight, curved, etc.), directly affects airflow and efficiency in thermal management.

Integrating a heatsink requires careful planning. It is important to consider factors such as ambient temperature and airflow around the device. In applications where space and weight are constraints, choosing the right size and type of heatsink becomes even more crucial. Often, adding a small fan can enhance the effectiveness of the heatsink, especially in confined spaces lacking natural airflow. Therefore, the implementation of a cooling strategy may also involve creating a well-balanced cooling loop to enhance airflow around the heatsink. Additionally, using temperature sensors can provide crucial feedback to dynamically adjust cooling methods based on operating conditions.

| Material | Conductivity | Advantages |

|---|---|---|

| Aluminum | 235 W/mK | Lightweight, cost-effective, corrosion-resistant, easy to manufacture into complex shapes |

| Copper | 398 W/mK | Superior thermal conductivity, durable, often utilized in high-performance applications |

| Ceramic | Varies by composition (generally lower than metal) | High-temperature stability, lightweight, can be designed for specific thermal and mechanical properties |

| Composites | Varies greatly | Unique thermal and mechanical benefits, tailored properties for specific applications, often lighter than metals |

To maintain optimal performance, regular inspection and cleaning of the heatsink are recommended. Dust and grime accumulation can significantly reduce the effectiveness of the heatsink. In cases of overheating, it is advisable to verify whether the heatsink is properly affixed and that all components are functioning as intended. Additionally, replacing thermal paste every few years can ensure optimal thermal conductivity. Examine the surrounding environment for other potential heat sources and revise cooling strategies if necessary.

Troubleshooting should also include checking for signs of stress on the circuit boards, as improper mounting of the heatsink can lead to physical strain that may affect the IC and surrounding components. If temperatures remain high despite proper installation and maintenance, consider upgrading to a more efficient heatsink design or adjusting the overall cooling strategy employed in the system.

The use of LM380 amplifiers spans various applications, from home audio systems to automotive audio installations. In high-power audio applications, you may find that the LM380 is pushed to its limits, especially during peak volume levels.

In consumer audio goods, such as an integrated amplifier or stereo receiver, managing heat spikes is crucial to maintaining performance. For instance, if the heatsink fails to regulate temperature appropriately, listeners may begin to notice distortion or intermittent clipping—conditions that can detract from the listening experience. Therefore, the integration of efficient heatsinks is paramount, particularly in home audio systems where prolonged usage is expected.

In automotive applications, where heat can rapidly build up due to confined space and ambient external temperatures, having a robust thermal management strategy is critical. Designers may implement additional cooling solutions, such as airflow ducts or temperature-controlled fans, alongside heatsinks to prevent the LM380 from overheating, ensuring that the amplification remains reliable whether driving the system at low or high volumes.

When considering cooling strategies for the LM380, two main aspects should be weighed: passive versus active cooling solutions. Passive cooling relies solely on the heatsink's capacity to dissipate heat through conduction and natural convection. On the other hand, active cooling incorporates fans or circulation methods to further expedite heat removal. Understanding the pros and cons of each approach can significantly influence the performance of the audio system.

Passive cooling solutions typically benefit from their simplicity, lower noise levels, and reduced complexity. For low power applications or devices operating in cooler environments, passive solutions may be sufficient. Alternatively, active cooling strategies are often employed in high-performance systems where heat generation is substantial. In these cases, the additional components may justify a slight increase in noise, offering enhanced longevity and operational stability.

Combining both strategies can also be effective. For example, using a robust passive heatsink in conjunction with a temperature-activated fan can strike a balance between silent operation and effective thermal management. The ideal approach often depends on specific design goals, such as cost, size constraints, and expected usage patterns.

The landscape of heatsink technology is continually evolving, driven by advancements in materials and thermal engineering. Recent developments explore the use of synthetic materials and nanotechnology to create novel heatsinks that promise improved performance. For instance, new polymer-based materials infused with thermal fillers are being researched, offering a potentially lighter solution without compromising on thermal management.

3D printing technology has also opened up new avenues for designing customized heatsinks tailored to specific applications. Such innovation allows for the creation of optimized geometries that can maximize surface area while minimizing weight—an essential consideration for modern audio equipment.

Moreover, smart heatsinks embedded with temperature sensors that provide real-time feedback for adaptive control systems are being integrated into high-performance devices. These innovations help maintain optimal thermal conditions by adjusting affiliations based on current operational demands. This responsiveness can significantly contribute to the extended lifespan of electronic devices.

In summary, selecting and integrating an efficient heatsink is crucial for the performance and durability of devices using the LM380 audio amplifier. By understanding the principles of thermal management and the specific requirements of the LM380, electronic enthusiasts and professionals can enhance the reliability and performance of their audio systems. Regular maintenance and proper installation practices further ensure that the LM380 and its accompanying heatsink operate at peak efficiency. The investment in a proper heatsink not only increases performance stability but can also protect the integrity of the entire audio setup, ensuring many years of reliable service.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!