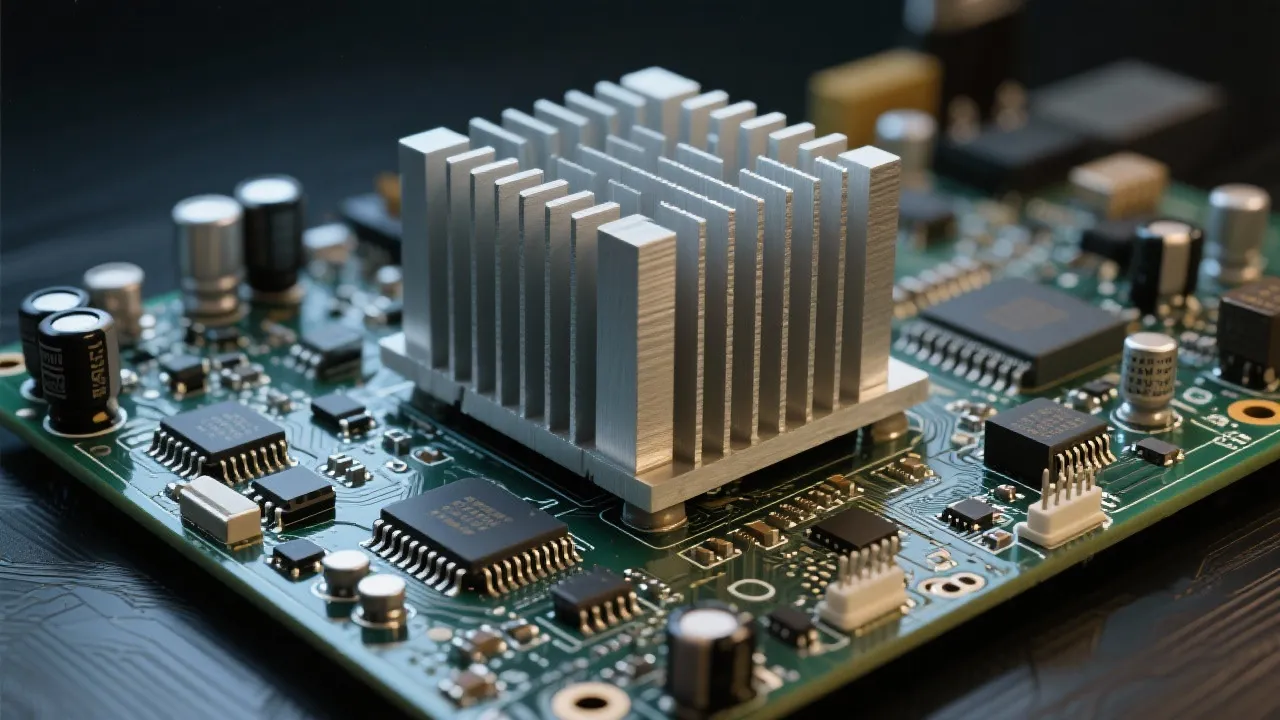

The LM380 heatsink is integral to enhancing the functionality and performance of the LM380 audio power amplifier by dissipating excess heat. The heatsink's efficiency directly affects the operational stability and longevity of the component, making it crucial in various electronic applications. This article delves into the importance, implementation, and considerations involved in selecting and using LM380 heatsinks effectively.

The LM380 is a high-fidelity audio power amplifier widely used in consumer electronics. Its compelling blend of low distortion and high gain makes it a popular choice among designers and hobbyists alike. Amplifiers are crucial components in audio systems, as they enhance audio signals to drive speakers and deliver clear sound. However, like all amplifiers, the LM380 generates heat, which can affect its performance and longevity if not managed efficiently. In a world where audio quality and durability are paramount, understanding the thermal aspects of the LM380 becomes crucial for both enthusiasts and engineers alike.

A heatsink is a critical component designed to dissipate the heat generated by electronic devices, ensuring optimal performance and preventing overheating. In the case of the LM380, an appropriate heatsink ensures that the amplifier operates efficiently without succumbing to thermal stress, which might otherwise lead to component failure. Efficient heat dissipation can prevent issues like thermal runaway, where increased temperature leads to excessive current draw, further raising the temperature and ultimately damaging the device. Consequently, employing a heatsink is not merely an added accessory but rather an essential component for maintaining reliability in circuits that dissipate significant power.

Selecting the right heatsink for the LM380 involves several considerations, including thermal resistance, the surface area of the heatsink, and ambient temperature conditions. The LM380 operates best at moderate temperatures, thus requiring a heatsink that can manage the thermal output effectively. Both the design and the specifications of the heatsink impact its performance in real-world applications. Below are detailed factors to consider:

Proper installation of the LM380 heatsink is paramount for ensuring effective heat dissipation. Failure to install the heatsink correctly can result in inadequate cooling, leading to potential overheating and damage. Follow this step-by-step guide for optimal results:

| Material | Thermal Conductivity | Cost | Durability |

|---|---|---|---|

| Aluminum | 205 W/mK | Low | High |

| Copper | 385 W/mK | Medium | High |

| Gold | 315 W/mK | High | Very High |

| Silver | 429 W/mK | Very High | Very High |

When using LM380 heatsinks, certain challenges might arise that need careful consideration:

A: The heatsink is necessary to manage the heat produced by the LM380 during operation, preventing thermal overload and ensuring efficiency. Without it, high temperatures can degrade the performance or even lead to failure of the amplifier.

A: Accurate installation, correct sizing, and thermal testing can help ensure the heatsink's efficacy. Monitoring the temperature during typical and peak usage cases can provide insights into whether the cooling solution is sufficient.

A: Both aluminum and copper are excellent, but the choice depends on budget and thermal management needs. For high-performance applications, copper may be ideal; for cost-sensitive designs, aluminum often suffices.

The LM380 is not just an abstract piece of technology; it has practical applications across various sectors. Its robustness and quality make it suitable for high-fidelity audio systems, including home audio systems, professional sound reinforcement equipment, and even musical instrument amplifiers. The following examples illustrate its versatility and importance in the audio landscape:

As technology evolves, so do the materials and designs employed in heatsink manufacturing. Advanced heatsink technologies are increasingly utilized to enhance cooling performance without increasing size or weight dramatically. Some notable advancements include:

The field of audio amplification is continuously advancing, driven by emerging technologies and consumer demands for better sound quality. As digital signal processing, increasing battery efficiency, and improvements in materials science progress, the future of amplifier designs - including those like the LM380 - will likely include:

In conclusion, selecting and installing the right LM380 heatsink is crucial for optimizing the amplifier's performance. Proper thermal management helps prevent overheating, ensuring audio fidelity and prolonging the life of the device. Understanding the key aspects of thermal management and thoughtfully addressing potential concerns go a long way in enhancing the reliability and efficiency of electronic devices. As advancements continue in both amplifier technology and heatsink design, users can look forward to high-quality audio experiences powered by smart, efficient solutions. The LM380, along with its compatible heatsink solutions, remains a testament to quality in the ever-evolving landscape of audio amplification.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!