The LM380 heatsink is a crucial component for the proper functioning of audio amplifiers, ensuring efficient heat dissipation and the prevention of thermal overload. Renowned for its role in managing heat in amplifiers using the LM380 integrated circuit, the heatsink is integral in maintaining optimal performance and longevity of audio equipment.

In the realm of audio amplification, the LM380 heatsink holds a vital position. Essentially, it is designed to dissipate the excess heat generated by the LM380 integrated circuit, a component known for its application in low-power audio amplifiers. The primary function of this heatsink is to keep the temperature within a safe range to ensure both efficiency and longevity of audio devices. As audio equipment continues to advance, the need for effective heat management has become increasingly critical to maintain performance and reliability. With the rising power demands of modern amplifiers, understanding the role and functioning of heatsinks like those for the LM380 is more essential than ever.

Heat management is paramount in electronic devices, especially within audio systems that exert significant power. If left unchecked, excessive heat can lead to component failure or reduced lifespan of devices. The LM380 heatsink mitigates these risks by facilitating effective thermal management, thereby preventing damage from overheating. This heat dissipation is crucial because, in many audio applications, amplifiers may run continuously for long periods. Therefore, understanding how to effectively manage heat can directly impact the reliability and stability of the performance of the equipment. Furthermore, prolonged operation under high temperatures can accelerate wear on electronic components, which can often lead to costly repairs or replacements.

The LM380 is a popular integrated circuit used in audio amplification due to its simplicity and low power requirements. It can amplify audio signals and is utilized in various applications, from radio amplifiers to small home audio systems. The integration of an effective heatsink with LM380 is crucial to leverage its full potential while maintaining operational reliability. This circuit is designed to work efficiently at various power levels, making it versatile for all sorts of audio devices. However, without a proper heatsink to manage the thermal output, even minor fluctuations in performance can lead to significant issues, such as distortion in audio output or even thermal shutdown in severe cases. Understanding its operational parameters and typical applications further illustrates the importance of heat management in circuits like the LM380.

Proper installation and regular maintenance of the LM380 heatsink are essential to ensuring that it operates effectively over time. This not only includes the initial setup but also extends to ongoing care to prevent potential thermal issues.

The selection of a heatsink is essential for achieving optimal thermal performance in any audio amplification project. This comparative analysis highlights different types of heatsinks suited for applications utilizing the LM380 integrated circuit.

| Heatsink Type | Material | Efficiency | Application |

|---|---|---|---|

| Standard LM380 Heatsink | Aluminum | High | General audio amplifiers |

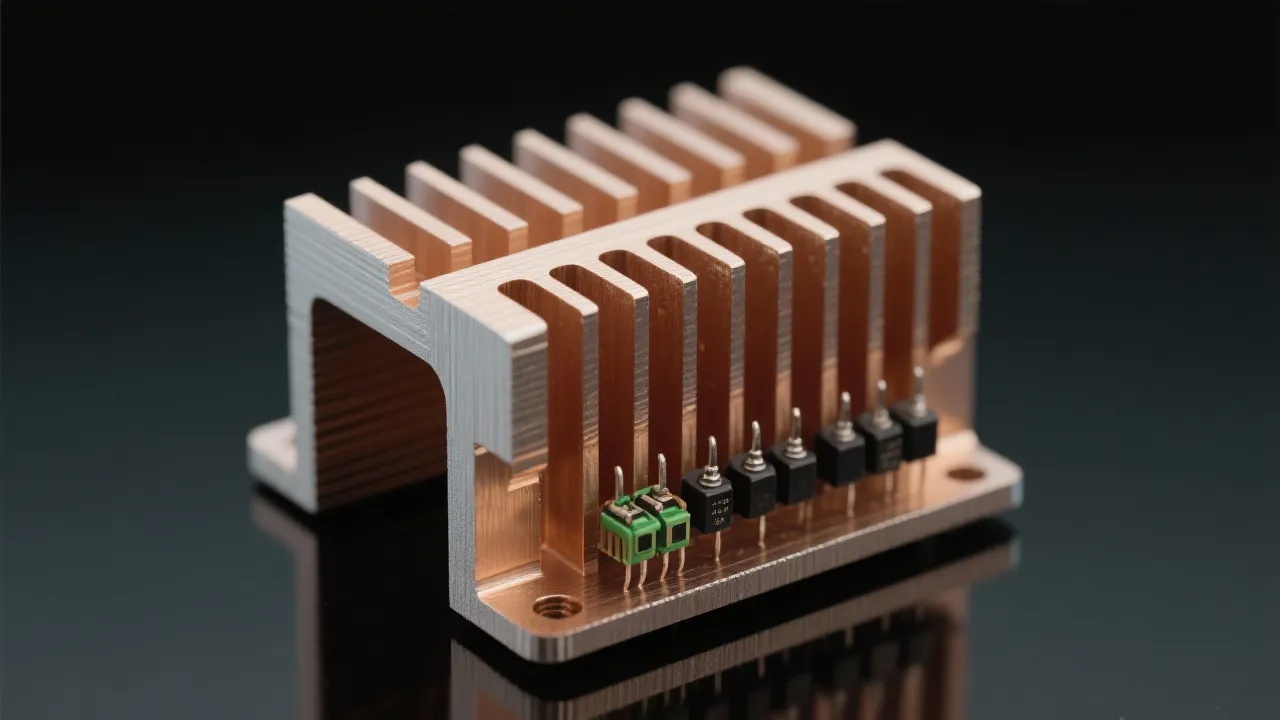

| Advanced Copper Heatsink | Copper | Very High | High-end audio systems |

| Low Profile Heatsink | Aluminum | Medium | Compact designs where space is a constraint |

| Active Cooling Heatsink | Mixed (Aluminum with fan) | Very High | High power applications requiring effective cooling |

The LM380 heatsink stands out as a fundamental component in audio amplification systems, offering the thermal management required to maintain both performance and durability of electronic devices. By ensuring proper installation, routine maintenance, and understanding its specifications, users can significantly optimize their audio systems. As technology continues to evolve, the design and efficiency of heatsinks will also advance, providing even better solutions for managing excessive heat in increasingly powerful audio applications. Awareness of best practices, innovations in materials, and a commitment to quality assurance play definitive roles in fostering an environment where audio systems can thrive and deliver outstanding performances for years to come.

When delving deeper into the realm of audio amplification, particularly with devices utilizing the LM380 integrated circuit, there are several additional considerations to keep in the forefront.

While standard heatsinks are effective, there are advanced thermal management techniques available that can further enhance the performance of audio amplifiers. These methods include:

Different audio applications may demand varied thermal management solutions. For example, portable audio amplifiers may prefer lightweight aluminum heatsinks, while stationary high-power audio systems may benefit greatly from copper or active cooled options due to their improved overall heat dissipation. Understanding the unique requirements of each application is crucial in selecting the appropriate thermal management strategy and ensures long-term reliability and performance consistency.

In summary, while the LM380 heatsink plays a vital role in ensuring the adequate performance of audio amplification systems, exploring further enhancements through advanced thermal management solutions can yield significant advantages. Adapting to the changing landscape of audio technology and consumer demands can make a considerable difference in effectiveness, reliability, and user satisfaction.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!