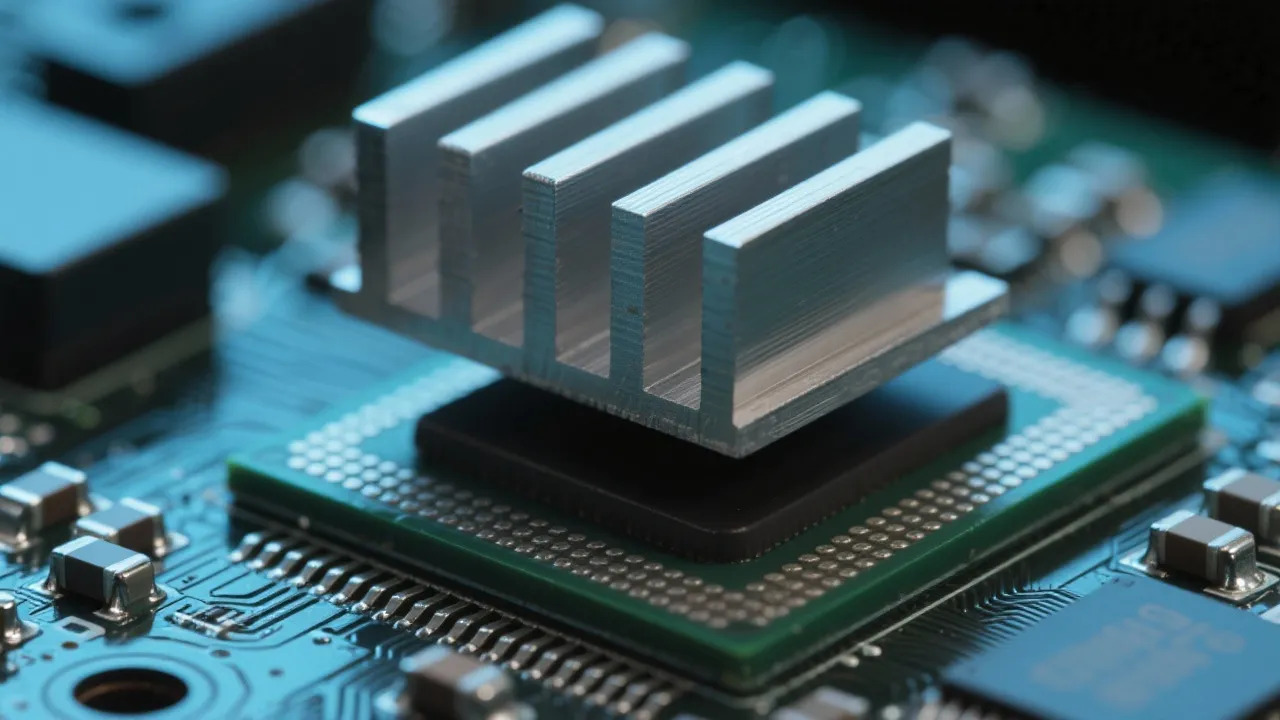

The Lm380 heatsink plays a vital role in managing the thermal output of electronic devices. As heat dissipation is crucial for maintaining optimal performance and extending the lifespan of electronics, this guide delves into the significance of heatsinks, particularly the Lm380 model. We also explore various installation methods and address common queries related to heatsink utilization.

In the world of electronics, effective heat management is crucial. A heatsink's primary function is to dissipate heat produced by electronic components, ensuring they operate within safe temperature limits. Overheating can lead not only to decreased performance but also to permanent damage of sensitive components. The Lm380 heatsink, a component favored for its efficiency, is pivotal in maintaining the functionality and longevity of various electronic devices, particularly audio devices where the Lm380 integrated circuit (IC) often resides. Given the importance of thermal management, this exploration delves deep into the various aspects of heatsink technology, specifically the Lm380 heatsink functionality and performance, while drawing contrasts with related components in the realm of electronic cooling solutions.

Before delving deeper into the specifics of the Lm380 heatsink, it is essential to understand how a heatsink works fundamentally. A heatsink operates on the principle of thermal conduction, whereby heat flows from a hot object to a cooler one until thermal equilibrium is achieved. By providing a larger surface area for heat exchange with the surrounding environment, heatsinks can effectively dissipate the heat generated by the electronic components, which is critical for maintaining efficient operation.

Heatsinks are constructed to maximize air exposure through design features such as fins, pins, and other elements that increase their surface area. As air flows over these surfaces, it takes away heat, which lowers the temperature of the heatsink, consequently cooling the device mounted on top of it. Furthermore, the efficiency of a heatsink can be drastically influenced by factors such as ambient temperature, airflow, and the material from which it is constructed.

The Lm380 heatsink is specifically designed to manage the thermal output of devices equipped with the Lm380 audio amplifier IC, one of the most popular chips used in various consumer electronics such as home audio systems and portable speakers. Known for its compact size and effectiveness, the Lm380 is favored not only for its audio performance but for its ability to drive loudspeakers effectively without distortion. However, like many other ICs, it generates heat during operation, necessitating an efficient cooling solution to prevent thermal throttling and potential damage.

This aspect of the Lm380 heatsink is illustrative of broader trends in the electronics industry. As devices become more compact and multi-functional, the thermal output per unit area has increased, heightening the necessity for advanced thermal management solutions. The efficient design and integration of the Lm380 heatsink exemplify the necessary evolution in consumer electronics, ensuring performance is not compromised.

Heatsinks, including the Lm380 model, are engineered to increase the surface area that interacts with the surrounding air, allowing for more effective heat dissipation. Made from materials with high thermal conductivity such as aluminum or copper, the Lm380 heatsink often features a finned structure. These fins maximize the surface area, optimizing the heat dissipation process...

These design considerations are not merely academic; they have practical implications for end users. For instance, an Lm380 heatsink's structure directly correlates to the efficiency with which an amplifier can operate over extended periods, even under demanding output conditions. Manufacturers often opt to design fins of varying lengths and orientations to enhance airflow dynamics, therefore improving the cooling action.

For instance, an increase in the height of fins can enhance the cooling capability in scenarios where airflow is both atmospheric and forced (using fans). On the other hand, for compact designs where space is severely restricted, optimizing the layout and number of fins can offer substantial gains in thermal performance.

Proper installation is key to ensuring that the Lm380 heatsink performs optimally. Here is a step-by-step guide for installing an Lm380 heatsink on a printed circuit board (PCB):

In addition to these foundational steps, it’s critical during installation to apply a thin layer of thermal paste or thermal adhesive, which fills microscopic gaps between the heatsink and the IC. This interface ensures better heat conduction. Users should also consider the ambient environment; if the device operates in a closed space, implementing additional ventilation strategies can aid in thermal management.

While aluminum is the very common material for heatsinks due to its lightweight nature and good thermal conductivity, some applications may require copper. Copper, albeit heavier, offers superior thermal performance, making it ideal for high-demand scenarios...

The differences in these materials are not solely determined by weight but also by mechanical properties, corrosion resistance, and cost-effectiveness. In applications where weight is critical, such as in mobile devices, aluminum is often favored despite its lower thermal conductivity. Conversely, in applications with stringent thermal performance demands—like high-fidelity audio amplifiers or high-performance computing—copper or even composite materials that integrate both aluminum and copper may be preferred.

It’s also worth highlighting some emerging materials in heatsink technology. Metal Matrix Composites (MMCs), for example, offer an exciting new frontier. These materials can combine lightness with excellent thermal conductivity, potentially offering significant advantages over traditional materials.

The effectiveness of a heatsink is not solely defined by its material or design but also by its integration into the device. The Lm380 heatsink excels by striking a balance between these factors, providing an efficient means to maintain device reliability and performance over extended periods...

Heatsinks must be seen in the context of the entire thermal management system. This includes not only the heatsink itself but also the placement of components, airflow design, and potential interactions with other thermal dissipation technologies, such as heat pipes or active cooling systems. Implementing a holistic approach to thermal management can lead to substantial improvements in device performance. Moreover, recent advancements in modeling software allow engineers to simulate thermal performance, paving the way for optimal heatsink designs tailored to specific applications.

When comparing heatsink solutions, it's essential to evaluate thermal performance, cost, weight, and ease of installation. In the market, alternatives to the Lm380 heatsink include active cooling solutions such as fans, which can provide improved cooling performance but at the cost of increased complexity and potential points of failure.

Active cooling systems are typically more effective in environments with high thermal loads, while passive systems like the Lm380 heatsink excel in simpler applications, where space, budget, and noise are primary concerns. Additionally, passive systems often require no power, further simplifying the design of the device.

The future of heatsink technology is set to evolve with advancements in material science and thermal engineering. Research into nanomaterials, for instance, may lead to the development of lighter and more efficient heatsinks that can operate in more extreme conditions, or even adaptive heatsinks that can change their properties based on temperature variations.

Also, the increasing complexity of electronic components and systems is pushing designs towards hybrid cooling solutions, combining both active and passive elements to improve overall thermal management efficiency further. This hybrid approach could revolutionize how heatsinks are integrated into various applications, from mobile devices to large servers.

In addition to the heatsink material itself, attention must be paid to the thermal interface materials (TIMs) used in the assembly. TIMs, such as thermal pastes, pads, or gels, play a crucial role in facilitating thermal conductivity between the heatsink and the component it cools, such as the Lm380 IC.

Different types of TIMs come with various thermal conductivities, mechanical properties, and ease of application. For instance, thermal pastes often provide superior conductivity and are useful for high-performance applications. In contrast, thermal pads offer ease of use and repeatability but might fall short in thermal performance under extreme conditions. Development in TIM technology is another significant area to watch, as improving these materials can lead to more efficient overall thermal management solutions.

As with many components in electronics, environmental considerations are taking center stage in heatsink design and manufacturing. A growing number of manufacturers are looking into ways to create heatsinks from recyclable materials or deploying processes that reduce environmental impact. Recycling and reusing metals like aluminum and copper can lead to significant sustainability improvements in the production of heatsinks, aligning product life cycle management with corporate responsibility initiatives.

Additionally, new technologies such as 3D printing are entering the mainstream in heat sink production. These methods not only reduce waste during manufacturing but also enable more innovative designs that were previously impossible with traditional manufacturing techniques.

Q: Why is a heatsink necessary for the Lm380 IC?

A: Heatsinks are essential to prevent overheating, which could compromise the IC's functionality or cause permanent damage. Heat can degrade performance and subsequently lead to failure in critical applications.

Q: How do I choose the right heatsink?

A: Consider factors such as the IC's power rating, the thermal conductivity of the heatsink material, space constraints within your device, and the application's cooling needs.

Q: Can I use an Lm380 heatsink in other applications?

A: Yes, while it's optimized for the Lm380 IC, it can be used in similar applications requiring efficient heat dissipation, demonstrating versatility across various electronic designs.

Q: What is the impact of poor heatsink design on performance?

A: A poorly designed heatsink can lead to overheating, resulting in thermal throttling, decreased performance, and potential component failure, jeopardizing the overall reliability of the electronic device.

In conclusion, the Lm380 heatsink is indispensable for maintaining a stable thermal environment for Lm380 ICs. By choosing the correct design and material, and ensuring proper installation, users can significantly improve their electronic devices' performance and lifespan. An in-depth understanding of the factors affecting heatsink performance, as detailed in this exploration, equips engineers and designers to make informed decisions that optimize their applications, ultimately contributing to the evolution of electronic devices in an increasingly demanding market.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!