This guide delineates the role of heatsinks in optimizing the performance of the LM380 amplifier. The LM380 is a power audio amplifier chip renowned for its simple design and efficacy in low-power applications. Effective heat management using heatsinks ensures these amplifiers operate efficiently without overheating, thereby extending their lifespan and improving audio performance.

The LM380 is a cost-effective and versatile power audio amplifier designed for driving low-power speakers. This integrated circuit operates commonly in consumer electronics, offering a compact solution for amplifying audio signals. However, like all electronic components, it generates heat during operation, which, if not managed properly, can lead to diminished performance or even damage. A heatsink is a critical component that dissipates this excess heat, ensuring that the LM380 operates at its optimal temperature. Proper integration of an LM380 heatsink can significantly enhance performance and longevity, allowing users to enjoy high-quality audio without interruption.

Heat is one of the very challenging aspects of maintaining the integrity of electronic devices. Excessive heat can lead to premature failure of components, intermittent performance issues, and potentially hazardous operating conditions. It is essential to include adequate heat management solutions in the design of electronic systems. Heatsinks are designed to absorb and dissipate heat away from the main circuitry, thereby maintaining a stable operating environment for the component. By keeping components cool, heatsinks play a crucial role in enhancing overall system reliability and performance.

In audio applications, where the clarity and fidelity of sound quality are paramount, effective heat management becomes even more critical. The LM380, when subjected to prolonged use at high volumes, is prone to heating up. Without proper cooling, this can not only lead to audio distortion but can also affect the quality of the sound produced by the speakers. Protecting the amplifier from excessive heat ensures that it operates within the specifications laid out by its manufacturer, thereby promoting better performance over time. Additionally, heat management mitigates risks such as component failure due to overheating, leading to cost savings on repairs and replacements.

When selecting a heatsink for the LM380 amplifier, it is essential to consider multiple factors such as thermal resistance, size, material, and the surrounding environment. Thermal resistance is a measure of the heatsink's effectiveness in transferring heat away from the component and is usually expressed in degrees Celsius per watt (°C/W). A lower thermal resistance value indicates a more efficient heatsink, which is vital for ensuring that the LM380 remains within its operating temperature limits during use.

The size of the heatsink should be appropriate for the application it is being used in. A larger heatsink, typically with more surface area, will dissipate heat more effectively than a smaller one. However, the heatsink must fit securely within the device it is being installed in while allowing for sufficient airflow around itself to facilitate heat dissipation. In situations where space is a constraint, it may be beneficial to look for compact designs that still offer adequate cooling performance.

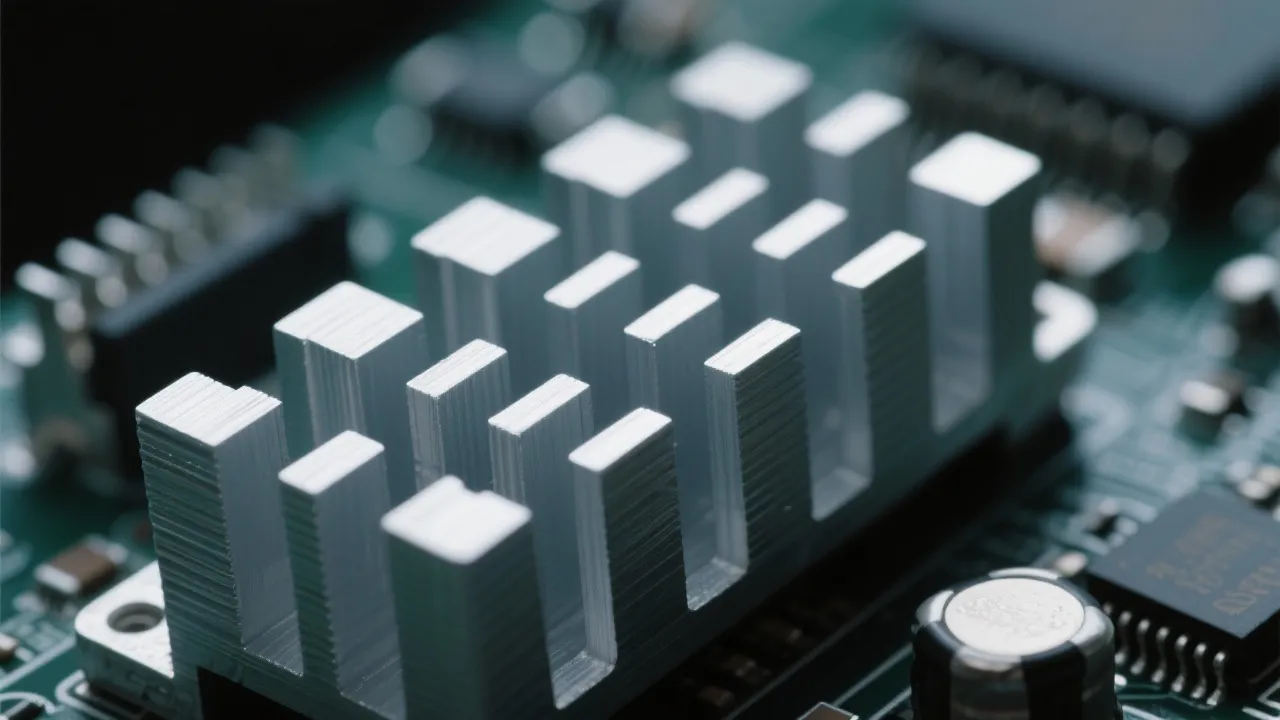

Material selection is another critical consideration when choosing a heatsink for the LM380. Aluminum is a common material used for heatsinks due to its excellent thermal conductivity and affordability. It is lightweight and can be easily fabricated into various shapes and sizes. Furthermore, anodized aluminum provides additional resistance to corrosion, enhancing durability.

Copper heatsinks, while more expensive and heavier than aluminum, offer superior thermal conductivity. They are often preferred in high-performance applications where minimizing thermal resistance is critical. When choosing between aluminum and copper, consider the trade-offs between cost, weight, and thermal performance based on your specific application requirements.

Lastly, consider the environment in which the amplifier will be used. If the LM380 is to be installed in a location susceptible to high ambient temperatures or poor ventilation, a more robust heatsinking solution may be necessary to ensure adequate cooling. Overall, carefully assessing these factors can lead to choosing the optimal heatsink that complements the LM380's design, ensuring a snug fit for maximum heat transfer.

Attaching a heatsink to the LM380 is a straightforward process, but it must be done with care to prevent damage to the chip. Here's a step-by-step guide:

Following these steps will help ensure proper thermal management for the LM380 and prevent overheating, thereby maintaining consistent audio quality and prolonging the lifespan of the amplifier. Regular checks and maintenance during the life of your circuit can also help maintain temperature efficiency, especially in environments where dust accumulation occurs.

The integration of a heatsink can substantially affect the operational efficiency of the LM380. It allows the amplifier to sustain continuous operation at higher volumes without overheating. This, in turn, results in clearer and more stable audio output while preserving the integrity of the semiconductor. When the amplifier is allowed to operate in a cooled state, it can deliver higher voltage output to speakers without distortion, significantly improving sound quality.

A properly selected and installed heatsink mitigates the risk of thermal runaway—a state where increasing temperature leads to greater current flow, subsequently generating even more heat, which can overwhelm thermal regulation circuits. Regular operation in a cooler state enhances the reliability of electronic components, extending their lifespan and ensuring that power delivery to speakers remains reliable.

Moreover, effective temperature management can improve the operational characteristics of the amplifier. For example, with a heatsink that adequately dissipates heat, the LM380 can achieve better low-frequency response—this means that music with deep bass sounds can be amplified with reduced distortion, enhancing listener experience. Users can therefore enjoy their music with less worry about amplifier damage due to overheating, leading to a steadier performance over time.

| Type of Heatsink | Advantages | Disadvantages |

|---|---|---|

| Aluminum | Lightweight, affordable, excellent thermal conductivity. | Moderate performance under very high temperatures. |

| Copper | Superior thermal conductivity, robust heat dissipation. | Expensive, heavier than aluminum. |

| Ceramic | Non-conductive, resistant to high temperatures. | Fragile, limited thermal conductivity compared to metals. |

| Composite Materials | Combines the advantages of various metals for enhanced performance. | May be costly and less common than pure metal heatsinks. |

This comparative analysis highlights the strengths and weaknesses of various heatsink materials, allowing users to make informed decisions based on their unique requirements. By evaluating these options, users can select a heatsink that will best support the LM380’s operational characteristics while considering trade-offs regarding cost, weight, and expected thermal performance.

Using a heatsink with your LM380 amplifier is paramount for optimal performance and longevity. Properly managing heat through an efficient heatsink not only enhances the thermal management of the device but also ensures that the audio output remains stable and free from distortion. By understanding the importance and application of heatsinks, users can maximize their investment in the LM380 and related audio amplification systems. This understanding fosters not only better performance from the amplifier but also greater satisfaction in the overall listening experience.

Furthermore, the ability to make informed selections regarding heatsinks, coupled with proper installation and maintenance, can lead to more confidence in electronic projects, enabling hobbyists and engineers alike to push the boundaries of audio technology. As the demand for high-fidelity audio continues to evolve, the role of effective heat management in amplifiers such as the LM380 will undoubtedly remain a vital aspect of audio electronics design, reinforcing the importance of thermal management in this dynamic field.

Ultimately, anyone venturing into audio amplification, whether as a hobbyist or professional, should prioritize heatsink selection and implementation, ensuring that their projects not only meet their immediate audio needs but also stand the test of time. A well-cooled LM380 amplifier is the key to a satisfying audio experience, enhancing enjoyment in every note and beat produced.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!