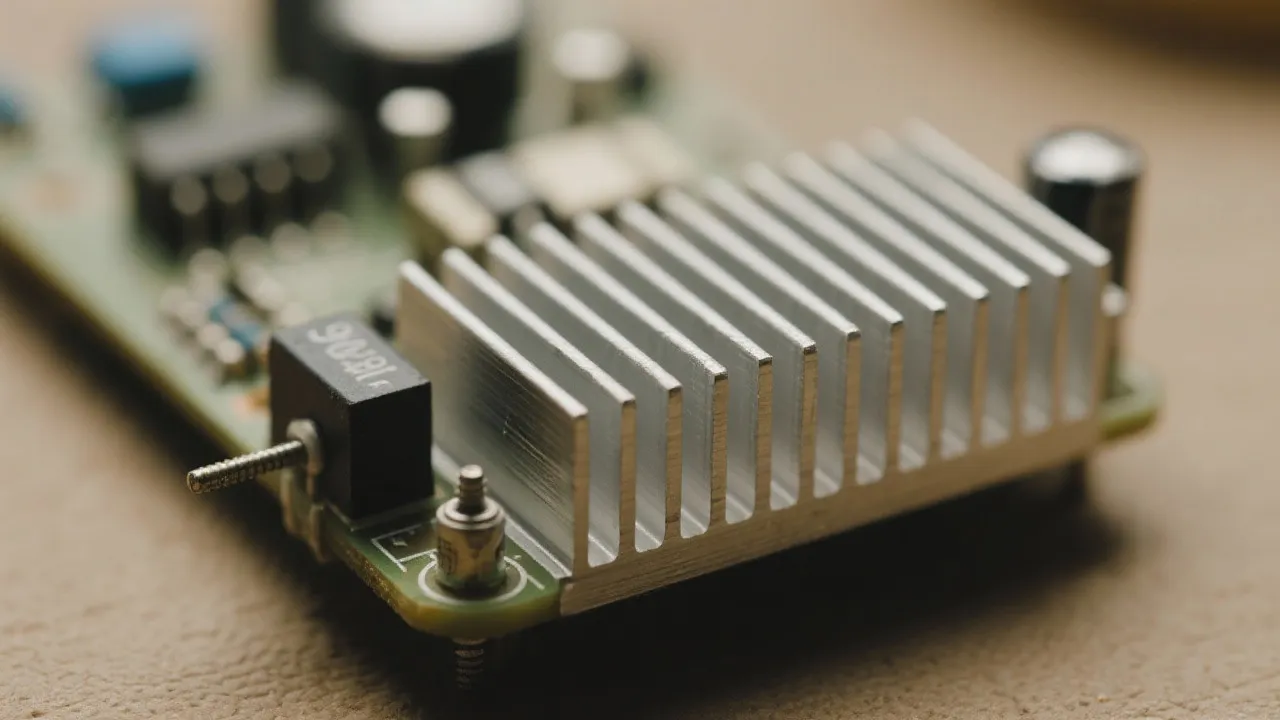

This article dives into the importance of the LM380 heatsink, a crucial component for the LM380 audio amplifier chip used in various electronic applications. The LM380 is designed for use in low-power audio amplification, and an appropriate heatsink is vital for maintaining efficiency and preventing overheating, which can compromise the performance and longevity of the amplifier.

The LM380 is a widely recognized audio amplifier chip renowned for its reliability and efficiency in low-power applications. It requires a proper heatsink to function optimally, given the heat generation during its operation. The LM380 heatsink plays a pivotal role in dissipating this heat, ensuring the amplifier's performance and longevity remain uncompromised. In this detailed exploration, we examine the nuances of using an LM380 heatsink, its benefits, and considerations for selecting the right one for your audio amplification needs. Understanding these areas is essential for maximizing system efficiency and performance, paving the way for a deeper appreciation of audio technology.

Excessive heat is a common challenge in electronic circuits, particularly in components like the LM380 that are involved in amplification processes. An efficient heatsink is not merely a hardware accessory; it is a crucial component that significantly impacts the overall performance of the amplifier. It helps in the dissipation of heat by increasing the surface area available for heat transfer. This is crucial for maintaining the integrity of the chip and the quality of the audio output. The LM380's operational integrity is directly tied to temperature management; without an efficient heatsink, the LM380 amplifier risks thermal runaway, which could lead to malfunction or failure. In this context, it is important to understand how temperature affects electronic components, specifically audio amplifiers, and why active thermal management should be a priority for designers and users alike.

When selecting a heatsink for the LM380, several factors come into play:

The LM380 is commonly used in various audio equipment, from compact speakers to complex home audio systems. In these settings, the role of the heatsink extends beyond simple heat management. It affects total harmonic distortion (THD) and noise performance of the amplifier. For audiophiles and professionals, the choice of an appropriate heatsink can make a notable difference in sound quality. The thermal performance of the heatsink directly relates to the amplifier's operational stability, impacting factors such as signal linearity and sound fidelity. Understanding how temperature affects the physical and performance characteristics of audio equipment enriches the design choices and end-user experiences.

| Heatsink Material | Thermal Conductivity | Cost Efficiency |

|---|---|---|

| Aluminum | High | Cost-effective |

| Copper | Very High | Expensive |

| Composite Materials | Moderate to High | Varies by composition |

The primary purpose is to dissipate heat generated during the operation of the LM380, thereby preventing overheating and ensuring efficient performance. Overheating can lead to reduced audio quality, potential damage to the amplifier, and shortened operational lifespan.

Material composition, design efficiency, and mounting configuration are critical factors influencing heatsink selection, along with environmental aspects such as ambient temperature and humidity levels. Additional considerations might include the expected load and dynamic operating conditions that your audio application will face.

The design of the heatsink affects thermal management, which in turn influences the amplifier's distortion and noise levels, impacting overall audio quality. A well-designed heatsink minimizes thermal fluctuations, contributing to more stable amplifier behavior across varying conditions. When distortion is minimized, the audio output remains clear and faithful to the source material.

Materials like aluminum are preferred for their lightweight and cost efficiency, whereas copper is chosen for its superior heat conductivity despite the higher cost. For high-performance systems, combining both materials through hybrid constructs offers a great balance between cost and thermal management.

Absolutely. A heatsink that fails to adequately dissipate heat can cause the LM380 to operate beyond its thermal limits, which may lead to premature failure, performance degradation, or unexpected shutdowns. Design considerations should prioritize optimal airflow and adequate surface area for transferring heat to the environment.

As technology advances, the efficiency and designs of heatsinks evolve, incorporating innovations that drive both performance and aesthetic appeal in electronics such as those using LM380 amplifiers. Recent trends show a shift towards more energy-efficient designs in the face of rising global temperatures and climate concerns. Industry standards emphasize sustainability and material waste reduction, influencing the direction of heatsink development and manufacturing processes. Organizations dedicated to exploring green technology often investigate alternative materials or fabrication techniques that reduce the carbon footprint associated with production. Staying informed about these trends, such as the usage of recyclable materials or the principles of energy-efficient design, can benefit manufacturers and enthusiasts significantly as they explore the LM380's capabilities in audio amplification.

Successfully integrating a heatsink with the LM380 involves several steps that ensure optimal functioning:

Several instances in the audio industry serve as demonstrative successes related to heatsink implementation with the LM380. Here are a few notable examples:

Looking ahead, the design and function of heatsinks will continue to evolve, spurred on by innovations in both thermal management technologies and environmental considerations. Advancements in manufacturing techniques, such as 3D printing, may open new avenues for creating more efficient geometries that enhance heat dispersion. Moreover, trends toward miniaturization in electronics might drive further exploration into micro-heatsinks or more sophisticated materials that offer superior thermal performance in smaller packages.

As the audio industry embraces these technologies, engineers and designers must remain proactive in assessing the needs of amplifiers like the LM380. By balancing thermal management, performance, and sustainability, the future of heatsinks can not only meet the demands of consumers but also contribute positively to the broader challenges of energy consumption and environmental responsibility.

Understanding the role and selection criteria of the LM380 heatsink is paramount for anyone involved in designing or maintaining audio systems. With the correct heatsink, the LM380 amplifier continues to be a robust and reliable component in the world of audio technology, providing both exceptional performance and longevity. In an era where sound quality and system durability are paramount, choosing the right heatsink can be the difference between an average performance and an extraordinary audio experience. Emphasizing thoughtful design, effective materials, and innovative engineering will ensure that audio systems not only meet current demands but also adapt to meet the future challenges of audio amplification in an ever-evolving technological landscape.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!