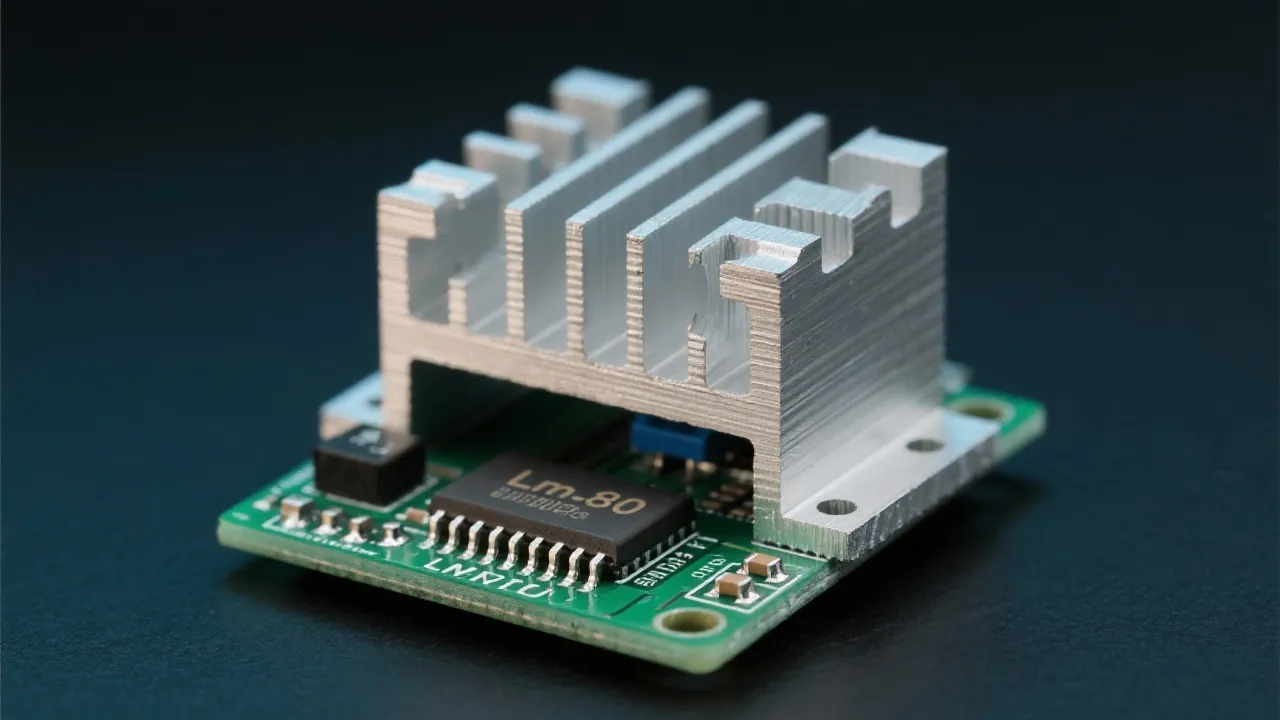

This article delves into the essential role of an Lm380 heatsink in maintaining optimal performance and longevity of audio amplifier circuits. Utilizing a heatsink for the Lm380 integrated circuit is crucial, as it helps manage heat dissipation and ensures the efficient functioning of the amplifier. Proper thermal management is central to electronic circuit reliability, making heatsinks a vital component in electronic design.

The Lm380 is a popular audio amplifier integrated circuit known for its robust performance in producing quality audio outputs. Its widespread usage in audio applications signifies the importance of managing thermal conditions effectively. Herein lies the role of an Lm380 heatsink, a component designed to dissipate heat efficiently, thus safeguarding the performance of the circuit. Without effective thermal management, the potential for overheating could lead to distortion in sound output or, worse, circuit failure.

Integrated circuits like the Lm380, while efficient, tend to generate substantial heat during operation. This heat, if not managed properly, can lead to thermal stress, impacting both the performance and lifespan of the circuit. Heat buildup can alter the operational characteristics of the circuit, leading to performance degradation, and can even cause failure through thermal runaway—an uncontrolled increase in temperature that can permanently damage the device. Introducing a heatsink helps in maintaining the device's temperature within safe operating limits, thereby not only enhancing performance but also extending its life. As amplifiers are often pushed to their limits, particularly in dynamic audio scenarios, the efficiency of heat dissipation becomes a pivotal factor in their design and utility.

Heatsinks for Lm380 are typically made from materials with high thermal conductivity, such as aluminum and copper. Aluminum is widely used due to its lightweight and cost-effective nature, while copper offers superior thermal conductivity but at a higher price point. The design of heatsinks generally involves a large surface area to volume ratio, often featuring fins or other methods to increase the surface area available for heat dissipation. This enhanced surface area facilitates more efficient transfer of heat from the device into the surrounding air. The effectiveness of a heatsink can be greatly influenced by its design; therefore, various configurations are employed depending on specific application requirements. For instance, some heatsinks are designed with attached fans or may be simply mounted in a way that maximizes natural convection currents.

Lm380 heatsinks are predominantly used in audio amplifiers across various consumer electronics, including home theater systems, musical equipment, and automotive audio systems. In each of these applications, maintaining device reliability and audio quality is paramount, making effective heatsinking practices indispensable. For instance, in a car audio system, the limited space and high ambient temperatures necessitate a carefully selected heatsink that can handle elevated thermal loads. Similarly, within musical amplifiers, where extended play periods are common, thermal dynamics must be managed meticulously to prevent overheating.

When designing electronic circuits that utilize the Lm380, it’s vital to incorporate the heatsink during the initial design phase. This ensures other components are positioned to maximize airflow and prevent hotspot formation around the circuit. Furthermore, the integration should also account for potential upgrades in power requirements that might demand more rigorous heat management strategies. Redesigning a circuit to accommodate a heatsink after completion can be challenging, impacting both the timeline and cost of projects. Therefore, proactively addressing thermal management can lead not only to better device performance but also to more efficient design processes.

| Consideration | Top Practice |

|---|---|

| Thermal Interface Material | Use high-quality thermal paste to ensure effective heat transfer and minimize thermal resistance between the Lm380 and the heatsink. |

| Environment | Keep the device in environments with adequate ventilation. A restricted airflow setup can greatly increase thermal challenges. |

| Maintenance | Regularly check for dust accumulation that could impair cooling efficiency. Dust can create insulating barriers that trap heat. |

| Thermal Monitoring | Implement temperature sensors as part of a feedback loop to provide real-time thermal data, triggering alarms or shutdowns if temperatures exceed safe operating limits. |

The primary function is to dissipate unwanted thermal energy generated during operation to prevent overheating and ensure stable audio performance.

While it can operate without a heatsink, it risks reduced performance and potentially shortened lifespan due to inadequate heat management. As the circuit approaches its maximum output capacity, the likelihood of overheating significantly increases.

If the circuit operates at higher power levels or resides in an enclosed space with limited airflow, a heatsink is advisable. Additionally, experimenting with different power configurations can help gauge the thermal response of the circuit.

Insufficient cooling may result in thermal stress leading to performance issues such as distortion, signal clipping, or complete shutdown of the device. In severe cases, it may even cause irreversible damage to the integrated circuit.

Fans can be mounted strategically to blow air directly across the heatsink or to create a path of forced convection. This setup can enable the heatsink to dissipate heat more effectively, especially in cramped conditions.

As electronic devices become more compact and powerful, the demand for effective thermal management continues to increase. Advanced techniques and technologies are being implemented to enhance the cooling efficiency of Lm380 circuits further, ensuring they can operate safely under demanding conditions. Among these techniques, the following stand out:

While passive cooling with heatsinks is effective, active cooling solutions can significantly enhance heat dissipation. This includes the use of fans or even liquid cooling systems in more advanced designs. Active cooling engages mechanical devices to maintain a consistent airflow or to circulate a cooling medium, thus preventing thermal buildup more effectively. In scenarios where high power is drawn consistently, active cooling systems can be critical to maintaining optimal performance levels.

Before physical assembly, thermal simulation software can model heat distribution in an Lm380 circuit in various configurations. This enables designers to quickly identify hotspots and assess the efficacy of various cooling solutions. By employing these advanced modeling techniques, engineers can optimize the heatsink design before the fabrication process and avoid costly redesigns down the line.

Aside from external cooling solutions, enhancing the circuit design itself can prove beneficial in thermal management. For instance, decreasing the power output requirements through circuit optimization can lead to less heat generation. The choice of surrounding passive components can also affect overall heat dissipation, as can the layout of the PCB. Strategically placing heat-sensitive components away from heat-generating elements can promote a more effective thermal environment.

To further understand the significance of heatsinks, it is valuable to examine some case studies that underscore successful heat management in Lm380 applications. These examples demonstrate how careful planning can lead to the optimized performance of audio systems:

In a recent home theater project, engineers implemented an Lm380-based amplifier that required extensive cooling due to high output demands during peak usage. By integrating a significant aluminum heatsink with multiple fins and pairing it with a small, low-noise fan, the team managed to keep component temperatures within safe limits. The result was an audio system that functioned flawlessly even during prolonged use without any risk of thermal failure. This implementation proved crucial in ensuring that sound quality remained high without being compromised by heat-induced distortion.

In automotive applications, the space constraints often pose challenges to effective thermal management. An automotive audio system upgrade incorporated an Lm380 amplifier with a specialized heatsink that featured copper inserts for enhanced thermal connectivity. The design aimed to maximize airflow between components, utilizing the vehicle's natural venting during travel. This combination resulted in exceptional audio clarity with minimum heat-related interruptions, significantly improving the ride experience for users.

Looking ahead, heatsink technology continues to evolve in response to increasingly demanding thermal management needs. Several trends are emerging that will likely shape how heatsinks are utilized in audio amplification circuits and other high-power applications:

Advancements in 3D printing technology now allow for the creation of heatsinks with complex geometries that were previously impossible or prohibitively expensive to manufacture. This capability permits finer customization to fit specific applications, allowing for optimized airflow paths and increased surface areas to maximize heat dissipation.

Phased array cooling systems represent an innovative approach to thermal management involving a series of small, independently-controlled cooling elements that can target hotspots more effectively than traditional methods. This technology could revolutionize how heatsinks are designed for audio amplifiers by adapting cooling efforts based on real-time thermal feedback.

Integration of IoT (Internet of Things) technologies into heatsink design is another promising development. Smart heatsinks could monitor temperatures and dynamically adjust cooling efforts depending on the circuit demand. Such intelligent cooling systems can help in extending the lifetime of components while ensuring maximum performance is consistently maintained.

In conclusion, integrating an Lm380 heatsink is a proactive measure in optimizing and safeguarding the performance of audio amplifier circuits. Selecting the right heatsink involves considering factors like material, size, and installation methods. Thoughtful thermal management not only enhances the durability of the circuit but also prevents disruptions in audio performance, thereby maintaining user satisfaction and reliability in electronic device operation. By paying keen attention to these aspects, electronics professionals can ensure the longevity and efficacy of their designs. Furthermore, as technology continues to evolve, the strategies and tools available for thermal management will allow for ever greater performance and capability in modern audio applications, enabling richer experiences for users.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!